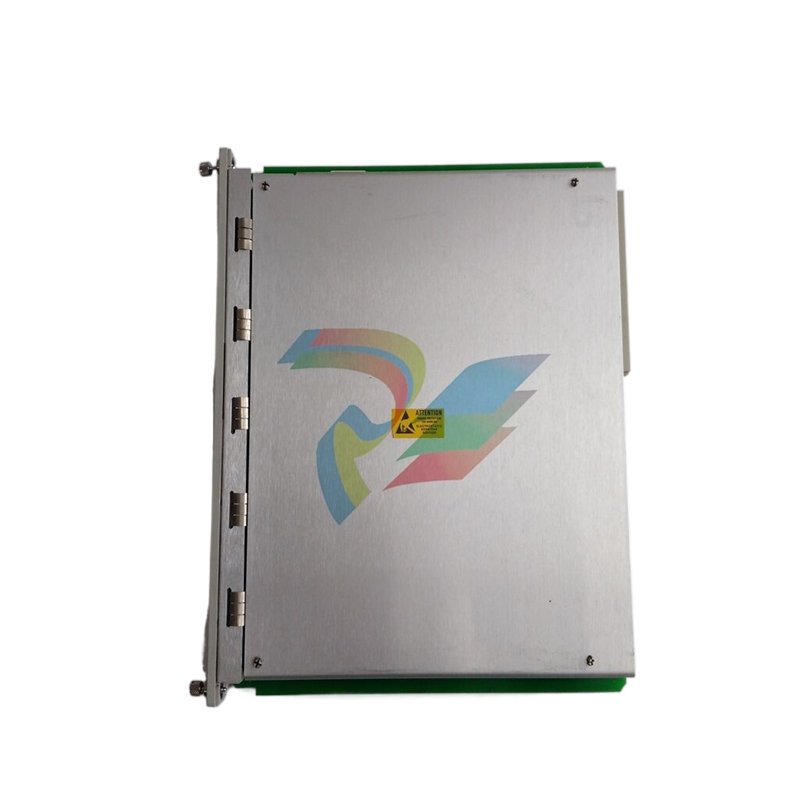

BENTLY 330130-040-00-00 Vibration Monitoring System Module

Introducing the BENTLY 330130-040-00-00, a robust and highly efficient monitoring solution designed to meet the rigorous demands of industrial applications. This model stands out within the BENTLY automation products line, offering precision, reliability, and advanced functionality that are essential for effective machinery management.

### Key Technical Features

The BENTLY 330130-040-00-00 is engineered with cutting-edge technology to provide unparalleled performance. Its key features include:

– **Multi-Channel Monitoring**: Capable of monitoring multiple parameters simultaneously, allowing for real-time data collection and analysis, which is crucial for predictive maintenance.

– **High Sensitivity**: The device includes high-sensitivity sensors that can detect even the slightest variations in machinery performance, enabling early detection of potential issues.

– **Flexible Configuration Options**: This model supports a range of configuration options, making it adaptable to various industrial setups and specific user requirements.

– **User-Friendly Interface**: The intuitive user interface simplifies setup and operation, ensuring that users can easily navigate through the system’s capabilities.

– **Durable Design**: Built to withstand harsh industrial environments, the BENTLY 330130-040-00-00 features a rugged housing that protects it from dust, moisture, and other environmental factors.

– **Integration Capabilities**: Seamlessly integrates with existing BENTLY automation products, enhancing overall system interoperability and functionality.

### Usage Scenarios

The versatility of the BENTLY 330130-040-00-00 makes it suitable for various applications across multiple industries.

1. **Oil and Gas**: In oil and gas extraction and processing facilities, real-time monitoring of rotating machinery is critical. The BENTLY 330130-040-00-00 provides accurate data on vibration and temperature, helping prevent costly downtime.

2. **Power Generation**: Power plants can utilize this model to monitor turbines and generators, ensuring they operate within optimal limits and reducing the risk of catastrophic failures.

3. **Manufacturing**: In manufacturing facilities, the BENTLY 330130-040-00-00 is essential for monitoring critical machinery, allowing for predictive maintenance that minimizes operational interruptions.

4. **Mining**: The rugged nature of this device makes it ideal for the mining industry, where it can withstand challenging environments while continuously monitoring equipment performance.

### Comparison with Other Models

When compared to other models within the BENTLY product range, the BENTLY 330130-040-00-00 holds a distinct competitive edge. For instance, while the BENTLY 3500/20 125744-02 offers similar monitoring capabilities, the 330130-040-00-00 is designed with enhanced sensitivity and multi-channel features that cater to more complex applications.

In contrast to the BENTLY 3500/42M, which focuses on specific machine types, the BENTLY 330130-040-00-00's versatility makes it suitable for a broader spectrum of machinery. Additionally, the robust design of the 330130-040-00-00 outperforms the more delicate models like the BENTLY 3500/50, which may not be as resilient in extreme conditions.

### Related Models

For those exploring options within the BENTLY automation products line, consider these related models:

1. **BENTLY 3500/40M**: Offers advanced monitoring features tailored for machinery health.

2. **BENTLY 330500-00-00**: Known for its reliability and precision in monitoring vibration.

3. **BENTLY 3500/25**: Focuses on critical machine monitoring, ideal for preventive maintenance.

4. **BENTLY 3500/34**: Provides additional analytical capabilities for deeper insights into machinery performance.

5. **BENTLY 3500/42M**: A specialized model for specific machinery types, with unique monitoring capabilities.

