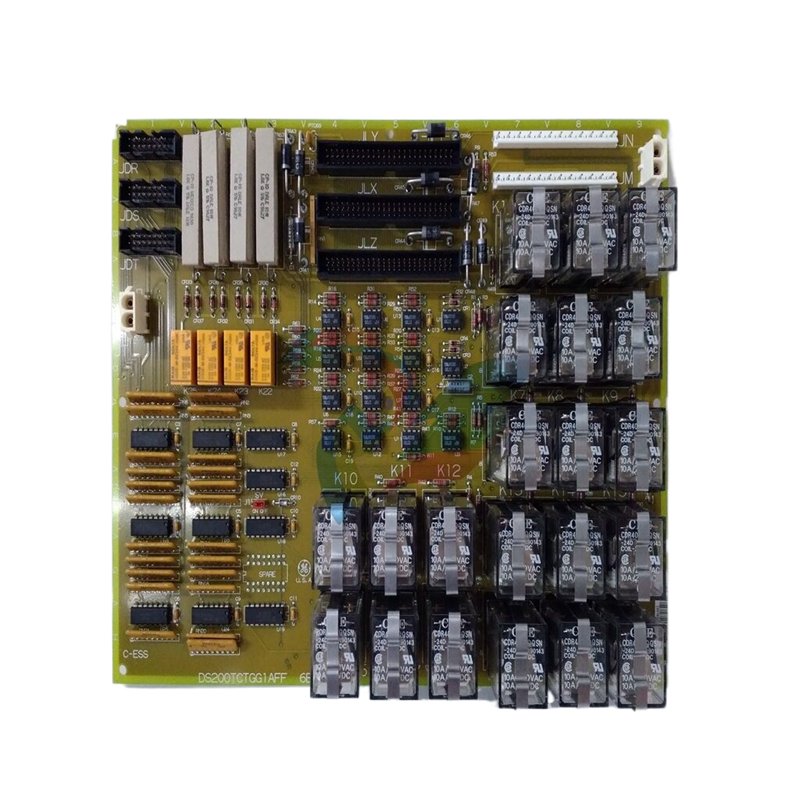

GE Fanuc IC693MDL940M PAC Systems RX3i I/O Module

Introducing the GE Fanuc Series: Elevating Automation Performance

The GE Fanuc series is at the forefront of industrial automation technology, offering a suite of advanced solutions designed to optimize operational efficiency and reliability. With a legacy of innovation, GE Fanuc products are synonymous with quality, durability, and cutting-edge technology. This product description will delve into the key technical features of the GE Fanuc series, explore various usage scenarios, compare with other models, and highlight related models within the GE brand.

Key Technical Features

The GE Fanuc models are packed with advanced features that cater to a wide array of industrial applications. Some of the standout technical specifications include:

1. **Powerful Processing Capabilities**: The GE Fanuc series boasts high-performance processors that ensure quick data processing and real-time control. Models like the GE IS220PPROS1B and GE IC693CPU374 exemplify this performance, handling complex tasks with ease.

2. **Versatile I/O Options**: With a variety of input/output configurations, the GE Fanuc models accommodate diverse sensor and actuator types. This flexibility is evident in models such as the GE IC697MDL250 and GE IS215UCVEH2AB, which support a broad range of industrial protocols and connectivity options.

3. **Robust Communication Protocols**: GE Fanuc products support multiple communication protocols, ensuring seamless integration with existing systems. The GE IS200TBCIH1BBC and GE 369-HI-0-M-0-0-0 models, for instance, allow for easy networking and data sharing, enhancing overall system efficiency.

4. **Enhanced Diagnostic Features**: Built-in diagnostic tools in the GE Fanuc series, such as those found in the GE IS200TPROH1BCB, provide real-time monitoring and troubleshooting, enabling users to quickly identify and resolve issues, thus minimizing downtime.

5. **Scalability and Modularity**: The modular design of GE Fanuc products allows for easy scalability. Whether you need to expand your system or upgrade components, models like the GE IC698ACC701 and GE IS200DSPXH1DBD make it simple to adapt to changing operational needs.

