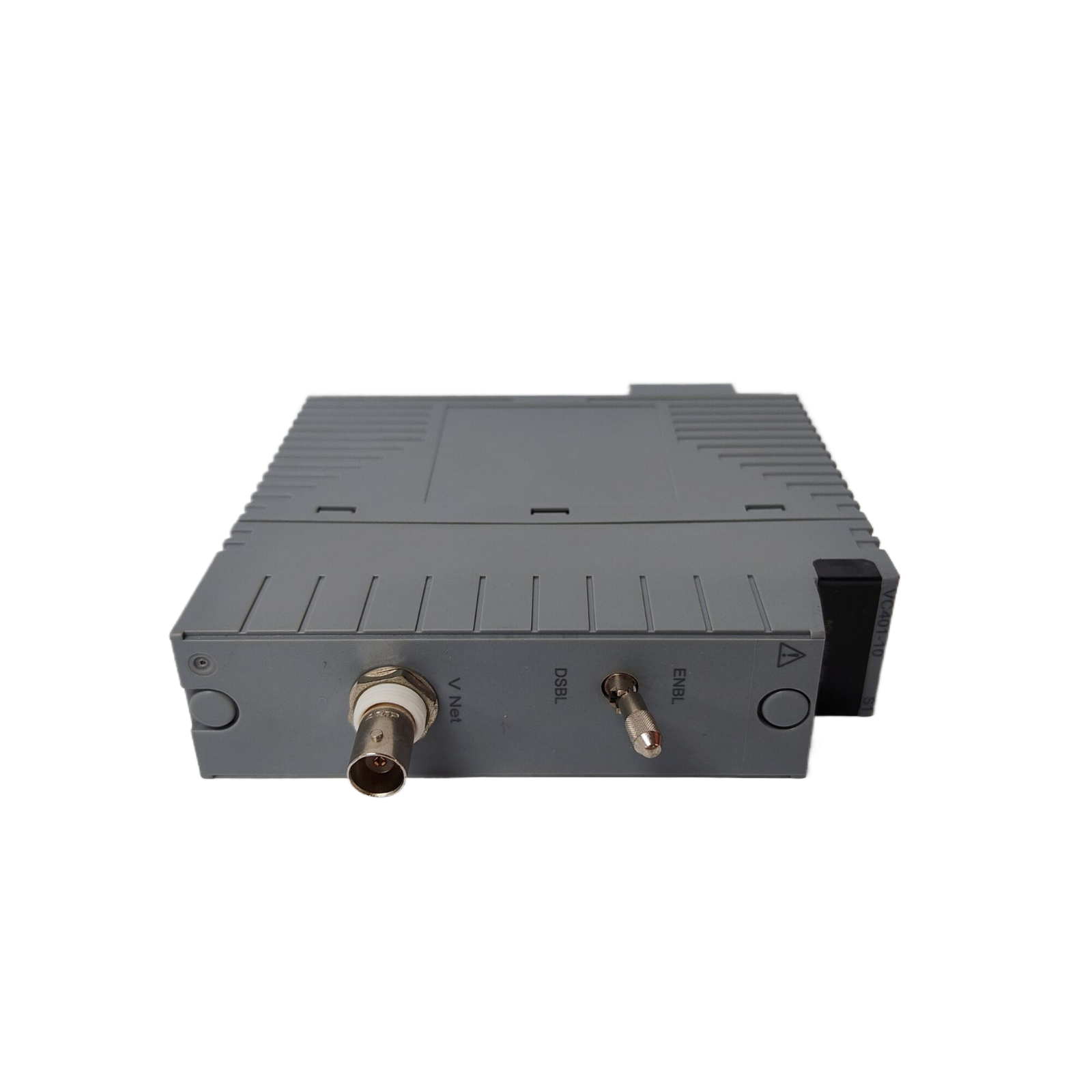

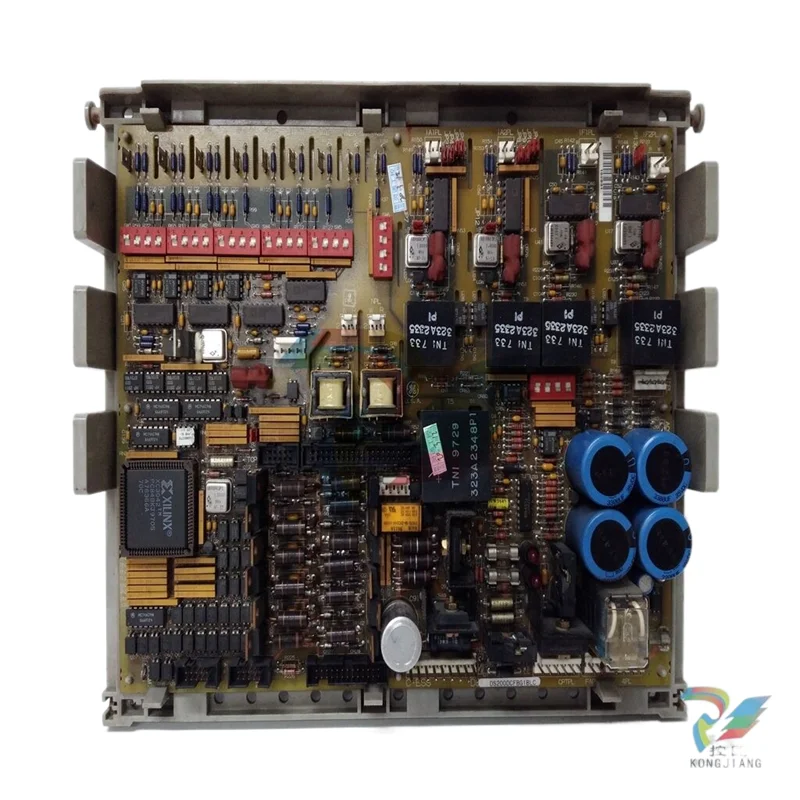

GE SR750 P5-G5-S5-HI-A20-R-E Protective Relay

Introducing the GE SR750: A Benchmark in GE Automation Products

When it comes to reliability, performance, and advanced technology in the automation industry, GE has consistently delivered cutting-edge solutions. The GE SR750 stands as a testament to this legacy, offering unmatched capabilities tailored to meet the demands of modern industrial environments. This product description delves into the key technical features, usage scenarios, comparisons with other models, and highlights related models, showcasing why the GE SR750 is an essential addition to any automation setup.

Key Technical Features

The GE SR750 is engineered with precision, featuring a robust design that enhances its operational efficiency. Key technical features include:

1. **High Processing Power**: The SR750 is equipped with a powerful processor that ensures rapid data handling and real-time analytics. Its advanced architecture allows it to manage complex automation tasks without compromising speed or accuracy.

2. **Modular Design**: The SR750 embraces a modular design, allowing for easy scalability. This feature enables users to customize their systems according to specific operational requirements, enhancing flexibility in various applications.

3. **Integrated Communication Protocols**: The device supports multiple communication protocols, including Ethernet/IP and Modbus TCP, facilitating seamless integration with a wide range of devices and systems. This interoperability is crucial for modern industrial environments where diverse equipment must work together harmoniously.

4. **Enhanced Safety Features**: Safety is paramount in industrial settings. The GE SR750 incorporates advanced safety features, including built-in redundancy and fail-safe mechanisms, ensuring uninterrupted operation and minimal downtime.

5. **User-Friendly Interface**: The SR750 boasts an intuitive user interface that simplifies configuration and monitoring. Users can easily navigate through settings, access data, and make adjustments in real time, enhancing overall operational efficiency.

6. **Rugged Durability**: Designed for harsh environments, the SR750 withstands extreme temperatures, vibrations, and dust, making it suitable for a variety of industrial applications. Its rugged construction ensures longevity and reliability, even in challenging conditions.