6. **BENTLY 3500/53**: A robust option for multi-channel monitoring with extensive integration features.

7. **BENTLY 330104-00-25-10-02-00**: Ideal for monitoring various industrial processes with high accuracy.

8. **BENTLY 3500/15**: A cost-effective solution for essential monitoring needs in industrial environments.

9. **BENTLY 3500/92**: Focuses on advanced data collection and diagnostic capabilities.

10. **BENTLY Nevada**: A comprehensive monitoring system that integrates various BENTLY models for a holistic approach to machinery health.

### Conclusion

The BENTLY 330130-040-00-00 is more than just a monitoring device; it is a critical tool for enhancing operational efficiency and reliability across various industries. Its advanced features, adaptability, and robust design make it an indispensable asset for businesses looking to optimize their machinery performance. Whether you're in oil and gas, power generation, manufacturing, or mining, this model provides the reliability and precision needed to ensure your operations run smoothly.

As part of the esteemed BENTLY automation products portfolio, the BENTLY 330130-040-00-00 stands as a testament to quality and innovation, setting the standard for machinery monitoring solutions. Invest in the BENTLY 330130-040-00-00 today and take a proactive approach to machinery health and performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

### Key Technical Features

The BENTLY 330130-040-00-00 is engineered with cutting-edge technology to provide unparalleled performance. Its key features include:

– **Multi-Channel Monitoring**: Capable of monitoring multiple parameters simultaneously, allowing for real-time data collection and analysis, which is crucial for predictive maintenance.

– **High Sensitivity**: The device includes high-sensitivity sensors that can detect even the slightest variations in machinery performance, enabling early detection of potential issues.

– **Flexible Configuration Options**: This model supports a range of configuration options, making it adaptable to various industrial setups and specific user requirements.

– **User-Friendly Interface**: The intuitive user interface simplifies setup and operation, ensuring that users can easily navigate through the system’s capabilities.

– **Durable Design**: Built to withstand harsh industrial environments, the BENTLY 330130-040-00-00 features a rugged housing that protects it from dust, moisture, and other environmental factors.

– **Integration Capabilities**: Seamlessly integrates with existing BENTLY automation products, enhancing overall system interoperability and functionality.

### Usage Scenarios

The versatility of the BENTLY 330130-040-00-00 makes it suitable for various applications across multiple industries.

1. **Oil and Gas**: In oil and gas extraction and processing facilities, real-time monitoring of rotating machinery is critical. The BENTLY 330130-040-00-00 provides accurate data on vibration and temperature, helping prevent costly downtime.

2. **Power Generation**: Power plants can utilize this model to monitor turbines and generators, ensuring they operate within optimal limits and reducing the risk of catastrophic failures.

3. **Manufacturing**: In manufacturing facilities, the BENTLY 330130-040-00-00 is essential for monitoring critical machinery, allowing for predictive maintenance that minimizes operational interruptions.

4. **Mining**: The rugged nature of this device makes it ideal for the mining industry, where it can withstand challenging environments while continuously monitoring equipment performance.

### Comparison with Other Models

When compared to other models within the BENTLY product range, the BENTLY 330130-040-00-00 holds a distinct competitive edge. For instance, while the BENTLY 3500/20 125744-02 offers similar monitoring capabilities, the 330130-040-00-00 is designed with enhanced sensitivity and multi-channel features that cater to more complex applications.

In contrast to the BENTLY 3500/42M, which focuses on specific machine types, the BENTLY 330130-040-00-00's versatility makes it suitable for a broader spectrum of machinery. Additionally, the robust design of the 330130-040-00-00 outperforms the more delicate models like the BENTLY 3500/50, which may not be as resilient in extreme conditions.

### Related Models

For those exploring options within the BENTLY automation products line, consider these related models:

1. **BENTLY 3500/40M**: Offers advanced monitoring features tailored for machinery health.

2. **BENTLY 330500-00-00**: Known for its reliability and precision in monitoring vibration.

3. **BENTLY 3500/25**: Focuses on critical machine monitoring, ideal for preventive maintenance.

4. **BENTLY 3500/34**: Provides additional analytical capabilities for deeper insights into machinery performance.

5. **BENTLY 3500/42M**: A specialized model for specific machinery types, with unique monitoring capabilities.

6. **BENTLY 3500/53**: A robust option for multi-channel monitoring with extensive integration features.

7. **BENTLY 330104-00-25-10-02-00**: Ideal for monitoring various industrial processes with high accuracy.

8. **BENTLY 3500/15**: A cost-effective solution for essential monitoring needs in industrial environments.

9. **BENTLY 3500/92**: Focuses on advanced data collection and diagnostic capabilities.

10. **BENTLY Nevada**: A comprehensive monitoring system that integrates various BENTLY models for a holistic approach to machinery health.

### Conclusion

The BENTLY 330130-040-00-00 is more than just a monitoring device; it is a critical tool for enhancing operational efficiency and reliability across various industries. Its advanced features, adaptability, and robust design make it an indispensable asset for businesses looking to optimize their machinery performance. Whether you're in oil and gas, power generation, manufacturing, or mining, this model provides the reliability and precision needed to ensure your operations run smoothly.

As part of the esteemed BENTLY automation products portfolio, the BENTLY 330130-040-00-00 stands as a testament to quality and innovation, setting the standard for machinery monitoring solutions. Invest in the BENTLY 330130-040-00-00 today and take a proactive approach to machinery health and performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.