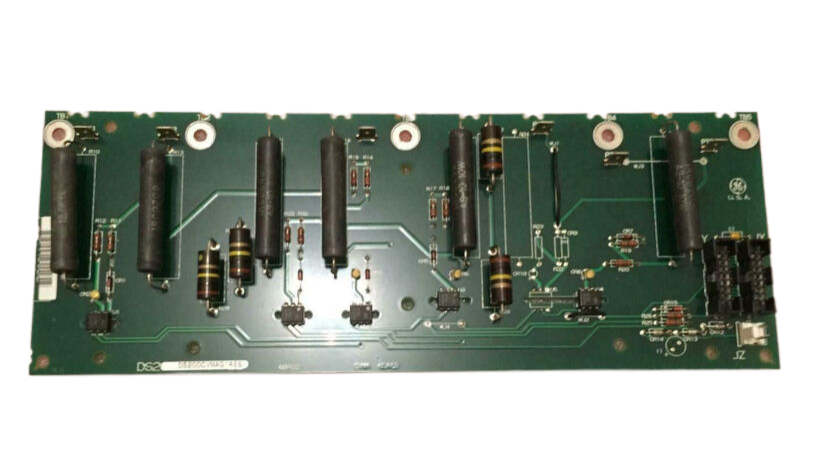

GE Fanuc DS200LDCCH1 Circuit Board Advanced Control Module for Industrial Automation

Introducing the GE Fanuc Model, a standout in the realm of GE automation products, designed to enhance operational efficiency and reliability across various industrial applications. This innovative model combines cutting-edge technology with user-friendly features, making it an essential component for businesses seeking to optimize their processes.

Key Technical Features

The GE Fanuc Model boasts an array of technical features that set it apart in the automation landscape. At its core, it incorporates advanced processing capabilities that allow for quick and efficient data handling. The model is equipped with a robust microprocessor that ensures high-speed computations and seamless integration with existing systems.

One of the standout features is its modular design, which allows for easy scalability. Whether you are expanding your operation or upgrading existing equipment, the GE Fanuc Model can be easily adapted to meet your growing needs. With support for a wide range of I/O modules, including digital and analog inputs and outputs, this model provides the flexibility required for diverse applications.

The GE Fanuc Model also includes built-in diagnostics and monitoring capabilities, which enable users to identify potential issues before they escalate. This proactive approach not only enhances the reliability of operations but also minimizes downtime, resulting in significant cost savings. Additionally, the model supports multiple communication protocols, ensuring compatibility with various devices and facilitating seamless data exchange.

Usage Scenarios

The versatility of the GE Fanuc Model makes it suitable for numerous applications across different industries. In manufacturing environments, it can be deployed for process control, allowing for real-time monitoring and adjustments to ensure optimal performance. Industries such as oil and gas, food and beverage, and pharmaceuticals can benefit from its precise control capabilities and reliability.

In the energy sector, the GE Fanuc Model plays a crucial role in power monitoring and grid management. Its ability to handle large volumes of data and provide real-time feedback is vital for maintaining the stability and efficiency of energy systems. Furthermore, in the transportation sector, this model can streamline operations by facilitating automated control systems for railways, airports, and logistics hubs.

Moreover, the GE Fanuc Model is ideal for building automation, where it can manage HVAC systems, lighting controls, and security systems to improve energy efficiency and occupant comfort. Its adaptability makes it a preferred choice for system integrators and engineers looking to implement sophisticated automation solutions.

Comparison with Other Models

When comparing the GE Fanuc Model to other models within the GE brand, such as the GE SR750 and GE IS200DSPXH2DBD, it becomes evident that the GE Fanuc Model stands out in terms of processing power and modularity. While the GE SR750 is excellent for specific applications, it may lack the scalability offered by the GE Fanuc Model, making it less suitable for rapidly changing industrial environments.

On the other hand, models like the GE IC693APU301 and GE IS200EDFFH1ABA provide reliable performance but may not deliver the same level of integration capabilities as the GE Fanuc Model. This makes the GE Fanuc Model an attractive option for businesses looking for a comprehensive solution that can evolve with their needs.

Additionally, the GE DS200DDTBG2A and GE IC660BBA020 provide robust performance in their respective domains but may not match the versatility and adaptability of the GE Fanuc Model. With its ability to support various communication protocols and I/O modules, the GE Fanuc Model is engineered for a broader scope of applications compared to these other models.

Reference to Related Models

To further illustrate the versatility and reliability of the GE Fanuc Model, here are ten related models that complement its capabilities:

1. GE SR750 – A robust model suitable for specific automation tasks.

2. GE IC697MDL740 – Known for its reliability in industrial environments.

3. GE IS200DSFCG1AEB – Offers excellent performance in process control.

4. GE IC660BBA020 – A dependable option for complex control systems.

5. GE IS200DSPXH2DBD – Ideal for digital signal processing applications.

6. GE IS220PPDAH1A – A module designed for precise process automation.

7. GE IS200VTURH1BAC – Focused on turbine control applications.

8. GE IC200CPU005 – A compact PLC suitable for smaller applications.

9. GE IC695CPE310-ABAH – Known for its high-speed processing capabilities.

10. GE IC694PWR331 – A reliable power supply module for GE automation products.

These models, alongside the GE Fanuc Model, represent the breadth and depth of GE's offerings in automation technology, ensuring that businesses can find the right solution for their specific needs.

