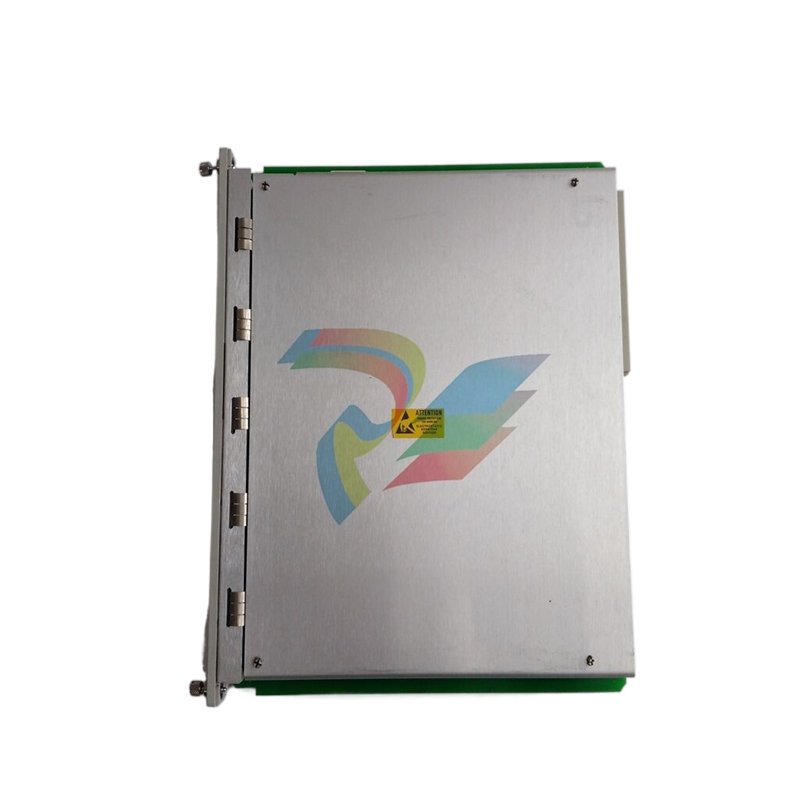

BENTLY 3500/45 176449-04 Industrial Vibration Monitoring Module

Introducing the BENTLY 3500/45 176449-04: A Pinnacle of Monitoring Technology

The BENTLY 3500/45 176449-04 is a cutting-edge monitoring solution designed to enhance the reliability and performance of your industrial machinery. As part of BENTLY's renowned suite of automation products, the 3500/45 model stands out for its ability to deliver precise, real-time monitoring and diagnostics, ensuring the optimal functioning of critical equipment in various sectors.

Key Technical Features

The BENTLY 3500/45 176449-04 is engineered with advanced technology that supports a wide range of functionalities:

1. **Vibration Monitoring**: This model features high-fidelity vibration sensors that provide detailed analysis of machinery health. With its ability to detect subtle changes in vibration patterns, the 3500/45 can predict potential failures before they escalate.

2. **Dynamic Signal Processing**: Leveraging advanced algorithms, the 3500/45 offers dynamic signal processing capabilities, enabling it to filter noise and zero in on critical data. This results in exceptionally accurate readings and early warning signals.

3. **Versatile Input Options**: The 3500/45 supports a variety of input types, including 4-20 mA, voltage, and digital signals, making it compatible with a vast array of sensors and instrumentation. This flexibility allows for seamless integration into existing systems.

4. **User-Friendly Interface**: With its intuitive design, the 3500/45 ensures easy navigation for operators and maintenance personnel. The graphical interface provides clear visualizations of data trends, helping to identify issues quickly.

5. **Robust Connectivity**: The BENTLY 3500/45 is equipped with multiple communication protocols, including Modbus and Ethernet, ensuring easy integration with other systems and facilitating remote monitoring capabilities.

Usage Scenarios

The versatility of the BENTLY 3500/45 176449-04 makes it suitable for a variety of applications across different industries:

– **Oil and Gas**: In oil rigs and refineries, the 3500/45 can monitor pumps, compressors, and turbines, providing vital data that can help prevent costly downtime due to equipment failure.

