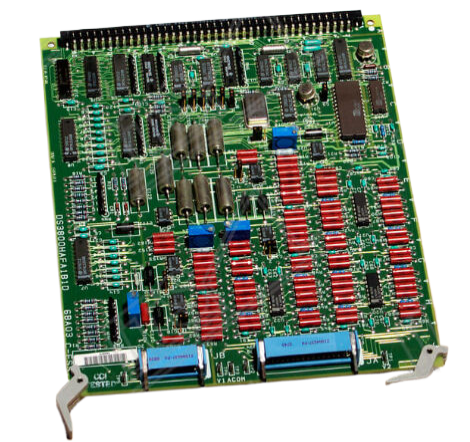

GE Fanuc DS200DTBDG1ABB Terminal Relay Board

Introducing the GE Fanuc Model: A Leader in Automation Technology

In the ever-evolving world of industrial automation, GE Fanuc stands as a beacon of innovation, reliability, and efficiency. The GE Fanuc model is designed to meet the rigorous demands of modern manufacturing environments, providing a powerful solution for automation needs. With a focus on performance, flexibility, and ease of use, this model is an ideal choice for businesses looking to enhance their operational capabilities.

Key Technical Features

The GE Fanuc model boasts an impressive array of technical features tailored for high-performance automation. One of its standout characteristics is its robust processing power, which is essential for handling complex control tasks seamlessly. The model is equipped with advanced communication protocols, ensuring compatibility with various industrial networks, such as Ethernet/IP, Modbus, and Profibus. This versatility allows for seamless integration into existing systems, enhancing overall operational efficiency.

Another key feature is its modular design, which enables scalability and customization. Users can easily add or replace components, making it possible to tailor the system to specific application requirements. Additionally, the GE Fanuc model supports a wide range of I/O modules, allowing for the connection of various sensors, actuators, and other devices critical for automation.

The model is also designed for high reliability, with built-in diagnostic capabilities that facilitate real-time monitoring of system performance. This proactive approach helps to identify potential issues before they escalate, minimizing downtime and maintenance costs. Furthermore, the GE Fanuc model is engineered to operate in harsh industrial environments, with enhanced protection against dust, moisture, and temperature fluctuations.

Usage Scenarios

The versatility of the GE Fanuc model makes it suitable for various applications across multiple industries. In manufacturing, it can be employed for assembly line automation, where precision and speed are paramount. The model's ability to integrate with robotic systems allows for seamless operation, enhancing productivity and reducing labor costs.

In the process industry, the GE Fanuc model is ideal for monitoring and controlling complex processes, such as chemical production or oil refining. Its advanced control algorithms ensure optimal performance, maintaining product quality while minimizing waste and energy consumption.

Moreover, the GE Fanuc model is an excellent choice for building automation systems, where it can manage heating, ventilation, and air conditioning (HVAC) systems, lighting, and security. Its flexibility and scalability make it easy to adapt to changing requirements, ensuring that buildings operate efficiently and sustainably.

Comparison with Other Models

When compared to other models within the GE automation products lineup, the GE Fanuc model stands out for its combination of performance and adaptability. For instance, while the GE IC697MDL740 is known for its reliability in discrete control applications, the GE Fanuc model offers more advanced features for complex automation tasks.

In contrast to the GE IS200DSPXH2DBD, which is geared towards specialized applications, the GE Fanuc model provides a broader range of functionalities, making it a more versatile choice for businesses seeking a comprehensive automation solution. Additionally, the GE IC660BBA020 and GE DS200DDTBG2A models may excel in specific areas, but they lack the scalability and modularity that define the GE Fanuc model.

For users considering high-performance needs, the GE SR750 delivers exceptional processing capabilities, yet the GE Fanuc model offers a more balanced approach, delivering robust performance while maintaining ease of use and integration.

Reference Related Models

When exploring the GE Fanuc model, it’s worth noting several related models that complement its capabilities within the GE automation products ecosystem. These include:

1. GE IS200EDFFH1ABA – Ideal for advanced control applications.

2. GE IC200CPU005 – A versatile controller for various automation tasks.

3. GE IS220PPDAH1A – Focused on process control with high reliability.

4. GE IC694PWR331 – A power supply model designed for robust performance.

5. GE IC693ACC302 – An accessory module for enhanced connectivity.

6. GE DS200SIOCG1A – A signal input/output controller for seamless communication.

7. GE IS200TRPGH1BDE – A control module for advanced process automation.

8. GE IC695CPE310-ABAH – A powerful control platform for complex applications.

9. GE IS200JPDMG1ADC – A digital signal processor for precise control.

10. GE DS3800XPER – A high-performance module for specialized tasks.

Each of these models provides unique features and benefits that can enhance the overall automation strategy when used in conjunction with the GE Fanuc model.