Usage Scenarios

The versatility of GE Fanuc products makes them suitable for a variety of industrial applications. Here are a few scenarios where these automation solutions shine:

1. **Manufacturing**: In manufacturing environments, the GE Fanuc series can manage complex assembly lines, monitor equipment performance, and facilitate predictive maintenance, ensuring optimal productivity and minimal downtime.

2. **Energy Management**: GE Fanuc products are essential in the energy sector, where they control and monitor power distribution systems, manage grid operations, and ensure efficient resource utilization.

3. **Transportation Systems**: The GE Fanuc series is instrumental in managing traffic control systems, ensuring timely responses to changing traffic conditions, and enhancing overall transportation safety.

4. **Water Treatment**: For water treatment facilities, the GE Fanuc models provide real-time monitoring and control of water quality, chemical dosing, and equipment status, ensuring compliance with regulatory standards.

5. **Oil and Gas**: In the oil and gas industry, GE Fanuc products help monitor drilling operations, manage pipeline systems, and ensure safety protocols are followed, all while optimizing resource extraction.

Comparison with Other Models

When comparing GE Fanuc models to others in the marketplace, their reliability and performance stand out significantly. For instance, while models from competitors may offer similar processing capabilities, GE Fanuc's robust diagnostic features and superior modularity provide an edge in operational efficiency.

For example, the GE IS200EPSMG2ADC outperforms many standard PLCs in terms of communication flexibility and processing speed, making it an ideal choice for complex industrial environments. In contrast, entry-level models such as the GE CT7P70500470CW24, while effective for basic applications, may lack the advanced features necessary for high-demand tasks.

The GE IS200TBCIH1BBC and GE IS220PAICH2A models showcase advanced integration capabilities that allow them to interface seamlessly with other GE automation products and third-party systems, providing an advantage over less flexible alternatives on the market.

Related Models

To give you a broader perspective on the GE Fanuc series, here are ten related models that complement the offerings in this line:

1. **GE IC660ELB912G** – A versatile I/O controller known for its reliability.

2. **GE IS200TPROH1BBB** – A high-performance processor with advanced control capabilities.

3. **GE IS230SNIDH1A** – A specialized module for precise control applications.

4. **GE DS200CTBAG1ADD** – A powerful communication module enhancing connectivity.

5. **GE IC697MDL653** – An I/O module that supports a wide range of applications.

6. **GE HE693STP110** – A stepper motor control that integrates with various systems.

7. **GE IS215UCVEH2AB** – A versatile control module with enhanced user interface options.

8. **GE IC693CPU341** – An advanced CPU known for its processing power and reliability.

9. **GE IS220PRTDH1A** – A temperature monitoring module ideal for various industrial settings.

10. **GE DS200SDCCG1AGD** – A high-speed communication module for critical data transfer.

In conclusion, the GE Fanuc series stands as a leader in the realm of industrial automation, combining robust technical features with versatile applications. Its ability to enhance operational efficiency, coupled with exceptional reliability, makes it the preferred choice for businesses looking to optimize their processes. With a wide range of related models and a commitment to innovation, GE automation products continue to shape the future of industrial technology. For those seeking unparalleled performance in automation, the GE Fanuc series is the ultimate solution.

The above parameters are for reference only. Please contact our technical team for precise selection.

The GE Fanuc series is at the forefront of industrial automation technology, offering a suite of advanced solutions designed to optimize operational efficiency and reliability. With a legacy of innovation, GE Fanuc products are synonymous with quality, durability, and cutting-edge technology. This product description will delve into the key technical features of the GE Fanuc series, explore various usage scenarios, compare with other models, and highlight related models within the GE brand.

Key Technical Features

The GE Fanuc models are packed with advanced features that cater to a wide array of industrial applications. Some of the standout technical specifications include:

1. **Powerful Processing Capabilities**: The GE Fanuc series boasts high-performance processors that ensure quick data processing and real-time control. Models like the GE IS220PPROS1B and GE IC693CPU374 exemplify this performance, handling complex tasks with ease.

2. **Versatile I/O Options**: With a variety of input/output configurations, the GE Fanuc models accommodate diverse sensor and actuator types. This flexibility is evident in models such as the GE IC697MDL250 and GE IS215UCVEH2AB, which support a broad range of industrial protocols and connectivity options.