– **Power Generation**: In power plants, this model is invaluable for monitoring generators and turbines. Its predictive maintenance capabilities ensure that machinery operates within optimal conditions, enhancing efficiency and reducing operational costs.

– **Manufacturing**: The 3500/45 can be deployed in manufacturing facilities to monitor conveyor belts, motors, and other critical machinery. By identifying abnormalities early, it helps maintain productivity and minimize unplanned outages.

– **Mining**: In the mining sector, where machinery is subjected to extreme conditions, the robust nature of the BENTLY 3500/45 ensures reliable monitoring of crushers, grinders, and other heavy equipment.

Comparison with Other Models

When compared to other models in the BENTLY lineup, the 3500/45 176449-04 excels in several key areas:

– **BENTLY 3500/20 125744-02**: While the 3500/20 offers basic vibration monitoring capabilities, the 3500/45 provides enhanced signal processing and more input options, making it a superior choice for comprehensive monitoring.

– **BENTLY 3500/40M**: Although the 3500/40M is designed for a similar purpose, the 3500/45's advanced diagnostics and user-friendly interface make it a more powerful tool for predictive maintenance.

– **BENTLY 3500/34**: The 3500/34 is limited in its application range compared to the 3500/45, which supports a wider variety of industrial sensors and instrumentation.

– **BENTLY 3500/50**: The 3500/50 focuses primarily on machinery protection, while the 3500/45 encompasses both monitoring and diagnostics, providing a more well-rounded solution for equipment health management.

Related Models

For those considering the BENTLY 3500/45 176449-04, it's helpful to explore other models within the BENTLY automation products family that may meet specific needs:

1. **BENTLY 3500/25**: Ideal for monitoring machine conditions, though less advanced in signal processing than the 3500/45.

2. **BENTLY 3500/40M**: Offers machinery protection but lacks some of the advanced monitoring features of the 3500/45.

3. **BENTLY 3500/22M**: Provides basic monitoring capabilities, suitable for less critical applications.

4. **BENTLY 3500/92**: A solid choice for high-speed machinery monitoring but with limited diagnostic capabilities.

5. **BENTLY 3500/53**: Focuses on advanced diagnostics; however, it may not have the same comprehensive monitoring capabilities as the 3500/45.

6. **BENTLY 3500/64M**: Best for specific machinery types but lacks the versatility of the 3500/45.

7. **BENTLY 3500/15**: A more basic model, best suited for straightforward monitoring tasks.

8. **BENTLY 3300/20**: Designed for similar applications but with fewer features compared to the 3500/45.

9. **BENTLY 3500/42M**: Offers good performance, although the advanced diagnostics of the 3500/45 provide a distinct advantage.

10. **BENTLY Nevada**: Known for reliability, but the 3500/45's modern features set it apart in terms of technology and usability.

In conclusion, the BENTLY 3500/45 176449-04 is an unparalleled solution for industrial monitoring, blending advanced technology with user-friendly design. Its versatility across various applications, combined with superior performance compared to other models, makes it an essential tool for any facility aiming to enhance operational reliability and efficiency. Explore the capabilities of BENTLY automation products and elevate your machinery monitoring strategy today.

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY 3500/45 176449-04 is a cutting-edge monitoring solution designed to enhance the reliability and performance of your industrial machinery. As part of BENTLY's renowned suite of automation products, the 3500/45 model stands out for its ability to deliver precise, real-time monitoring and diagnostics, ensuring the optimal functioning of critical equipment in various sectors.

Key Technical Features

The BENTLY 3500/45 176449-04 is engineered with advanced technology that supports a wide range of functionalities:

1. **Vibration Monitoring**: This model features high-fidelity vibration sensors that provide detailed analysis of machinery health. With its ability to detect subtle changes in vibration patterns, the 3500/45 can predict potential failures before they escalate.

2. **Dynamic Signal Processing**: Leveraging advanced algorithms, the 3500/45 offers dynamic signal processing capabilities, enabling it to filter noise and zero in on critical data. This results in exceptionally accurate readings and early warning signals.

