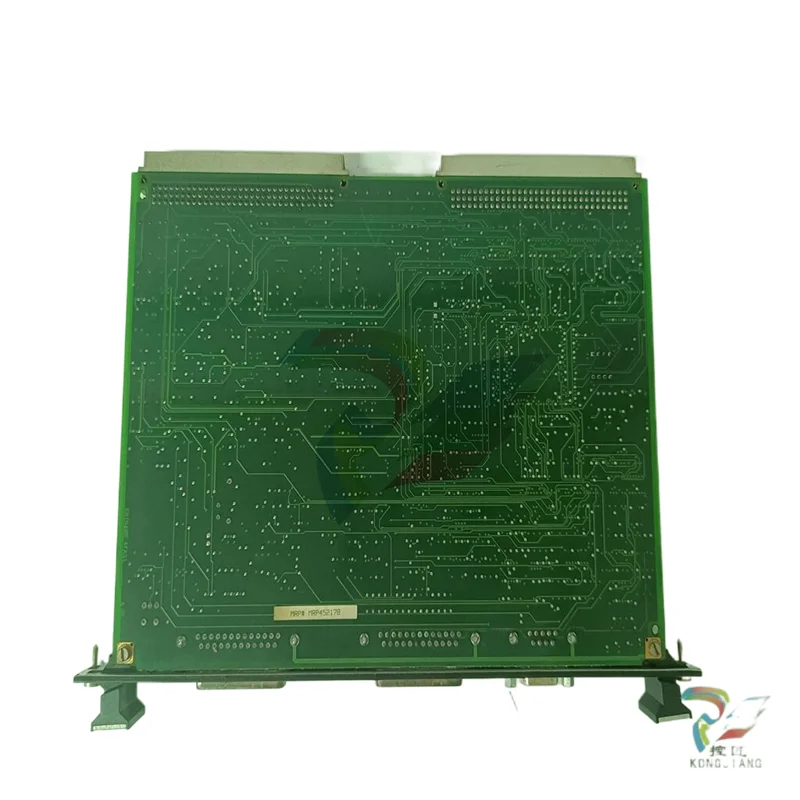

GE Fanuc IS200DDTBG2A Industrial Control Module Termination Card

Introducing the GE Fanuc: a pinnacle of innovation in industrial automation, designed to elevate operational efficiency and streamline complex processes. Known for its reliability and versatility, the GE Fanuc series is an essential component in modern manufacturing and control systems. Let’s delve into the key technical features, usage scenarios, comparisons with other models, and related products that define the GE Fanuc legacy.

**Key Technical Features**

The GE Fanuc integrates advanced technology that ensures superior performance and adaptability. Key technical features include:

1. **Robust Processing Power**: With a high-performance CPU, the GE Fanuc delivers rapid processing speeds, enabling real-time data handling and efficient task execution. This is particularly beneficial in environments where timely responses are critical.

2. **Modular Design**: The modular architecture allows for seamless integration with various GE automation products, enabling users to customize their systems according to specific operational needs. This flexibility is ideal for a wide range of applications, from simple control tasks to complex automation systems.

3. **Enhanced Communication Protocols**: The GE Fanuc supports multiple communication protocols, such as Ethernet/IP, Modbus, and more, facilitating easy connectivity with other devices and systems. This feature ensures that various components within a manufacturing setup can communicate effectively, enhancing overall operational synergy.

4. **Scalability**: The GE Fanuc is designed to grow with your business. Its scalable architecture allows for easy expansion, accommodating future needs without extensive system overhauls. This adaptability makes it a wise investment for companies anticipating growth.

5. **User-Friendly Interface**: The intuitive programming environment simplifies user interaction, allowing engineers to configure and operate the system with ease. This reduces training time and enhances productivity, making it accessible for teams of varying expertise levels.

6. **High Reliability and Durability**: Built to withstand harsh industrial environments, the GE Fanuc series is engineered for longevity. Its robust construction ensures minimal downtime, which is crucial for maintaining operational continuity.