3. **Robust Communication Protocols**: GE Fanuc products support multiple communication protocols, ensuring seamless integration with existing systems. The GE IS200TBCIH1BBC and GE 369-HI-0-M-0-0-0 models, for instance, allow for easy networking and data sharing, enhancing overall system efficiency.

4. **Enhanced Diagnostic Features**: Built-in diagnostic tools in the GE Fanuc series, such as those found in the GE IS200TPROH1BCB, provide real-time monitoring and troubleshooting, enabling users to quickly identify and resolve issues, thus minimizing downtime.

5. **Scalability and Modularity**: The modular design of GE Fanuc products allows for easy scalability. Whether you need to expand your system or upgrade components, models like the GE IC698ACC701 and GE IS200DSPXH1DBD make it simple to adapt to changing operational needs.

Usage Scenarios

The versatility of GE Fanuc products makes them suitable for a variety of industrial applications. Here are a few scenarios where these automation solutions shine:

1. **Manufacturing**: In manufacturing environments, the GE Fanuc series can manage complex assembly lines, monitor equipment performance, and facilitate predictive maintenance, ensuring optimal productivity and minimal downtime.

2. **Energy Management**: GE Fanuc products are essential in the energy sector, where they control and monitor power distribution systems, manage grid operations, and ensure efficient resource utilization.

3. **Transportation Systems**: The GE Fanuc series is instrumental in managing traffic control systems, ensuring timely responses to changing traffic conditions, and enhancing overall transportation safety.

4. **Water Treatment**: For water treatment facilities, the GE Fanuc models provide real-time monitoring and control of water quality, chemical dosing, and equipment status, ensuring compliance with regulatory standards.

5. **Oil and Gas**: In the oil and gas industry, GE Fanuc products help monitor drilling operations, manage pipeline systems, and ensure safety protocols are followed, all while optimizing resource extraction.

Comparison with Other Models

When comparing GE Fanuc models to others in the marketplace, their reliability and performance stand out significantly. For instance, while models from competitors may offer similar processing capabilities, GE Fanuc's robust diagnostic features and superior modularity provide an edge in operational efficiency.

For example, the GE IS200EPSMG2ADC outperforms many standard PLCs in terms of communication flexibility and processing speed, making it an ideal choice for complex industrial environments. In contrast, entry-level models such as the GE CT7P70500470CW24, while effective for basic applications, may lack the advanced features necessary for high-demand tasks.

The GE IS200TBCIH1BBC and GE IS220PAICH2A models showcase advanced integration capabilities that allow them to interface seamlessly with other GE automation products and third-party systems, providing an advantage over less flexible alternatives on the market.

Related Models

To give you a broader perspective on the GE Fanuc series, here are ten related models that complement the offerings in this line:

1. **GE IC660ELB912G** – A versatile I/O controller known for its reliability.

2. **GE IS200TPROH1BBB** – A high-performance processor with advanced control capabilities.

3. **GE IS230SNIDH1A** – A specialized module for precise control applications.

4. **GE DS200CTBAG1ADD** – A powerful communication module enhancing connectivity.

5. **GE IC697MDL653** – An I/O module that supports a wide range of applications.

6. **GE HE693STP110** – A stepper motor control that integrates with various systems.

7. **GE IS215UCVEH2AB** – A versatile control module with enhanced user interface options.

8. **GE IC693CPU341** – An advanced CPU known for its processing power and reliability.

9. **GE IS220PRTDH1A** – A temperature monitoring module ideal for various industrial settings.

10. **GE DS200SDCCG1AGD** – A high-speed communication module for critical data transfer.

In conclusion, the GE Fanuc series stands as a leader in the realm of industrial automation, combining robust technical features with versatile applications. Its ability to enhance operational efficiency, coupled with exceptional reliability, makes it the preferred choice for businesses looking to optimize their processes. With a wide range of related models and a commitment to innovation, GE automation products continue to shape the future of industrial technology. For those seeking unparalleled performance in automation, the GE Fanuc series is the ultimate solution.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.