3. **Versatile Input Options**: The 3500/45 supports a variety of input types, including 4-20 mA, voltage, and digital signals, making it compatible with a vast array of sensors and instrumentation. This flexibility allows for seamless integration into existing systems.

4. **User-Friendly Interface**: With its intuitive design, the 3500/45 ensures easy navigation for operators and maintenance personnel. The graphical interface provides clear visualizations of data trends, helping to identify issues quickly.

5. **Robust Connectivity**: The BENTLY 3500/45 is equipped with multiple communication protocols, including Modbus and Ethernet, ensuring easy integration with other systems and facilitating remote monitoring capabilities.

Usage Scenarios

The versatility of the BENTLY 3500/45 176449-04 makes it suitable for a variety of applications across different industries:

– **Oil and Gas**: In oil rigs and refineries, the 3500/45 can monitor pumps, compressors, and turbines, providing vital data that can help prevent costly downtime due to equipment failure.

– **Power Generation**: In power plants, this model is invaluable for monitoring generators and turbines. Its predictive maintenance capabilities ensure that machinery operates within optimal conditions, enhancing efficiency and reducing operational costs.

– **Manufacturing**: The 3500/45 can be deployed in manufacturing facilities to monitor conveyor belts, motors, and other critical machinery. By identifying abnormalities early, it helps maintain productivity and minimize unplanned outages.

– **Mining**: In the mining sector, where machinery is subjected to extreme conditions, the robust nature of the BENTLY 3500/45 ensures reliable monitoring of crushers, grinders, and other heavy equipment.

Comparison with Other Models

When compared to other models in the BENTLY lineup, the 3500/45 176449-04 excels in several key areas:

– **BENTLY 3500/20 125744-02**: While the 3500/20 offers basic vibration monitoring capabilities, the 3500/45 provides enhanced signal processing and more input options, making it a superior choice for comprehensive monitoring.

– **BENTLY 3500/40M**: Although the 3500/40M is designed for a similar purpose, the 3500/45's advanced diagnostics and user-friendly interface make it a more powerful tool for predictive maintenance.

– **BENTLY 3500/34**: The 3500/34 is limited in its application range compared to the 3500/45, which supports a wider variety of industrial sensors and instrumentation.

– **BENTLY 3500/50**: The 3500/50 focuses primarily on machinery protection, while the 3500/45 encompasses both monitoring and diagnostics, providing a more well-rounded solution for equipment health management.

Related Models

For those considering the BENTLY 3500/45 176449-04, it's helpful to explore other models within the BENTLY automation products family that may meet specific needs:

1. **BENTLY 3500/25**: Ideal for monitoring machine conditions, though less advanced in signal processing than the 3500/45.

2. **BENTLY 3500/40M**: Offers machinery protection but lacks some of the advanced monitoring features of the 3500/45.

3. **BENTLY 3500/22M**: Provides basic monitoring capabilities, suitable for less critical applications.

4. **BENTLY 3500/92**: A solid choice for high-speed machinery monitoring but with limited diagnostic capabilities.

5. **BENTLY 3500/53**: Focuses on advanced diagnostics; however, it may not have the same comprehensive monitoring capabilities as the 3500/45.

6. **BENTLY 3500/64M**: Best for specific machinery types but lacks the versatility of the 3500/45.

7. **BENTLY 3500/15**: A more basic model, best suited for straightforward monitoring tasks.

8. **BENTLY 3300/20**: Designed for similar applications but with fewer features compared to the 3500/45.

9. **BENTLY 3500/42M**: Offers good performance, although the advanced diagnostics of the 3500/45 provide a distinct advantage.

10. **BENTLY Nevada**: Known for reliability, but the 3500/45's modern features set it apart in terms of technology and usability.

In conclusion, the BENTLY 3500/45 176449-04 is an unparalleled solution for industrial monitoring, blending advanced technology with user-friendly design. Its versatility across various applications, combined with superior performance compared to other models, makes it an essential tool for any facility aiming to enhance operational reliability and efficiency. Explore the capabilities of BENTLY automation products and elevate your machinery monitoring strategy today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.