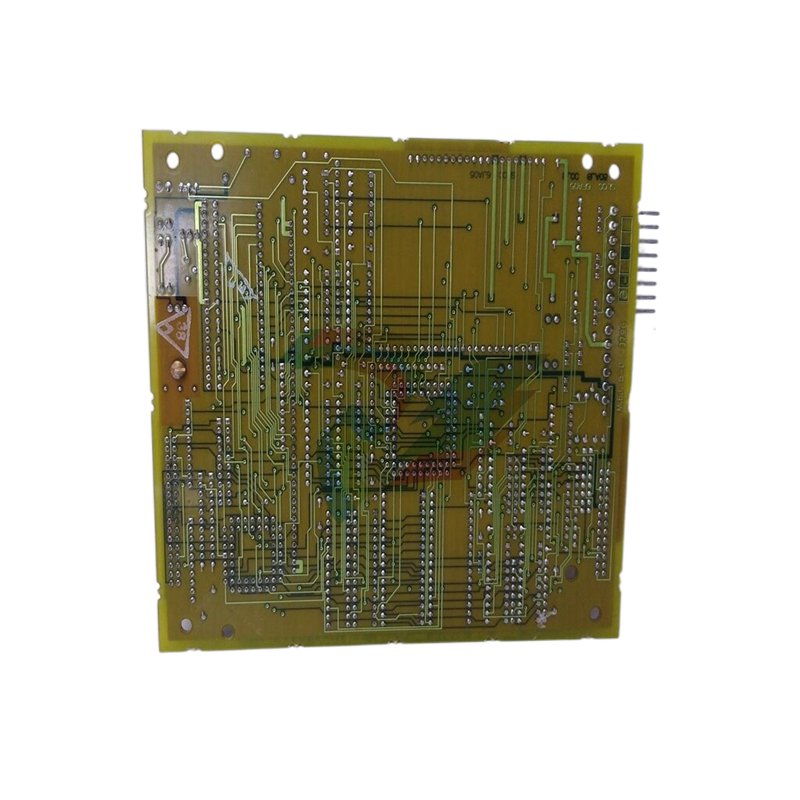

GE Fanuc IC693MDL742 PAC Systems RX3i Control Module

Introducing the GE Fanuc, a robust and versatile solution designed to meet the evolving demands of modern automation systems. As a leader in the industry, GE Fanuc combines advanced technology with unparalleled reliability, making it an ideal choice for a wide range of applications.

**Key Technical Features**

The GE Fanuc boasts an impressive array of technical features that set it apart from other models in the GE lineup. With high-performance processing capabilities, the GE Fanuc ensures efficient operation for complex industrial tasks. The module is equipped with advanced input/output (I/O) configurations, facilitating seamless integration into existing systems.

One of the standout features of the GE Fanuc is its compatibility with various communication protocols, enabling users to connect and communicate effortlessly across different platforms. This flexibility is crucial in today’s interconnected manufacturing environments, where devices need to exchange data in real time.

In addition, the GE Fanuc is designed for durability, featuring a rugged casing that can withstand harsh industrial conditions. The device operates reliably in extreme temperatures and high-vibration settings, making it suitable for diverse environments, from manufacturing floors to outdoor installations.

Furthermore, the GE Fanuc supports extensive programmability, allowing users to customize operations according to their specific requirements. The intuitive user interface and comprehensive software support simplify programming, making it accessible to both seasoned professionals and newcomers to automation.

**Usage Scenarios**

The GE Fanuc finds application across various industries, including manufacturing, energy, transportation, and process control. In a manufacturing setting, it can be used to automate assembly lines, monitor production processes, and manage quality control systems. The high-speed processing capabilities allow for real-time data analysis, enabling manufacturers to optimize operations and reduce downtime.

In energy production, the GE Fanuc can monitor and control equipment in power plants, ensuring efficient energy generation and distribution. Its robust features make it ideal for managing turbine operations, grid connections, and renewable energy systems.

Transportation systems also benefit from the GE Fanuc’s capabilities. It can be utilized to manage traffic signals, control public transport systems, and enhance logistics operations. By implementing the GE Fanuc, transportation authorities can improve traffic flow, enhance safety, and reduce operational costs.

In process control applications, the GE Fanuc excels in managing chemical processing, food and beverage production, and water treatment facilities. The device’s precise control and monitoring capabilities ensure high-quality production and compliance with industry standards.

**Comparison with Other Models**

When comparing the GE Fanuc to other models within the GE automation products family, it stands out for its versatility and adaptability. For instance, while the GE SR750 is known for its high-speed processing, the GE Fanuc offers broader compatibility with various I/O modules, making it more suitable for diverse applications.

Similarly, the GE IS200DSPXH2DBD is designed for specialized tasks, but it lacks the extensive communication protocol support that the GE Fanuc provides. This flexibility makes the GE Fanuc a preferred choice for organizations looking to streamline their operations across different systems.

While models like the GE IC695CPE310-ABAH and GE IS200EDFFH1ABA deliver reliable performance, they may not match the GE Fanuc’s robust programmability features. The ease of customization offered by the GE Fanuc gives it an edge in environments where tailored solutions are essential.

Moreover, compared to models such as the GE IC693APU301 and GE IS200VTURH1BAC, the GE Fanuc offers an enhanced user interface that simplifies programming and operation, making it more accessible to a broader range of users.

