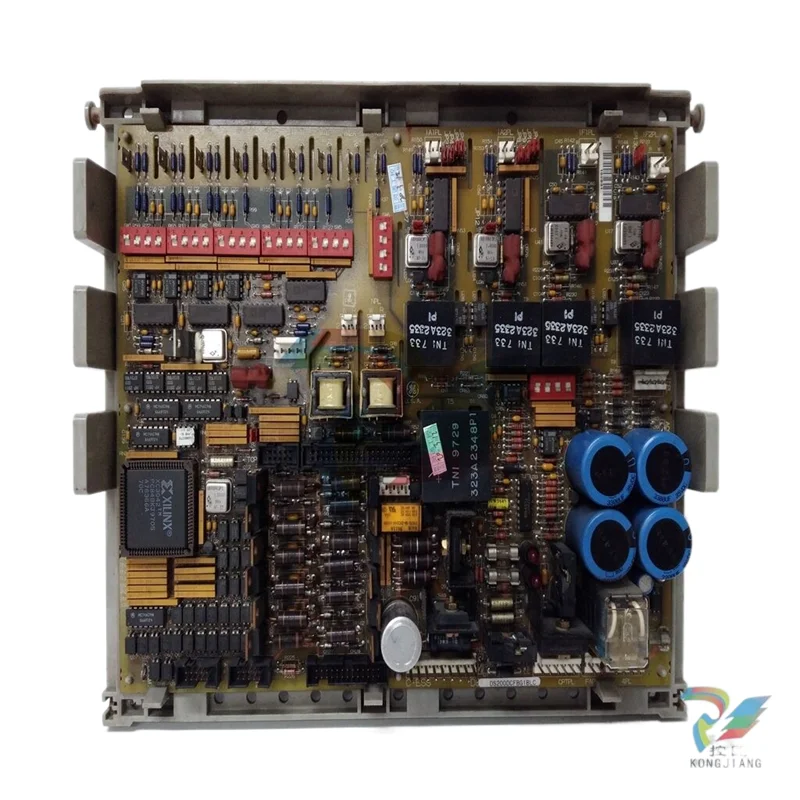

GE Fanuc A16B-3200-0810 R-30iB PLUS MAIN PCB Advanced Control Solution for Industrial Automation

Introducing the GE Fanuc, a cutting-edge solution in the realm of industrial automation that enhances efficiency, reliability, and performance across various applications. Renowned for its precision and advanced features, this model stands out in GE's extensive lineup of automation products, making it an ideal choice for industries ranging from manufacturing to energy management.

Key Technical Features

The GE Fanuc is engineered with a robust set of technical specifications designed for high-performance applications. Key features include:

1. **Advanced Processing Power**: The GE Fanuc model boasts a powerful processor that ensures rapid data processing and real-time control, making it suitable for complex automation tasks.

2. **Enhanced Connectivity**: This model supports multiple communication protocols, including Ethernet, Serial, and Fieldbus, allowing seamless integration within existing systems and enhancing interoperability with other GE automation products.

3. **Scalability**: The GE Fanuc is designed for scalability, enabling it to adapt to varying workload demands. Its modular design allows users to easily add or remove components based on operational requirements.

4. **User-Friendly Interface**: Featuring an intuitive graphical user interface (GUI), the GE Fanuc simplifies programming and operation, reducing the learning curve for new users and increasing overall productivity.

5. **Robust Environmental Tolerance**: Built to withstand harsh industrial environments, the GE Fanuc can operate in extreme temperatures, humidity, and dust conditions, ensuring longevity and reliability.

6. **Comprehensive Diagnostics**: With built-in diagnostic tools and self-monitoring capabilities, the GE Fanuc provides operators with valuable insights into system performance, aiding in timely maintenance and reducing downtime.

Usage Scenarios

The versatility of the GE Fanuc makes it suitable for a wide range of applications:

1. **Manufacturing Automation**: In production lines, the GE Fanuc can control robotic arms, conveyors, and assembly processes, ensuring precision and efficiency in manufacturing.

2. **Energy Management**: The model is adept at monitoring and controlling energy distribution systems, optimizing energy use, and enhancing overall system efficiency.

3. **Process Control**: Industries such as chemical, food processing, and pharmaceuticals benefit from the GE Fanuc’s ability to monitor and regulate complex processes, ensuring quality and consistency.

4. **Building Automation**: The GE Fanuc can be employed in smart building systems, managing lighting, HVAC, and security systems to improve energy efficiency and occupant comfort.

5. **Remote Monitoring**: With its enhanced connectivity features, the GE Fanuc enables remote monitoring and control of systems, allowing operators to manage operations from anywhere, thus increasing flexibility.

Comparison with Other Models

When compared to other models within the GE family, such as the GE SR750 and GE IC697MDL740, the GE Fanuc distinguishes itself with its superior processing capability and comprehensive connectivity options. While the SR750 is more suited for standalone applications, the GE Fanuc excels in integrated environments.

In contrast, models like the GE IS200EDFFH1ABA and GE IS200DSPXH2DBD focus on specific industrial needs, such as drive control and signal processing. The GE Fanuc, however, offers a broader scope, making it a versatile choice across multiple sectors. Additionally, when compared to the GE IC660BBA020, known for its specialized applications, the GE Fanuc delivers a more comprehensive suite of features suitable for diverse operational requirements.

Related Models

To provide further context, here are ten related models within the GE product range that complement the GE Fanuc:

1. **GE SR750**: A highly reliable model focused on standalone applications.

