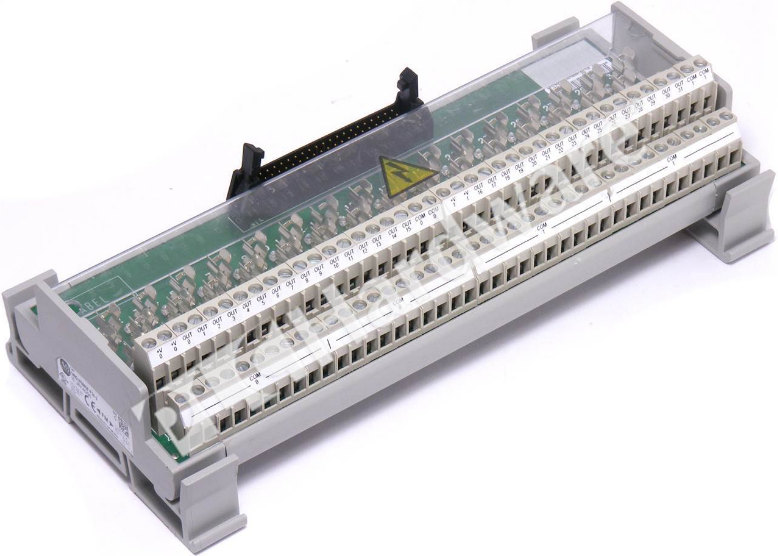

GE FANUC IC693PWR321T High-Power Density Modular Power Supply

Introducing the GE FANUC, a leading-edge solution in the realm of industrial automation. Renowned for its reliability and precision, the GE FANUC is engineered to meet the burgeoning demands of various industries, ensuring optimal performance in automation processes. With its robust technical features, versatile usage scenarios, and a rich legacy of excellence, the GE FANUC stands out as a premier choice for manufacturers and automation professionals.

Key Technical Features

The GE FANUC is equipped with an array of high-performance features designed to enhance functionality and streamline operations. Among its key specifications are:

1. **Advanced Processing Power**: With its superior microprocessor technology, the GE FANUC offers high-speed processing capabilities that allow for rapid data handling and real-time control, making it ideal for complex automation tasks.

2. **Versatile Communication Protocols**: Supporting a variety of communication standards, the GE FANUC can seamlessly integrate with other devices and systems, including Ethernet, Serial, and more. This flexibility ensures compatibility with existing factory automation infrastructure.

3. **Scalability**: Designed to grow with your business, the GE FANUC can be easily expanded by adding modules or connecting to additional systems, making it suitable for both small-scale operations and large manufacturing facilities.

4. **Robust I/O Capabilities**: The GE FANUC boasts an extensive array of input/output options, enabling it to interface with various sensors, actuators, and other field devices. This feature allows for comprehensive control and monitoring of production processes.

5. **User-Friendly Interface**: With an intuitive interface, the GE FANUC simplifies programming and operation, allowing users to easily configure and manage automation tasks without extensive training.

Usage Scenarios

The versatility of the GE FANUC makes it an ideal choice for a wide range of applications across various industries. It excels in:

1. **Manufacturing Automation**: The GE FANUC can control production lines, ensuring efficiency and precision in processes such as assembly, packaging, and material handling.

2. **Process Control**: In industries such as oil and gas, chemicals, and pharmaceuticals, the GE FANUC enables real-time monitoring and control of complex processes, ensuring safety and compliance with industry regulations.

3. **Building Automation**: From HVAC systems to lighting control, the GE FANUC can streamline building management systems, enhancing energy efficiency and occupant comfort.

4. **Robotics Integration**: The GE FANUC is compatible with robotic systems, allowing for advanced automation solutions in applications such as welding, painting, and material handling.

5. **Data Acquisition**: With its robust data handling capabilities, the GE FANUC can collect and analyze data from various sources, providing valuable insights for process optimization and decision-making.

Comparison with Other Models

When comparing the GE FANUC with other models in the GE automation products lineup, its unique features and capabilities become evident. For instance, while models like the GE IS200TBCIH1BBC and GE IS220PAICH2A offer specialized functions, the GE FANUC provides a more comprehensive solution that balances speed, scalability, and ease of use.

In contrast to models such as the GE IS215UCVEH2AB and GE IS200TPROH1BBB, which are tailored for specific applications, the GE FANUC’s versatility makes it suitable for a broader range of industries and applications. Additionally, while the GE IC697MDL250 and GE IC670CHS001E provide reliable performance, the advanced processing power and communication protocols of the GE FANUC set it apart, making it a more future-proof investment.

