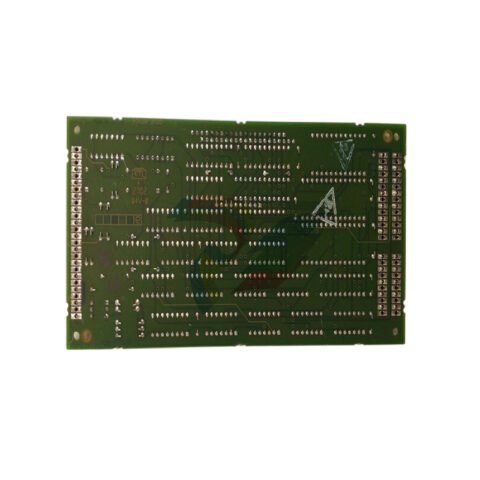

GE Fanuc VMIVME-7486 CPU Processor / Controller

Introducing the GE Fanuc, a benchmark in industrial automation that delivers precision, reliability, and efficiency for a variety of applications. As part of GE's renowned line of automation products, the GE Fanuc model is designed to meet the evolving demands of modern manufacturing and process control environments. This comprehensive product description will delve into the key technical features, usage scenarios, comparisons with other models, and reference related products that complement the GE Fanuc, ensuring you have all the information needed to make an informed decision.

Key Technical Features

The GE Fanuc is engineered with cutting-edge technology that enhances its performance and usability. Key technical features include:

1. Robust Processing Power: The GE Fanuc incorporates high-performance processors that enable fast data processing and real-time system responses, making it ideal for time-sensitive applications in manufacturing and control.

2. Modular Design: This model features a modular architecture that allows for easy expansion and customization. Users can add or remove components as needed to tailor the system to specific operational requirements.

3. Versatile Communication Protocols: GE Fanuc supports a wide range of communication protocols, including Ethernet/IP, Modbus, and PROFIBUS, enabling seamless integration with existing systems and devices for enhanced connectivity.

4. Advanced Control Capabilities: With built-in PID control algorithms and other advanced features, the GE Fanuc facilitates precise control of various processes, ensuring optimal performance and quality.

5. User-Friendly Interface: The intuitive interface simplifies operation and monitoring, allowing users to easily access critical information and make adjustments with minimal training.

6. High Reliability: Designed for harsh industrial environments, the GE Fanuc boasts robust construction and enhanced protection against dust, moisture, and extreme temperatures, ensuring longevity and minimal downtime.

Usage Scenarios

The GE Fanuc is versatile enough to be used across various sectors, including manufacturing, energy, transportation, and process industries. Some typical usage scenarios include:

1. Manufacturing Automation: In production facilities, the GE Fanuc can control robotic systems, assembly lines, and material handling equipment, optimizing throughput and efficiency.

2. Process Control: It is ideal for applications in chemical processing, oil and gas, and food and beverage industries where precise monitoring and control of variables such as temperature, pressure, and flow are critical.

3. Building Management Systems: The GE Fanuc can be integrated into smart building systems to automate HVAC, lighting, and security systems, enhancing energy efficiency and user comfort.

4. Transportation Management: This model can be utilized in traffic control systems, railway signaling, and airport operations, contributing to improved safety and operational efficiency.

5. Renewable Energy: The GE Fanuc is suitable for managing and monitoring renewable energy sources, including wind turbines and solar panels, maximizing energy production and reliability.

Comparison with Other Models

When comparing the GE Fanuc with other models in the GE automation products lineup, such as the GE SR750 or the GE IS200DSPXH2DBD, several distinguishing factors emerge:

1. Processing Capabilities: While the GE SR750 offers advanced motion control features, the GE Fanuc excels in modularity and communication flexibility, making it a more adaptable choice for diverse applications.

2. User Interface: Compared to the GE IS200DSPXH2DBD’s complex interface, the GE Fanuc provides a more user-friendly experience, making it accessible for operators with varying levels of technical expertise.

3. Environmental Tolerance: Models like the GE IS200EDFFH1ABA are designed for specific applications, but the GE Fanuc’s robust construction offers broader applicability across different environments, ensuring reliability under varying conditions.

4. Communication Flexibility: The GE Fanuc stands out with its extensive support for multiple communication protocols, allowing it to integrate seamlessly with a wider range of devices than many of its counterparts.