Conclusion

In conclusion, the GE Fanuc model represents the forefront of automation technology, combining advanced features, versatility, and reliability into one comprehensive solution. With its robust processing power, modular design, and adaptability to various applications, it is a top choice for businesses looking to improve their automation systems. Whether in manufacturing, process control, or building automation, the GE Fanuc model stands ready to meet the challenges of today's industrial landscape, ensuring that your operations run smoothly and efficiently. Embrace the future of automation with the GE Fanuc model and experience the difference that cutting-edge technology can make for your business.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the ever-evolving world of industrial automation, GE Fanuc stands as a beacon of innovation, reliability, and efficiency. The GE Fanuc model is designed to meet the rigorous demands of modern manufacturing environments, providing a powerful solution for automation needs. With a focus on performance, flexibility, and ease of use, this model is an ideal choice for businesses looking to enhance their operational capabilities.

Key Technical Features

The GE Fanuc model boasts an impressive array of technical features tailored for high-performance automation. One of its standout characteristics is its robust processing power, which is essential for handling complex control tasks seamlessly. The model is equipped with advanced communication protocols, ensuring compatibility with various industrial networks, such as Ethernet/IP, Modbus, and Profibus. This versatility allows for seamless integration into existing systems, enhancing overall operational efficiency.

Another key feature is its modular design, which enables scalability and customization. Users can easily add or replace components, making it possible to tailor the system to specific application requirements. Additionally, the GE Fanuc model supports a wide range of I/O modules, allowing for the connection of various sensors, actuators, and other devices critical for automation.

The model is also designed for high reliability, with built-in diagnostic capabilities that facilitate real-time monitoring of system performance. This proactive approach helps to identify potential issues before they escalate, minimizing downtime and maintenance costs. Furthermore, the GE Fanuc model is engineered to operate in harsh industrial environments, with enhanced protection against dust, moisture, and temperature fluctuations.

Usage Scenarios

The versatility of the GE Fanuc model makes it suitable for various applications across multiple industries. In manufacturing, it can be employed for assembly line automation, where precision and speed are paramount. The model's ability to integrate with robotic systems allows for seamless operation, enhancing productivity and reducing labor costs.

In the process industry, the GE Fanuc model is ideal for monitoring and controlling complex processes, such as chemical production or oil refining. Its advanced control algorithms ensure optimal performance, maintaining product quality while minimizing waste and energy consumption.

Moreover, the GE Fanuc model is an excellent choice for building automation systems, where it can manage heating, ventilation, and air conditioning (HVAC) systems, lighting, and security. Its flexibility and scalability make it easy to adapt to changing requirements, ensuring that buildings operate efficiently and sustainably.

Comparison with Other Models

When compared to other models within the GE automation products lineup, the GE Fanuc model stands out for its combination of performance and adaptability. For instance, while the GE IC697MDL740 is known for its reliability in discrete control applications, the GE Fanuc model offers more advanced features for complex automation tasks.

In contrast to the GE IS200DSPXH2DBD, which is geared towards specialized applications, the GE Fanuc model provides a broader range of functionalities, making it a more versatile choice for businesses seeking a comprehensive automation solution. Additionally, the GE IC660BBA020 and GE DS200DDTBG2A models may excel in specific areas, but they lack the scalability and modularity that define the GE Fanuc model.

For users considering high-performance needs, the GE SR750 delivers exceptional processing capabilities, yet the GE Fanuc model offers a more balanced approach, delivering robust performance while maintaining ease of use and integration.

Reference Related Models

When exploring the GE Fanuc model, it’s worth noting several related models that complement its capabilities within the GE automation products ecosystem. These include:

1. GE IS200EDFFH1ABA – Ideal for advanced control applications.

2. GE IC200CPU005 – A versatile controller for various automation tasks.

3. GE IS220PPDAH1A – Focused on process control with high reliability.

4. GE IC694PWR331 – A power supply model designed for robust performance.

5. GE IC693ACC302 – An accessory module for enhanced connectivity.

6. GE DS200SIOCG1A – A signal input/output controller for seamless communication.

7. GE IS200TRPGH1BDE – A control module for advanced process automation.

8. GE IC695CPE310-ABAH – A powerful control platform for complex applications.

9. GE IS200JPDMG1ADC – A digital signal processor for precise control.

10. GE DS3800XPER – A high-performance module for specialized tasks.

Each of these models provides unique features and benefits that can enhance the overall automation strategy when used in conjunction with the GE Fanuc model.

Conclusion

In conclusion, the GE Fanuc model represents the forefront of automation technology, combining advanced features, versatility, and reliability into one comprehensive solution. With its robust processing power, modular design, and adaptability to various applications, it is a top choice for businesses looking to improve their automation systems. Whether in manufacturing, process control, or building automation, the GE Fanuc model stands ready to meet the challenges of today's industrial landscape, ensuring that your operations run smoothly and efficiently. Embrace the future of automation with the GE Fanuc model and experience the difference that cutting-edge technology can make for your business.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.