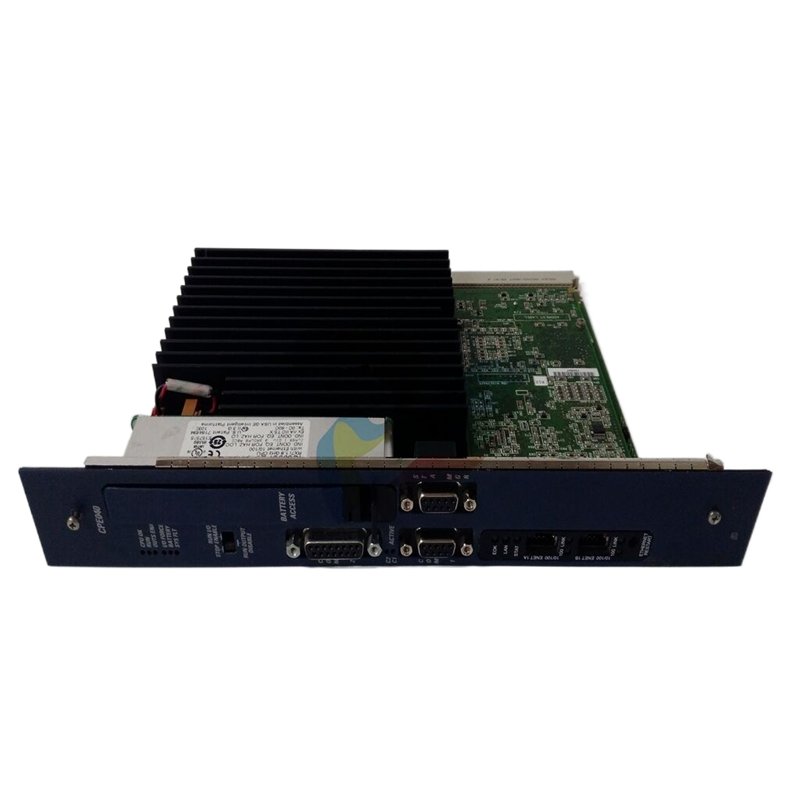

GE Fanuc IS215VCMIH2CC | Communication Card

Introducing the GE Fanuc Series: Reliability and Precision in Automation

The GE Fanuc series stands as a testament to cutting-edge engineering and innovation in the realm of automation. With a legacy built on trust and performance, GE Fanuc products are designed to meet the rigorous demands of various industries, providing unparalleled reliability and efficiency. In this detailed overview, we will delve into the key technical features of the GE Fanuc series, highlight usage scenarios, compare it with other models, and reference related products that complement the GE automation ecosystem.

Key Technical Features

At the heart of the GE Fanuc series is its robust architecture, designed to support a wide range of applications. The series boasts high-speed processing capabilities, which ensure rapid data acquisition and analysis. This is essential in environments where split-second decisions can impact operational efficiency.

1. **Advanced Communication Protocols**: GE Fanuc products integrate seamlessly with various communication protocols, including Ethernet, Modbus, and Profibus. This versatility allows for easy connectivity with existing systems, minimizing downtime during integration.

2. **Scalability**: The modular design of GE Fanuc systems allows for easy scalability. Businesses can start with a basic configuration and expand as their needs grow, ensuring a cost-effective solution that adapts to changing requirements.

3. **Robust I/O Options**: The series offers a range of input and output modules, enabling precise control over machinery and processes. Users can choose from digital, analog, and specialty I/O options to tailor their systems to specific operational needs.

4. **User-Friendly Interface**: The GE Fanuc series features intuitive software and hardware interfaces, simplifying programming and operation. This ease of use accelerates training for personnel and reduces the learning curve.

5. **Durability and Reliability**: Built to endure harsh industrial environments, GE Fanuc products are designed with robust materials that resist dust, moisture, and temperature extremes. This durability translates into longer service life and lower maintenance costs.