Usage Scenarios

The GE SR750 is versatile and adaptable to numerous industrial applications, making it ideal for a wide range of sectors, including:

1. **Manufacturing**: In manufacturing plants, the SR750 can manage production lines, monitor machinery, and ensure optimal performance, contributing to increased productivity and reduced operational costs.

2. **Oil and Gas**: The SR750 is well-suited for the oil and gas industry, where it can oversee drilling operations, manage equipment, and ensure compliance with safety regulations, all while maintaining real-time data analytics.

3. **Water Treatment**: In water treatment facilities, the SR750 can control various processes, from filtration to chemical dosing, ensuring that water quality meets regulatory standards while optimizing resource usage.

4. **Transportation**: The device can be employed in transportation systems to manage traffic signals, monitor vehicle flow, and enhance public safety through efficient control mechanisms.

5. **Utilities**: The SR750 can play a critical role in utility management, monitoring energy consumption, controlling distribution networks, and maintaining system integrity across vast infrastructures.

Comparison with Other Models

When comparing the GE SR750 with other models within the GE automation products lineup, several distinctions emerge. For instance, while the GE IS200TBCIH1BBC and GE IS220PPROS1B are robust options for specific applications, the SR750 surpasses them in processing power and modularity, making it more suitable for complex and scalable environments.

Similarly, models like the GE IC697MDL250 and GE DS200SDCCG1AGD may offer specialized features, but the SR750's comprehensive integration capabilities and enhanced safety mechanisms provide a competitive edge. Its versatility sets it apart from the GE IS215UCVEH2AB and GE 369-HI-0-M-0-0-0, which are tailored for niche applications.

Moreover, while the GE IC693CPU374 and GE IC698CMX016 are reliable options, the SR750's strengths in communication protocols and user interface design elevate it to a higher tier of automation products, catering to the evolving needs of industries.

Related Models

For those exploring the capabilities of the GE SR750, several related models are noteworthy:

1. **GE IS200TBCIH1BBC**: A solid choice for control applications, offering reliable performance.

2. **GE IS220PPROS1B**: Known for its advanced processing capabilities in specific automation tasks.

3. **GE CT7P70500470CW24**: A versatile model ideal for various industrial applications.

4. **GE EVMECNTM13**: Tailored for energy management solutions.

5. **GE IS220PAICH2A**: Focused on process automation with a robust feature set.

6. **GE IC697MDL250**: A reliable option for discrete input/output tasks.

7. **GE DS200CTBAG1ADD**: Suited for control systems with a focus on diagnostics.

8. **GE IS200EPSMG2ADC**: Designed for enhanced safety and operational reliability in critical systems.

9. **GE IC670MDL740J**: Offers high-performance control in rugged environments.

10. **GE IS230SNIDH1A**: Ideal for advanced networking applications in automation.

Conclusion

The GE SR750 is a groundbreaking addition to the suite of GE automation products, offering unparalleled performance, modularity, and reliability for diverse industrial applications. Its advanced features and versatile use cases make it a preferred choice for businesses seeking to enhance their automation capabilities. With the SR750, users can expect superior control, improved efficiency, and a significant return on investment, solidifying its position as a vital tool in the world of industrial automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

When it comes to reliability, performance, and advanced technology in the automation industry, GE has consistently delivered cutting-edge solutions. The GE SR750 stands as a testament to this legacy, offering unmatched capabilities tailored to meet the demands of modern industrial environments. This product description delves into the key technical features, usage scenarios, comparisons with other models, and highlights related models, showcasing why the GE SR750 is an essential addition to any automation setup.

Key Technical Features

The GE SR750 is engineered with precision, featuring a robust design that enhances its operational efficiency. Key technical features include:

1. **High Processing Power**: The SR750 is equipped with a powerful processor that ensures rapid data handling and real-time analytics. Its advanced architecture allows it to manage complex automation tasks without compromising speed or accuracy.

2. **Modular Design**: The SR750 embraces a modular design, allowing for easy scalability. This feature enables users to customize their systems according to specific operational requirements, enhancing flexibility in various applications.