In conclusion, the GE Fanuc Model emerges as a leader in the realm of GE automation products, marked by its innovative features, versatility, and reliability. Its modularity and advanced processing capabilities make it an ideal choice for a wide range of industrial applications. Businesses seeking to enhance their operational efficiency and embrace automation technology should consider the GE Fanuc Model as a vital component in achieving their goals. With its ability to integrate seamlessly with existing systems and adapt to evolving needs, the GE Fanuc Model is not just a product; it is a strategic investment for the future of industrial automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE Fanuc Model boasts an array of technical features that set it apart in the automation landscape. At its core, it incorporates advanced processing capabilities that allow for quick and efficient data handling. The model is equipped with a robust microprocessor that ensures high-speed computations and seamless integration with existing systems.

One of the standout features is its modular design, which allows for easy scalability. Whether you are expanding your operation or upgrading existing equipment, the GE Fanuc Model can be easily adapted to meet your growing needs. With support for a wide range of I/O modules, including digital and analog inputs and outputs, this model provides the flexibility required for diverse applications.

The GE Fanuc Model also includes built-in diagnostics and monitoring capabilities, which enable users to identify potential issues before they escalate. This proactive approach not only enhances the reliability of operations but also minimizes downtime, resulting in significant cost savings. Additionally, the model supports multiple communication protocols, ensuring compatibility with various devices and facilitating seamless data exchange.

Usage Scenarios

The versatility of the GE Fanuc Model makes it suitable for numerous applications across different industries. In manufacturing environments, it can be deployed for process control, allowing for real-time monitoring and adjustments to ensure optimal performance. Industries such as oil and gas, food and beverage, and pharmaceuticals can benefit from its precise control capabilities and reliability.

In the energy sector, the GE Fanuc Model plays a crucial role in power monitoring and grid management. Its ability to handle large volumes of data and provide real-time feedback is vital for maintaining the stability and efficiency of energy systems. Furthermore, in the transportation sector, this model can streamline operations by facilitating automated control systems for railways, airports, and logistics hubs.

Moreover, the GE Fanuc Model is ideal for building automation, where it can manage HVAC systems, lighting controls, and security systems to improve energy efficiency and occupant comfort. Its adaptability makes it a preferred choice for system integrators and engineers looking to implement sophisticated automation solutions.

Comparison with Other Models

When comparing the GE Fanuc Model to other models within the GE brand, such as the GE SR750 and GE IS200DSPXH2DBD, it becomes evident that the GE Fanuc Model stands out in terms of processing power and modularity. While the GE SR750 is excellent for specific applications, it may lack the scalability offered by the GE Fanuc Model, making it less suitable for rapidly changing industrial environments.

On the other hand, models like the GE IC693APU301 and GE IS200EDFFH1ABA provide reliable performance but may not deliver the same level of integration capabilities as the GE Fanuc Model. This makes the GE Fanuc Model an attractive option for businesses looking for a comprehensive solution that can evolve with their needs.

Additionally, the GE DS200DDTBG2A and GE IC660BBA020 provide robust performance in their respective domains but may not match the versatility and adaptability of the GE Fanuc Model. With its ability to support various communication protocols and I/O modules, the GE Fanuc Model is engineered for a broader scope of applications compared to these other models.

Reference to Related Models

To further illustrate the versatility and reliability of the GE Fanuc Model, here are ten related models that complement its capabilities:

1. GE SR750 – A robust model suitable for specific automation tasks.

2. GE IC697MDL740 – Known for its reliability in industrial environments.

3. GE IS200DSFCG1AEB – Offers excellent performance in process control.

4. GE IC660BBA020 – A dependable option for complex control systems.

5. GE IS200DSPXH2DBD – Ideal for digital signal processing applications.

6. GE IS220PPDAH1A – A module designed for precise process automation.

7. GE IS200VTURH1BAC – Focused on turbine control applications.

8. GE IC200CPU005 – A compact PLC suitable for smaller applications.

9. GE IC695CPE310-ABAH – Known for its high-speed processing capabilities.

10. GE IC694PWR331 – A reliable power supply module for GE automation products.

These models, alongside the GE Fanuc Model, represent the breadth and depth of GE's offerings in automation technology, ensuring that businesses can find the right solution for their specific needs.

In conclusion, the GE Fanuc Model emerges as a leader in the realm of GE automation products, marked by its innovative features, versatility, and reliability. Its modularity and advanced processing capabilities make it an ideal choice for a wide range of industrial applications. Businesses seeking to enhance their operational efficiency and embrace automation technology should consider the GE Fanuc Model as a vital component in achieving their goals. With its ability to integrate seamlessly with existing systems and adapt to evolving needs, the GE Fanuc Model is not just a product; it is a strategic investment for the future of industrial automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.