Usage Scenarios

GE Fanuc products are utilized across various sectors, including manufacturing, energy, transportation, and healthcare. Some common usage scenarios include:

– **Manufacturing Automation**: In a manufacturing setting, GE Fanuc systems can control assembly lines, monitor production processes, and manage quality assurance checks. The ability to quickly adapt to changes in production demands makes these systems invaluable.

– **Energy Management**: Power generation facilities leverage GE Fanuc products to monitor and control turbines, ensure grid stability, and optimize energy distribution. The advanced data analytics capabilities enable predictive maintenance, reducing downtime and operational costs.

– **Transportation Systems**: GE Fanuc automation solutions are instrumental in traffic management systems, ensuring efficient flow and safety. They can also be used in rail systems for monitoring and control, enhancing safety and reliability.

– **Healthcare Automation**: In healthcare, GE Fanuc products help automate laboratory processes, manage patient data, and streamline operations in medical facilities. This leads to improved patient care and operational efficiency.

Comparison with Other Models

When comparing the GE Fanuc series to other models within the GE automation products line, it becomes clear that the Fanuc series stands out in terms of versatility and performance. For instance, while models like the GE IS200TBCIH1BBC and GE IS220PPROS1B offer specific functionalities geared towards particular applications, the GE Fanuc series provides a comprehensive solution that can adapt to various industries and applications.

In contrast to the GE IC697MDL250, which serves as a reliable I/O module, the GE Fanuc series incorporates advanced processing capabilities, making it a more suitable choice for complex automation tasks. Additionally, the GE IS215UCVEH2AB, while effective for specific control applications, may not offer the same level of scalability and customization as the GE Fanuc series.

Reference to Related Models

For those looking to expand their automation capabilities with GE products, consider these related models:

1. **GE IS200TPROH1BBB**: A powerful processing unit that complements the GE Fanuc series with advanced control features.

2. **GE IC660ELB912G**: A reliable input/output module that enhances the system's connectivity options.

3. **GE DS200CTBAG1ADD**: A versatile control board that integrates seamlessly with GE Fanuc systems.

4. **GE IC670CHS001E**: An essential component for communication within GE automation environments.

5. **GE IS200EPSMG2ADC**: A critical module for energy management applications.

6. **GE 531X307LTBAJG1**: A robust option for specialized control functions.

7. **GE IS230SNIDH1A**: An advanced monitoring unit that complements the functionality of GE Fanuc products.

8. **GE IS220PRTDH1A**: A precision measurement module ideal for process control.

9. **GE IC693CPU374**: A powerful CPU that can be integrated with the GE Fanuc series for enhanced processing capabilities.

10. **GE IS200DSPXH1DBC**: A digital signal processing unit that works alongside the GE Fanuc series for real-time data analysis.

Conclusion

The GE Fanuc series exemplifies the pinnacle of automation technology, offering a blend of reliability, scalability, and advanced features. Whether it’s in manufacturing, energy management, transportation, or healthcare, GE Fanuc products provide the solutions needed to enhance operational efficiency and drive innovation. With the ability to integrate seamlessly with other GE automation products, the GE Fanuc series is the ideal choice for businesses looking to optimize their automation systems. Choose GE Fanuc for unparalleled performance and reliability in your automation endeavors.

The above parameters are for reference only. Please contact our technical team for precise selection.

The GE Fanuc series stands as a testament to cutting-edge engineering and innovation in the realm of automation. With a legacy built on trust and performance, GE Fanuc products are designed to meet the rigorous demands of various industries, providing unparalleled reliability and efficiency. In this detailed overview, we will delve into the key technical features of the GE Fanuc series, highlight usage scenarios, compare it with other models, and reference related products that complement the GE automation ecosystem.

Key Technical Features

At the heart of the GE Fanuc series is its robust architecture, designed to support a wide range of applications. The series boasts high-speed processing capabilities, which ensure rapid data acquisition and analysis. This is essential in environments where split-second decisions can impact operational efficiency.

1. **Advanced Communication Protocols**: GE Fanuc products integrate seamlessly with various communication protocols, including Ethernet, Modbus, and Profibus. This versatility allows for easy connectivity with existing systems, minimizing downtime during integration.