3. **Integrated Communication Protocols**: The device supports multiple communication protocols, including Ethernet/IP and Modbus TCP, facilitating seamless integration with a wide range of devices and systems. This interoperability is crucial for modern industrial environments where diverse equipment must work together harmoniously.

4. **Enhanced Safety Features**: Safety is paramount in industrial settings. The GE SR750 incorporates advanced safety features, including built-in redundancy and fail-safe mechanisms, ensuring uninterrupted operation and minimal downtime.

5. **User-Friendly Interface**: The SR750 boasts an intuitive user interface that simplifies configuration and monitoring. Users can easily navigate through settings, access data, and make adjustments in real time, enhancing overall operational efficiency.

6. **Rugged Durability**: Designed for harsh environments, the SR750 withstands extreme temperatures, vibrations, and dust, making it suitable for a variety of industrial applications. Its rugged construction ensures longevity and reliability, even in challenging conditions.

Usage Scenarios

The GE SR750 is versatile and adaptable to numerous industrial applications, making it ideal for a wide range of sectors, including:

1. **Manufacturing**: In manufacturing plants, the SR750 can manage production lines, monitor machinery, and ensure optimal performance, contributing to increased productivity and reduced operational costs.

2. **Oil and Gas**: The SR750 is well-suited for the oil and gas industry, where it can oversee drilling operations, manage equipment, and ensure compliance with safety regulations, all while maintaining real-time data analytics.

3. **Water Treatment**: In water treatment facilities, the SR750 can control various processes, from filtration to chemical dosing, ensuring that water quality meets regulatory standards while optimizing resource usage.

4. **Transportation**: The device can be employed in transportation systems to manage traffic signals, monitor vehicle flow, and enhance public safety through efficient control mechanisms.

5. **Utilities**: The SR750 can play a critical role in utility management, monitoring energy consumption, controlling distribution networks, and maintaining system integrity across vast infrastructures.

Comparison with Other Models

When comparing the GE SR750 with other models within the GE automation products lineup, several distinctions emerge. For instance, while the GE IS200TBCIH1BBC and GE IS220PPROS1B are robust options for specific applications, the SR750 surpasses them in processing power and modularity, making it more suitable for complex and scalable environments.

Similarly, models like the GE IC697MDL250 and GE DS200SDCCG1AGD may offer specialized features, but the SR750's comprehensive integration capabilities and enhanced safety mechanisms provide a competitive edge. Its versatility sets it apart from the GE IS215UCVEH2AB and GE 369-HI-0-M-0-0-0, which are tailored for niche applications.

Moreover, while the GE IC693CPU374 and GE IC698CMX016 are reliable options, the SR750's strengths in communication protocols and user interface design elevate it to a higher tier of automation products, catering to the evolving needs of industries.

Related Models

For those exploring the capabilities of the GE SR750, several related models are noteworthy:

1. **GE IS200TBCIH1BBC**: A solid choice for control applications, offering reliable performance.

2. **GE IS220PPROS1B**: Known for its advanced processing capabilities in specific automation tasks.

3. **GE CT7P70500470CW24**: A versatile model ideal for various industrial applications.

4. **GE EVMECNTM13**: Tailored for energy management solutions.

5. **GE IS220PAICH2A**: Focused on process automation with a robust feature set.

6. **GE IC697MDL250**: A reliable option for discrete input/output tasks.

7. **GE DS200CTBAG1ADD**: Suited for control systems with a focus on diagnostics.

8. **GE IS200EPSMG2ADC**: Designed for enhanced safety and operational reliability in critical systems.

9. **GE IC670MDL740J**: Offers high-performance control in rugged environments.

10. **GE IS230SNIDH1A**: Ideal for advanced networking applications in automation.

Conclusion

The GE SR750 is a groundbreaking addition to the suite of GE automation products, offering unparalleled performance, modularity, and reliability for diverse industrial applications. Its advanced features and versatile use cases make it a preferred choice for businesses seeking to enhance their automation capabilities. With the SR750, users can expect superior control, improved efficiency, and a significant return on investment, solidifying its position as a vital tool in the world of industrial automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.