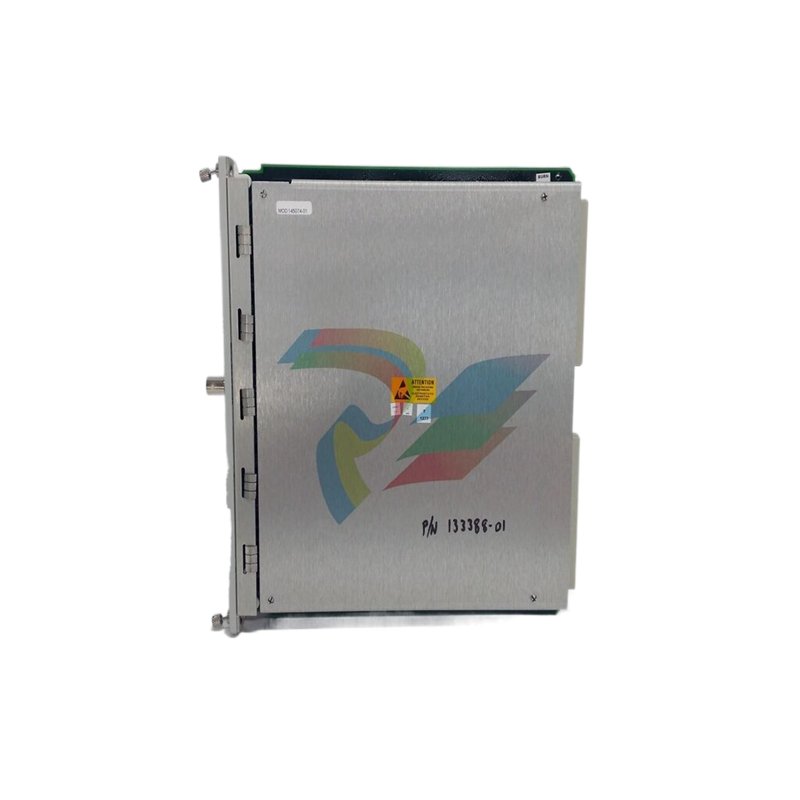

BENTLY 3500/15 127610-01 Control Module

Introducing the BENTLY 3500/15: A Revolution in Condition Monitoring

The BENTLY 3500/15 is a sophisticated condition monitoring system designed to enhance the reliability and performance of industrial machinery. As part of the renowned BENTLY automation products line, the 3500/15 offers unparalleled precision in monitoring and diagnostics, making it essential for any operational setting where machinery uptime is critical.

Key Technical Features

At the heart of the BENTLY 3500/15 lies its advanced technology, which includes real-time data acquisition and processing capabilities. This model features a state-of-the-art vibration monitoring system that provides high-resolution measurements, enabling users to detect even the smallest changes in machine performance. The BENTLY 3500/15 supports multiple input channels, allowing for the simultaneous monitoring of various parameters, including vibration, temperature, and speed.

One of the standout features of the BENTLY 3500/15 is its ease of integration with existing automation frameworks. It utilizes a robust communication protocol, ensuring seamless connectivity with other BENTLY automation products and third-party systems. The user-friendly interface, complete with intuitive software, enables operators to quickly analyze data and generate actionable insights without extensive training.

Additionally, the BENTLY 3500/15 is designed with a rugged, industrial-grade chassis, ensuring durability in harsh environments. Its advanced signal processing capabilities, including frequency analysis and envelope detection, allow for the early detection of potential failures, significantly reducing the risk of costly downtime.

Usage Scenarios

The BENTLY 3500/15 is ideal for a wide range of industrial applications, including power generation, oil and gas extraction, water treatment facilities, and manufacturing plants. In power generation, for example, the 3500/15 can be employed to monitor turbine performance, providing critical insights that help prevent mechanical failures. Similarly, in oil and gas applications, the system can be used to monitor pump and compressor health, ensuring that production remains uninterrupted.

In manufacturing, the versatility of the BENTLY 3500/15 enables it to be used on various equipment types, from conveyors to motors. By monitoring equipment health in real time, organizations can implement predictive maintenance strategies, optimizing operational efficiency and extending the lifespan of critical assets.

Comparison with Other Models

When compared to other models in the BENTLY product line, such as the BENTLY 3500/20 and BENTLY 3500/45, the 3500/15 stands out for its enhanced vibration monitoring capabilities. While the 3500/20 focuses on advanced process control, the 3500/15 offers a more specialized approach for vibration analysis, making it the preferred choice for facilities where vibration diagnostics are paramount.

In contrast to the BENTLY 3500/40M, which emphasizes temperature and pressure monitoring, the 3500/15 excels in providing insights specifically related to machine vibrations. This specialization allows organizations to tailor their monitoring solutions to their unique needs, ensuring they have the most relevant data for effective decision-making.

Moreover, when comparing the BENTLY 3500/15 to models like the BENTLY 3500/92 or the BENTLY 3500/25, the 3500/15’s real-time data processing capabilities offer a significant advantage in scenarios requiring immediate feedback on equipment health. While the other models may provide comprehensive monitoring solutions, the focused expertise of the 3500/15 in vibration diagnostics makes it an invaluable tool for proactive maintenance.