Reference to Related Models

To provide a comprehensive understanding of the GE Fanuc and its positioning within the GE product ecosystem, here are ten related models worth noting:

1. GE SR750 – Known for its advanced motion control capabilities.

2. GE IC697MDL740 – A reliable option for discrete I/O applications.

3. GE IS200DSFCG1AEB – Offers specialized controls for turbine operations.

4. GE IC660BBA020 – Equipped for analog input/output applications.

5. GE DS200DDTBG2A – Ideal for digital signal processing needs.

6. GE IS200DSPXH2DBD – Focused on sophisticated signal processing.

7. GE IS220PPDAH1A – Designed for precise power distribution applications.

8. GE IC693APU301 – A robust choice for power supply management.

9. GE IS200VTURH1BAC – Tailored for turbine control and monitoring.

10. GE IC695CPE310-ABAH – Known for its high processing capabilities.

In conclusion, the GE Fanuc is an exceptional choice for those seeking a reliable, versatile, and powerful automation solution. Its advanced technical features, user-friendly interface, and adaptability across various sectors make it a standout model in the GE automation products lineup. Whether you're automating manufacturing processes, controlling critical infrastructure, or managing energy resources, the GE Fanuc is designed to meet your needs with efficiency and precision. With its seamless integration capabilities and robust performance, the GE Fanuc empowers organizations to optimize their operations and achieve their automation goals.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE Fanuc is engineered with cutting-edge technology that enhances its performance and usability. Key technical features include:

1. Robust Processing Power: The GE Fanuc incorporates high-performance processors that enable fast data processing and real-time system responses, making it ideal for time-sensitive applications in manufacturing and control.

2. Modular Design: This model features a modular architecture that allows for easy expansion and customization. Users can add or remove components as needed to tailor the system to specific operational requirements.

3. Versatile Communication Protocols: GE Fanuc supports a wide range of communication protocols, including Ethernet/IP, Modbus, and PROFIBUS, enabling seamless integration with existing systems and devices for enhanced connectivity.

4. Advanced Control Capabilities: With built-in PID control algorithms and other advanced features, the GE Fanuc facilitates precise control of various processes, ensuring optimal performance and quality.

5. User-Friendly Interface: The intuitive interface simplifies operation and monitoring, allowing users to easily access critical information and make adjustments with minimal training.

6. High Reliability: Designed for harsh industrial environments, the GE Fanuc boasts robust construction and enhanced protection against dust, moisture, and extreme temperatures, ensuring longevity and minimal downtime.

Usage Scenarios

The GE Fanuc is versatile enough to be used across various sectors, including manufacturing, energy, transportation, and process industries. Some typical usage scenarios include:

1. Manufacturing Automation: In production facilities, the GE Fanuc can control robotic systems, assembly lines, and material handling equipment, optimizing throughput and efficiency.

2. Process Control: It is ideal for applications in chemical processing, oil and gas, and food and beverage industries where precise monitoring and control of variables such as temperature, pressure, and flow are critical.

3. Building Management Systems: The GE Fanuc can be integrated into smart building systems to automate HVAC, lighting, and security systems, enhancing energy efficiency and user comfort.

4. Transportation Management: This model can be utilized in traffic control systems, railway signaling, and airport operations, contributing to improved safety and operational efficiency.

5. Renewable Energy: The GE Fanuc is suitable for managing and monitoring renewable energy sources, including wind turbines and solar panels, maximizing energy production and reliability.

Comparison with Other Models

When comparing the GE Fanuc with other models in the GE automation products lineup, such as the GE SR750 or the GE IS200DSPXH2DBD, several distinguishing factors emerge:

1. Processing Capabilities: While the GE SR750 offers advanced motion control features, the GE Fanuc excels in modularity and communication flexibility, making it a more adaptable choice for diverse applications.

2. User Interface: Compared to the GE IS200DSPXH2DBD’s complex interface, the GE Fanuc provides a more user-friendly experience, making it accessible for operators with varying levels of technical expertise.

3. Environmental Tolerance: Models like the GE IS200EDFFH1ABA are designed for specific applications, but the GE Fanuc’s robust construction offers broader applicability across different environments, ensuring reliability under varying conditions.

4. Communication Flexibility: The GE Fanuc stands out with its extensive support for multiple communication protocols, allowing it to integrate seamlessly with a wider range of devices than many of its counterparts.

Reference to Related Models

To provide a comprehensive understanding of the GE Fanuc and its positioning within the GE product ecosystem, here are ten related models worth noting:

1. GE SR750 – Known for its advanced motion control capabilities.

2. GE IC697MDL740 – A reliable option for discrete I/O applications.

3. GE IS200DSFCG1AEB – Offers specialized controls for turbine operations.

4. GE IC660BBA020 – Equipped for analog input/output applications.

5. GE DS200DDTBG2A – Ideal for digital signal processing needs.

6. GE IS200DSPXH2DBD – Focused on sophisticated signal processing.

7. GE IS220PPDAH1A – Designed for precise power distribution applications.

8. GE IC693APU301 – A robust choice for power supply management.

9. GE IS200VTURH1BAC – Tailored for turbine control and monitoring.

10. GE IC695CPE310-ABAH – Known for its high processing capabilities.

In conclusion, the GE Fanuc is an exceptional choice for those seeking a reliable, versatile, and powerful automation solution. Its advanced technical features, user-friendly interface, and adaptability across various sectors make it a standout model in the GE automation products lineup. Whether you're automating manufacturing processes, controlling critical infrastructure, or managing energy resources, the GE Fanuc is designed to meet your needs with efficiency and precision. With its seamless integration capabilities and robust performance, the GE Fanuc empowers organizations to optimize their operations and achieve their automation goals.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.