2. **Scalability**: The modular design of GE Fanuc systems allows for easy scalability. Businesses can start with a basic configuration and expand as their needs grow, ensuring a cost-effective solution that adapts to changing requirements.

3. **Robust I/O Options**: The series offers a range of input and output modules, enabling precise control over machinery and processes. Users can choose from digital, analog, and specialty I/O options to tailor their systems to specific operational needs.

4. **User-Friendly Interface**: The GE Fanuc series features intuitive software and hardware interfaces, simplifying programming and operation. This ease of use accelerates training for personnel and reduces the learning curve.

5. **Durability and Reliability**: Built to endure harsh industrial environments, GE Fanuc products are designed with robust materials that resist dust, moisture, and temperature extremes. This durability translates into longer service life and lower maintenance costs.

Usage Scenarios

GE Fanuc products are utilized across various sectors, including manufacturing, energy, transportation, and healthcare. Some common usage scenarios include:

– **Manufacturing Automation**: In a manufacturing setting, GE Fanuc systems can control assembly lines, monitor production processes, and manage quality assurance checks. The ability to quickly adapt to changes in production demands makes these systems invaluable.

– **Energy Management**: Power generation facilities leverage GE Fanuc products to monitor and control turbines, ensure grid stability, and optimize energy distribution. The advanced data analytics capabilities enable predictive maintenance, reducing downtime and operational costs.

– **Transportation Systems**: GE Fanuc automation solutions are instrumental in traffic management systems, ensuring efficient flow and safety. They can also be used in rail systems for monitoring and control, enhancing safety and reliability.

– **Healthcare Automation**: In healthcare, GE Fanuc products help automate laboratory processes, manage patient data, and streamline operations in medical facilities. This leads to improved patient care and operational efficiency.

Comparison with Other Models

When comparing the GE Fanuc series to other models within the GE automation products line, it becomes clear that the Fanuc series stands out in terms of versatility and performance. For instance, while models like the GE IS200TBCIH1BBC and GE IS220PPROS1B offer specific functionalities geared towards particular applications, the GE Fanuc series provides a comprehensive solution that can adapt to various industries and applications.

In contrast to the GE IC697MDL250, which serves as a reliable I/O module, the GE Fanuc series incorporates advanced processing capabilities, making it a more suitable choice for complex automation tasks. Additionally, the GE IS215UCVEH2AB, while effective for specific control applications, may not offer the same level of scalability and customization as the GE Fanuc series.

Reference to Related Models

For those looking to expand their automation capabilities with GE products, consider these related models:

1. **GE IS200TPROH1BBB**: A powerful processing unit that complements the GE Fanuc series with advanced control features.

2. **GE IC660ELB912G**: A reliable input/output module that enhances the system's connectivity options.

3. **GE DS200CTBAG1ADD**: A versatile control board that integrates seamlessly with GE Fanuc systems.

4. **GE IC670CHS001E**: An essential component for communication within GE automation environments.

5. **GE IS200EPSMG2ADC**: A critical module for energy management applications.

6. **GE 531X307LTBAJG1**: A robust option for specialized control functions.

7. **GE IS230SNIDH1A**: An advanced monitoring unit that complements the functionality of GE Fanuc products.

8. **GE IS220PRTDH1A**: A precision measurement module ideal for process control.

9. **GE IC693CPU374**: A powerful CPU that can be integrated with the GE Fanuc series for enhanced processing capabilities.

10. **GE IS200DSPXH1DBC**: A digital signal processing unit that works alongside the GE Fanuc series for real-time data analysis.

Conclusion

The GE Fanuc series exemplifies the pinnacle of automation technology, offering a blend of reliability, scalability, and advanced features. Whether it’s in manufacturing, energy management, transportation, or healthcare, GE Fanuc products provide the solutions needed to enhance operational efficiency and drive innovation. With the ability to integrate seamlessly with other GE automation products, the GE Fanuc series is the ideal choice for businesses looking to optimize their automation systems. Choose GE Fanuc for unparalleled performance and reliability in your automation endeavors.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.