**Usage Scenarios**

The versatility of the GE Fanuc makes it suitable for a myriad of applications across various industries:

– **Manufacturing Automation**: In manufacturing settings, the GE Fanuc can control assembly lines, manage robotic systems, and oversee quality control processes, ensuring that production runs smoothly and efficiently.

– **Process Control**: In industries such as oil and gas, food and beverage, and pharmaceuticals, the GE Fanuc can monitor and control critical processes, ensuring compliance with safety and quality standards.

– **Building Management Systems**: The GE Fanuc can be utilized in HVAC systems, lighting control, and energy management, providing centralized control and improving energy efficiency in commercial buildings.

– **Transport and Logistics**: The system can optimize supply chain operations by managing inventory systems, tracking shipments, and coordinating logistics, thereby enhancing operational efficiency.

**Comparison with Other Models**

When comparing the GE Fanuc to other models within the GE portfolio, several distinctions become evident:

– **GE SR750**: While the GE SR750 focuses on high-speed data processing, the GE Fanuc offers more extensive modularity, making it better suited for customized automation solutions.

– **GE IS200DSPXH2DBD**: The IS200DSPXH2DBD is optimized for specific control tasks, whereas the GE Fanuc provides broader application versatility, making it ideal for diverse industry needs.

– **GE IC697MDL740**: This model is primarily a discrete I/O module that supports specific applications, while the GE Fanuc serves as a central processing unit, offering comprehensive control capabilities.

– **GE IS220PPDAH1A**: Although this model excels in protection relay applications, the GE Fanuc offers a more comprehensive automation solution, integrating multiple functionalities into one system.

**Related Models**

To further illustrate the strengths and compatibility of the GE Fanuc, here are ten related models within the GE automation product range:

1. **GE IC660BBA020**: A versatile base block that complements the GE Fanuc in various configurations.

2. **GE IS200DSFCG1AEB**: A digital signal processor that integrates seamlessly with the GE Fanuc for enhanced processing capabilities.

3. **GE IC693APU301**: An advanced power supply unit that ensures stable performance for the GE Fanuc system.

4. **GE IS200JPDMG1ADC**: A joint processor module that enhances communication and processing within the automation framework.

5. **GE DS200DDTBG2A**: An essential component for data acquisition, complementing the GE Fanuc's data handling capabilities.

6. **GE IS200EDFFH1ABA**: A controller designed for specific applications, which can work alongside the GE Fanuc for optimized performance.

7. **GE IC694PWR331**: A reliable power supply module that supports the operational demands of the GE Fanuc.

8. **GE HE693RTM705**: A remote terminal module that enhances the connectivity of the GE Fanuc in complex setups.

9. **GE VMIVME-7671-421000**: A versatile module that can be integrated with the GE Fanuc for specialized applications.

10. **GE IC200CPU005**: A compact controller that, while designed for smaller applications, shares the reliability and performance standards of the GE Fanuc.

In conclusion, the GE Fanuc stands as a cornerstone of industrial automation, combining cutting-edge technology with robust design to meet the demands of modern manufacturing and control systems. Its adaptability and extensive feature set make it an invaluable asset for businesses looking to enhance operational efficiency and scalability. With a rich ecosystem of related GE automation products, the GE Fanuc is not just a controller; it is a comprehensive solution for the future of automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The GE Fanuc integrates advanced technology that ensures superior performance and adaptability. Key technical features include:

1. **Robust Processing Power**: With a high-performance CPU, the GE Fanuc delivers rapid processing speeds, enabling real-time data handling and efficient task execution. This is particularly beneficial in environments where timely responses are critical.

2. **Modular Design**: The modular architecture allows for seamless integration with various GE automation products, enabling users to customize their systems according to specific operational needs. This flexibility is ideal for a wide range of applications, from simple control tasks to complex automation systems.

3. **Enhanced Communication Protocols**: The GE Fanuc supports multiple communication protocols, such as Ethernet/IP, Modbus, and more, facilitating easy connectivity with other devices and systems. This feature ensures that various components within a manufacturing setup can communicate effectively, enhancing overall operational synergy.