Related Models

For those exploring the GE automation products portfolio, several related models complement the GE FANUC, including:

1. GE IS200TBCIH1BBC

2. GE IS220PPROS1B

3. GE IS220PAICH2A

4. GE IS215UCVEH2AB

5. GE IS200DSPXH1DBC

6. GE DS200CTBAG1ADD

7. GE IC670MDL740J

8. GE IC693CPU374

9. GE IC698ACC701

10. GE 369-HI-0-M-0-0-0

Each of these models offers specific features and functionalities that can enhance automation systems, making it essential to assess your operational requirements when selecting the right solution.

Conclusion

The GE FANUC is an exemplary model that embodies the essence of GE’s commitment to innovation in automation technology. With its powerful processing capabilities, versatile communication options, and user-friendly interface, it stands ready to tackle the challenges of modern industrial automation. Whether you are looking to optimize manufacturing processes, improve data acquisition, or enhance robotics integration, the GE FANUC is your trusted partner in achieving operational excellence.

As industries continue to evolve, the need for reliable and advanced automation solutions becomes paramount. Invest in the GE FANUC and experience the difference that quality engineering can make in your automation endeavors. Discover the full potential of GE automation products and propel your business to new heights today.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE FANUC is equipped with an array of high-performance features designed to enhance functionality and streamline operations. Among its key specifications are:

1. **Advanced Processing Power**: With its superior microprocessor technology, the GE FANUC offers high-speed processing capabilities that allow for rapid data handling and real-time control, making it ideal for complex automation tasks.

2. **Versatile Communication Protocols**: Supporting a variety of communication standards, the GE FANUC can seamlessly integrate with other devices and systems, including Ethernet, Serial, and more. This flexibility ensures compatibility with existing factory automation infrastructure.

3. **Scalability**: Designed to grow with your business, the GE FANUC can be easily expanded by adding modules or connecting to additional systems, making it suitable for both small-scale operations and large manufacturing facilities.

4. **Robust I/O Capabilities**: The GE FANUC boasts an extensive array of input/output options, enabling it to interface with various sensors, actuators, and other field devices. This feature allows for comprehensive control and monitoring of production processes.

5. **User-Friendly Interface**: With an intuitive interface, the GE FANUC simplifies programming and operation, allowing users to easily configure and manage automation tasks without extensive training.

Usage Scenarios

The versatility of the GE FANUC makes it an ideal choice for a wide range of applications across various industries. It excels in:

1. **Manufacturing Automation**: The GE FANUC can control production lines, ensuring efficiency and precision in processes such as assembly, packaging, and material handling.

2. **Process Control**: In industries such as oil and gas, chemicals, and pharmaceuticals, the GE FANUC enables real-time monitoring and control of complex processes, ensuring safety and compliance with industry regulations.

3. **Building Automation**: From HVAC systems to lighting control, the GE FANUC can streamline building management systems, enhancing energy efficiency and occupant comfort.

4. **Robotics Integration**: The GE FANUC is compatible with robotic systems, allowing for advanced automation solutions in applications such as welding, painting, and material handling.

5. **Data Acquisition**: With its robust data handling capabilities, the GE FANUC can collect and analyze data from various sources, providing valuable insights for process optimization and decision-making.

Comparison with Other Models

When comparing the GE FANUC with other models in the GE automation products lineup, its unique features and capabilities become evident. For instance, while models like the GE IS200TBCIH1BBC and GE IS220PAICH2A offer specialized functions, the GE FANUC provides a more comprehensive solution that balances speed, scalability, and ease of use.

In contrast to models such as the GE IS215UCVEH2AB and GE IS200TPROH1BBB, which are tailored for specific applications, the GE FANUC’s versatility makes it suitable for a broader range of industries and applications. Additionally, while the GE IC697MDL250 and GE IC670CHS001E provide reliable performance, the advanced processing power and communication protocols of the GE FANUC set it apart, making it a more future-proof investment.

Related Models

For those exploring the GE automation products portfolio, several related models complement the GE FANUC, including:

1. GE IS200TBCIH1BBC

2. GE IS220PPROS1B

3. GE IS220PAICH2A

4. GE IS215UCVEH2AB

5. GE IS200DSPXH1DBC

6. GE DS200CTBAG1ADD

7. GE IC670MDL740J

8. GE IC693CPU374

9. GE IC698ACC701

10. GE 369-HI-0-M-0-0-0

Each of these models offers specific features and functionalities that can enhance automation systems, making it essential to assess your operational requirements when selecting the right solution.

Conclusion

The GE FANUC is an exemplary model that embodies the essence of GE’s commitment to innovation in automation technology. With its powerful processing capabilities, versatile communication options, and user-friendly interface, it stands ready to tackle the challenges of modern industrial automation. Whether you are looking to optimize manufacturing processes, improve data acquisition, or enhance robotics integration, the GE FANUC is your trusted partner in achieving operational excellence.

As industries continue to evolve, the need for reliable and advanced automation solutions becomes paramount. Invest in the GE FANUC and experience the difference that quality engineering can make in your automation endeavors. Discover the full potential of GE automation products and propel your business to new heights today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.