Related Models

The BENTLY 3500/15 is part of a broader family of products designed to enhance industrial monitoring and automation. Here are ten related models that complement the capabilities of the BENTLY 3500/15:

1. BENTLY 3500/20 125744-02: Specialized in advanced process control.

2. BENTLY 3500/45 176449-04: Designed for comprehensive machinery protection.

3. BENTLY 3500/34: Offers extensive machinery health monitoring features.

4. BENTLY 3500/42M: Focuses on monitoring multiple parameters simultaneously.

5. BENTLY 3500/50: Known for its advanced signal processing capabilities.

6. BENTLY 3500/92: Provides in-depth diagnostics for various equipment types.

7. BENTLY 3500/25: A versatile model for vibration and temperature monitoring.

8. BENTLY 3500/53: Offers real-time monitoring with enhanced user interfaces.

9. BENTLY 3500/40M: Emphasizes temperature and pressure monitoring for critical applications.

10. BENTLY 3500/72M: Known for its high-performance data acquisition capabilities.

Conclusion

In an increasingly competitive industrial landscape, the BENTLY 3500/15 stands out as a crucial asset for organizations seeking to optimize their machinery performance and reliability. By leveraging cutting-edge technology and specialized monitoring capabilities, this model empowers users to implement effective maintenance strategies, minimize operational risks, and ultimately drive productivity.

Explore the full potential of BENTLY automation products with the BENTLY 3500/15, and experience the difference that advanced condition monitoring can make in your industrial operations. Embrace the future of machinery health management today.

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY 3500/15 is a sophisticated condition monitoring system designed to enhance the reliability and performance of industrial machinery. As part of the renowned BENTLY automation products line, the 3500/15 offers unparalleled precision in monitoring and diagnostics, making it essential for any operational setting where machinery uptime is critical.

Key Technical Features

At the heart of the BENTLY 3500/15 lies its advanced technology, which includes real-time data acquisition and processing capabilities. This model features a state-of-the-art vibration monitoring system that provides high-resolution measurements, enabling users to detect even the smallest changes in machine performance. The BENTLY 3500/15 supports multiple input channels, allowing for the simultaneous monitoring of various parameters, including vibration, temperature, and speed.

One of the standout features of the BENTLY 3500/15 is its ease of integration with existing automation frameworks. It utilizes a robust communication protocol, ensuring seamless connectivity with other BENTLY automation products and third-party systems. The user-friendly interface, complete with intuitive software, enables operators to quickly analyze data and generate actionable insights without extensive training.

Additionally, the BENTLY 3500/15 is designed with a rugged, industrial-grade chassis, ensuring durability in harsh environments. Its advanced signal processing capabilities, including frequency analysis and envelope detection, allow for the early detection of potential failures, significantly reducing the risk of costly downtime.

Usage Scenarios

The BENTLY 3500/15 is ideal for a wide range of industrial applications, including power generation, oil and gas extraction, water treatment facilities, and manufacturing plants. In power generation, for example, the 3500/15 can be employed to monitor turbine performance, providing critical insights that help prevent mechanical failures. Similarly, in oil and gas applications, the system can be used to monitor pump and compressor health, ensuring that production remains uninterrupted.

In manufacturing, the versatility of the BENTLY 3500/15 enables it to be used on various equipment types, from conveyors to motors. By monitoring equipment health in real time, organizations can implement predictive maintenance strategies, optimizing operational efficiency and extending the lifespan of critical assets.

Comparison with Other Models

When compared to other models in the BENTLY product line, such as the BENTLY 3500/20 and BENTLY 3500/45, the 3500/15 stands out for its enhanced vibration monitoring capabilities. While the 3500/20 focuses on advanced process control, the 3500/15 offers a more specialized approach for vibration analysis, making it the preferred choice for facilities where vibration diagnostics are paramount.

In contrast to the BENTLY 3500/40M, which emphasizes temperature and pressure monitoring, the 3500/15 excels in providing insights specifically related to machine vibrations. This specialization allows organizations to tailor their monitoring solutions to their unique needs, ensuring they have the most relevant data for effective decision-making.

Moreover, when comparing the BENTLY 3500/15 to models like the BENTLY 3500/92 or the BENTLY 3500/25, the 3500/15’s real-time data processing capabilities offer a significant advantage in scenarios requiring immediate feedback on equipment health. While the other models may provide comprehensive monitoring solutions, the focused expertise of the 3500/15 in vibration diagnostics makes it an invaluable tool for proactive maintenance.

Related Models

The BENTLY 3500/15 is part of a broader family of products designed to enhance industrial monitoring and automation. Here are ten related models that complement the capabilities of the BENTLY 3500/15:

1. BENTLY 3500/20 125744-02: Specialized in advanced process control.

2. BENTLY 3500/45 176449-04: Designed for comprehensive machinery protection.

3. BENTLY 3500/34: Offers extensive machinery health monitoring features.

4. BENTLY 3500/42M: Focuses on monitoring multiple parameters simultaneously.

5. BENTLY 3500/50: Known for its advanced signal processing capabilities.

6. BENTLY 3500/92: Provides in-depth diagnostics for various equipment types.

7. BENTLY 3500/25: A versatile model for vibration and temperature monitoring.

8. BENTLY 3500/53: Offers real-time monitoring with enhanced user interfaces.

9. BENTLY 3500/40M: Emphasizes temperature and pressure monitoring for critical applications.

10. BENTLY 3500/72M: Known for its high-performance data acquisition capabilities.

Conclusion

In an increasingly competitive industrial landscape, the BENTLY 3500/15 stands out as a crucial asset for organizations seeking to optimize their machinery performance and reliability. By leveraging cutting-edge technology and specialized monitoring capabilities, this model empowers users to implement effective maintenance strategies, minimize operational risks, and ultimately drive productivity.

Explore the full potential of BENTLY automation products with the BENTLY 3500/15, and experience the difference that advanced condition monitoring can make in your industrial operations. Embrace the future of machinery health management today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.