4. **Scalability**: The GE Fanuc is designed to grow with your business. Its scalable architecture allows for easy expansion, accommodating future needs without extensive system overhauls. This adaptability makes it a wise investment for companies anticipating growth.

5. **User-Friendly Interface**: The intuitive programming environment simplifies user interaction, allowing engineers to configure and operate the system with ease. This reduces training time and enhances productivity, making it accessible for teams of varying expertise levels.

6. **High Reliability and Durability**: Built to withstand harsh industrial environments, the GE Fanuc series is engineered for longevity. Its robust construction ensures minimal downtime, which is crucial for maintaining operational continuity.

**Usage Scenarios**

The versatility of the GE Fanuc makes it suitable for a myriad of applications across various industries:

– **Manufacturing Automation**: In manufacturing settings, the GE Fanuc can control assembly lines, manage robotic systems, and oversee quality control processes, ensuring that production runs smoothly and efficiently.

– **Process Control**: In industries such as oil and gas, food and beverage, and pharmaceuticals, the GE Fanuc can monitor and control critical processes, ensuring compliance with safety and quality standards.

– **Building Management Systems**: The GE Fanuc can be utilized in HVAC systems, lighting control, and energy management, providing centralized control and improving energy efficiency in commercial buildings.

– **Transport and Logistics**: The system can optimize supply chain operations by managing inventory systems, tracking shipments, and coordinating logistics, thereby enhancing operational efficiency.

**Comparison with Other Models**

When comparing the GE Fanuc to other models within the GE portfolio, several distinctions become evident:

– **GE SR750**: While the GE SR750 focuses on high-speed data processing, the GE Fanuc offers more extensive modularity, making it better suited for customized automation solutions.

– **GE IS200DSPXH2DBD**: The IS200DSPXH2DBD is optimized for specific control tasks, whereas the GE Fanuc provides broader application versatility, making it ideal for diverse industry needs.

– **GE IC697MDL740**: This model is primarily a discrete I/O module that supports specific applications, while the GE Fanuc serves as a central processing unit, offering comprehensive control capabilities.

– **GE IS220PPDAH1A**: Although this model excels in protection relay applications, the GE Fanuc offers a more comprehensive automation solution, integrating multiple functionalities into one system.

**Related Models**

To further illustrate the strengths and compatibility of the GE Fanuc, here are ten related models within the GE automation product range:

1. **GE IC660BBA020**: A versatile base block that complements the GE Fanuc in various configurations.

2. **GE IS200DSFCG1AEB**: A digital signal processor that integrates seamlessly with the GE Fanuc for enhanced processing capabilities.

3. **GE IC693APU301**: An advanced power supply unit that ensures stable performance for the GE Fanuc system.

4. **GE IS200JPDMG1ADC**: A joint processor module that enhances communication and processing within the automation framework.

5. **GE DS200DDTBG2A**: An essential component for data acquisition, complementing the GE Fanuc's data handling capabilities.

6. **GE IS200EDFFH1ABA**: A controller designed for specific applications, which can work alongside the GE Fanuc for optimized performance.

7. **GE IC694PWR331**: A reliable power supply module that supports the operational demands of the GE Fanuc.

8. **GE HE693RTM705**: A remote terminal module that enhances the connectivity of the GE Fanuc in complex setups.

9. **GE VMIVME-7671-421000**: A versatile module that can be integrated with the GE Fanuc for specialized applications.

10. **GE IC200CPU005**: A compact controller that, while designed for smaller applications, shares the reliability and performance standards of the GE Fanuc.

In conclusion, the GE Fanuc stands as a cornerstone of industrial automation, combining cutting-edge technology with robust design to meet the demands of modern manufacturing and control systems. Its adaptability and extensive feature set make it an invaluable asset for businesses looking to enhance operational efficiency and scalability. With a rich ecosystem of related GE automation products, the GE Fanuc is not just a controller; it is a comprehensive solution for the future of automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.