2. **GE IC697MDL740**: Ideal for I/O control in process automation.

3. **GE IS200DSFCG1AEB**: Designed for motor control applications.

4. **GE IC660BBA020**: Known for its specialized communication capabilities.

5. **GE IS200DSPXH2DBD**: Focuses on digital signal processing.

6. **GE DS200DDTBG2A**: A component for drive control systems.

7. **GE IC693APU301**: Excellent for advanced programming needs.

8. **GE IS200EDFFH1ABA**: Tailored for efficient drive control.

9. **GE IC695CPE310-ABAH**: Known for its compact design and performance.

10. **GE IS200JPDMG1ADC**: Specializes in process control applications.

SEO Keywords

When discussing the GE Fanuc, it’s essential to highlight its significance in the realm of GE automation products. This model not only embodies the innovation and reliability that GE is known for but also reinforces the brand's commitment to advancing industrial automation technology.

In conclusion, the GE Fanuc stands as a premier choice for industries seeking a reliable, versatile, and high-performing automation solution. With its advanced features and adaptability, it is poised to meet the evolving demands of modern industrial operations, making it an indispensable asset in your automation toolkit. Whether you're in manufacturing, energy, or any sector requiring precise control and monitoring, the GE Fanuc is designed to elevate your operational capabilities to new heights.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE Fanuc is engineered with a robust set of technical specifications designed for high-performance applications. Key features include:

1. **Advanced Processing Power**: The GE Fanuc model boasts a powerful processor that ensures rapid data processing and real-time control, making it suitable for complex automation tasks.

2. **Enhanced Connectivity**: This model supports multiple communication protocols, including Ethernet, Serial, and Fieldbus, allowing seamless integration within existing systems and enhancing interoperability with other GE automation products.

3. **Scalability**: The GE Fanuc is designed for scalability, enabling it to adapt to varying workload demands. Its modular design allows users to easily add or remove components based on operational requirements.

4. **User-Friendly Interface**: Featuring an intuitive graphical user interface (GUI), the GE Fanuc simplifies programming and operation, reducing the learning curve for new users and increasing overall productivity.

5. **Robust Environmental Tolerance**: Built to withstand harsh industrial environments, the GE Fanuc can operate in extreme temperatures, humidity, and dust conditions, ensuring longevity and reliability.

6. **Comprehensive Diagnostics**: With built-in diagnostic tools and self-monitoring capabilities, the GE Fanuc provides operators with valuable insights into system performance, aiding in timely maintenance and reducing downtime.

Usage Scenarios

The versatility of the GE Fanuc makes it suitable for a wide range of applications:

1. **Manufacturing Automation**: In production lines, the GE Fanuc can control robotic arms, conveyors, and assembly processes, ensuring precision and efficiency in manufacturing.

2. **Energy Management**: The model is adept at monitoring and controlling energy distribution systems, optimizing energy use, and enhancing overall system efficiency.

3. **Process Control**: Industries such as chemical, food processing, and pharmaceuticals benefit from the GE Fanuc’s ability to monitor and regulate complex processes, ensuring quality and consistency.

4. **Building Automation**: The GE Fanuc can be employed in smart building systems, managing lighting, HVAC, and security systems to improve energy efficiency and occupant comfort.

5. **Remote Monitoring**: With its enhanced connectivity features, the GE Fanuc enables remote monitoring and control of systems, allowing operators to manage operations from anywhere, thus increasing flexibility.

Comparison with Other Models

When compared to other models within the GE family, such as the GE SR750 and GE IC697MDL740, the GE Fanuc distinguishes itself with its superior processing capability and comprehensive connectivity options. While the SR750 is more suited for standalone applications, the GE Fanuc excels in integrated environments.

In contrast, models like the GE IS200EDFFH1ABA and GE IS200DSPXH2DBD focus on specific industrial needs, such as drive control and signal processing. The GE Fanuc, however, offers a broader scope, making it a versatile choice across multiple sectors. Additionally, when compared to the GE IC660BBA020, known for its specialized applications, the GE Fanuc delivers a more comprehensive suite of features suitable for diverse operational requirements.

Related Models

To provide further context, here are ten related models within the GE product range that complement the GE Fanuc:

1. **GE SR750**: A highly reliable model focused on standalone applications.

2. **GE IC697MDL740**: Ideal for I/O control in process automation.

3. **GE IS200DSFCG1AEB**: Designed for motor control applications.

4. **GE IC660BBA020**: Known for its specialized communication capabilities.

5. **GE IS200DSPXH2DBD**: Focuses on digital signal processing.

6. **GE DS200DDTBG2A**: A component for drive control systems.

7. **GE IC693APU301**: Excellent for advanced programming needs.

8. **GE IS200EDFFH1ABA**: Tailored for efficient drive control.

9. **GE IC695CPE310-ABAH**: Known for its compact design and performance.

10. **GE IS200JPDMG1ADC**: Specializes in process control applications.

SEO Keywords

When discussing the GE Fanuc, it’s essential to highlight its significance in the realm of GE automation products. This model not only embodies the innovation and reliability that GE is known for but also reinforces the brand's commitment to advancing industrial automation technology.

In conclusion, the GE Fanuc stands as a premier choice for industries seeking a reliable, versatile, and high-performing automation solution. With its advanced features and adaptability, it is poised to meet the evolving demands of modern industrial operations, making it an indispensable asset in your automation toolkit. Whether you're in manufacturing, energy, or any sector requiring precise control and monitoring, the GE Fanuc is designed to elevate your operational capabilities to new heights.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.