**Related Models**

The GE Fanuc is part of a comprehensive suite of GE automation products designed to cater to diverse industrial needs. Here are ten related models that complement the capabilities of the GE Fanuc:

1. GE SR750 – Known for high-speed processing and data handling.

2. GE IC697MDL740 – Offers robust I/O capabilities for complex systems.

3. GE IS200DSFCG1AEB – A specialized model for specific control tasks.

4. GE IC660BBA020 – Focuses on reliable communication in automation.

5. GE DS200DDTBG2A – Designed for dynamic process control.

6. GE IS200DSPXH2DBD – Supports customized automation solutions.

7. GE IS220PPDAH1A – Offers advanced process control features.

8. GE IC200CPU005 – A compact solution for small-scale automation.

9. GE IC695LRE001B – Provides enhanced reliability for critical operations.

10. GE IS200JPDMG1ADC – Ideal for managing data acquisition and communication.

**Conclusion**

In conclusion, the GE Fanuc represents a significant advancement in the realm of automation products. With its robust technical features, versatile usage scenarios, and superior adaptability compared to other models, it is the go-to solution for businesses aiming to enhance their operational efficiency. Whether in manufacturing, energy, transportation, or process control, the GE Fanuc delivers reliable performance and unmatched flexibility. Explore the possibilities with GE automation products and discover how the GE Fanuc can transform your operations today.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The GE Fanuc boasts an impressive array of technical features that set it apart from other models in the GE lineup. With high-performance processing capabilities, the GE Fanuc ensures efficient operation for complex industrial tasks. The module is equipped with advanced input/output (I/O) configurations, facilitating seamless integration into existing systems.

One of the standout features of the GE Fanuc is its compatibility with various communication protocols, enabling users to connect and communicate effortlessly across different platforms. This flexibility is crucial in today’s interconnected manufacturing environments, where devices need to exchange data in real time.

In addition, the GE Fanuc is designed for durability, featuring a rugged casing that can withstand harsh industrial conditions. The device operates reliably in extreme temperatures and high-vibration settings, making it suitable for diverse environments, from manufacturing floors to outdoor installations.

Furthermore, the GE Fanuc supports extensive programmability, allowing users to customize operations according to their specific requirements. The intuitive user interface and comprehensive software support simplify programming, making it accessible to both seasoned professionals and newcomers to automation.

**Usage Scenarios**

The GE Fanuc finds application across various industries, including manufacturing, energy, transportation, and process control. In a manufacturing setting, it can be used to automate assembly lines, monitor production processes, and manage quality control systems. The high-speed processing capabilities allow for real-time data analysis, enabling manufacturers to optimize operations and reduce downtime.

In energy production, the GE Fanuc can monitor and control equipment in power plants, ensuring efficient energy generation and distribution. Its robust features make it ideal for managing turbine operations, grid connections, and renewable energy systems.

Transportation systems also benefit from the GE Fanuc’s capabilities. It can be utilized to manage traffic signals, control public transport systems, and enhance logistics operations. By implementing the GE Fanuc, transportation authorities can improve traffic flow, enhance safety, and reduce operational costs.

In process control applications, the GE Fanuc excels in managing chemical processing, food and beverage production, and water treatment facilities. The device’s precise control and monitoring capabilities ensure high-quality production and compliance with industry standards.

**Comparison with Other Models**

When comparing the GE Fanuc to other models within the GE automation products family, it stands out for its versatility and adaptability. For instance, while the GE SR750 is known for its high-speed processing, the GE Fanuc offers broader compatibility with various I/O modules, making it more suitable for diverse applications.

Similarly, the GE IS200DSPXH2DBD is designed for specialized tasks, but it lacks the extensive communication protocol support that the GE Fanuc provides. This flexibility makes the GE Fanuc a preferred choice for organizations looking to streamline their operations across different systems.

While models like the GE IC695CPE310-ABAH and GE IS200EDFFH1ABA deliver reliable performance, they may not match the GE Fanuc’s robust programmability features. The ease of customization offered by the GE Fanuc gives it an edge in environments where tailored solutions are essential.

Moreover, compared to models such as the GE IC693APU301 and GE IS200VTURH1BAC, the GE Fanuc offers an enhanced user interface that simplifies programming and operation, making it more accessible to a broader range of users.

**Related Models**

The GE Fanuc is part of a comprehensive suite of GE automation products designed to cater to diverse industrial needs. Here are ten related models that complement the capabilities of the GE Fanuc:

1. GE SR750 – Known for high-speed processing and data handling.

2. GE IC697MDL740 – Offers robust I/O capabilities for complex systems.

3. GE IS200DSFCG1AEB – A specialized model for specific control tasks.

4. GE IC660BBA020 – Focuses on reliable communication in automation.

5. GE DS200DDTBG2A – Designed for dynamic process control.

6. GE IS200DSPXH2DBD – Supports customized automation solutions.

7. GE IS220PPDAH1A – Offers advanced process control features.

8. GE IC200CPU005 – A compact solution for small-scale automation.

9. GE IC695LRE001B – Provides enhanced reliability for critical operations.

10. GE IS200JPDMG1ADC – Ideal for managing data acquisition and communication.

**Conclusion**

In conclusion, the GE Fanuc represents a significant advancement in the realm of automation products. With its robust technical features, versatile usage scenarios, and superior adaptability compared to other models, it is the go-to solution for businesses aiming to enhance their operational efficiency. Whether in manufacturing, energy, transportation, or process control, the GE Fanuc delivers reliable performance and unmatched flexibility. Explore the possibilities with GE automation products and discover how the GE Fanuc can transform your operations today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.