BENTLY Nevada TM501-AXX-B00-C00-D00-E00-G00, Precision Vibration Transmission Solution

Introducing the BENTLY Nevada: The Pinnacle of Condition Monitoring and Machinery Protection

The BENTLY Nevada series, renowned for its precision and reliability, is at the forefront of industrial automation and condition monitoring. The BENTLY Nevada model exemplifies cutting-edge technology through its innovative design and robust features, making it an invaluable asset for industries that demand unwavering performance and operational efficiency.

Key Technical Features

The BENTLY Nevada is engineered with a suite of advanced features that set it apart from conventional monitoring systems. At its core, this model integrates advanced vibration monitoring capabilities, enabling real-time assessments of machinery health. Key features include:

1. **High-Precision Sensors**: The BENTLY Nevada utilizes state-of-the-art vibration sensors, which deliver accurate data on machine performance and health. This enables early detection of potential issues, allowing for timely intervention and minimized downtime.

2. **Multi-Channel Capability**: With the ability to monitor multiple channels simultaneously, the BENTLY Nevada allows for comprehensive analysis of various machinery elements, making it ideal for complex industrial environments.

3. **Robust Data Processing**: Equipped with sophisticated algorithms, the BENTLY Nevada processes vast amounts of data quickly and efficiently. This ensures that operators receive actionable insights in real-time, facilitating proactive maintenance strategies.

4. **User-Friendly Interface**: The intuitive interface of the BENTLY Nevada simplifies operation and monitoring. The graphical displays and easy navigation empower users to access critical information without extensive training.

5. **Integration with BENTLY Automation Products**: Designed to seamlessly integrate with other BENTLY automation products, the Nevada model enhances overall system performance. This interoperability enables users to create a comprehensive monitoring solution tailored to specific operational requirements.

Usage Scenarios

The BENTLY Nevada is ideally suited for a variety of industrial applications, including but not limited to:

– **Power Generation**: In power plants, the BENTLY Nevada monitors rotating equipment such as turbines and generators. By ensuring optimal performance, it helps prevent catastrophic failures that could result in costly outages.

– **Oil and Gas**: In the oil and gas sector, the BENTLY Nevada is critical for monitoring pumps, compressors, and other vital machinery. Its early warning capabilities are essential for maintaining operational integrity and safety in high-risk environments.

– **Manufacturing**: In manufacturing facilities, the BENTLY Nevada provides real-time insights into the health of production equipment. By identifying issues before they escalate, companies can enhance productivity and reduce maintenance costs.

– **Mining and Metals**: The harsh conditions found in mining and metals operations make the BENTLY Nevada an ideal choice for monitoring heavy machinery. Its durability ensures reliable performance even in the most challenging environments.

Comparison with Other Models

When comparing the BENTLY Nevada with other models in the BENTLY lineup, its unique features and capabilities come to light. For example:

– **BENTLY 3500 Series**: While the BENTLY 3500 series offers robust monitoring capabilities, the BENTLY Nevada enhances these features with improved data processing and user interface design, making it easier for operators to gain insights.

– **BENTLY 3300 Series**: The BENTLY 3300 series focuses primarily on vibration monitoring, but the BENTLY Nevada expands on this by incorporating multi-channel capabilities and advanced analytics, catering to more complex industrial applications.

– **BENTLY 3500/40M**: Although the BENTLY 3500/40M provides exceptional machinery protection, the BENTLY Nevada's superior sensor technology and integration options position it as the more advanced choice for modern automation needs.

Related Models

The BENTLY Nevada is part of a comprehensive family of products designed for various monitoring and automation needs. Some related models include:

1. **BENTLY 3500/20 125744-02**: A versatile monitoring solution ideal for various industrial applications.

2. **BENTLY 3500/45 176449-04**: Known for its reliability in monitoring rotating machinery.

3. **BENTLY 60M100-00**: A specialized model designed for specific automation scenarios.

4. **BENTLY 3500/34**: This model focuses on critical machinery monitoring and protection.

5. **BENTLY 3500/42M**: Offers enhanced protection features for machinery in high-stakes environments.

6. **BENTLY 330500-00-00**: A robust choice for overall equipment health monitoring.

7. **BENTLY 3500/50**: Provides comprehensive monitoring capabilities for various applications.

8. **BENTLY 3500/53**: Tailored for advanced condition monitoring in complex systems.

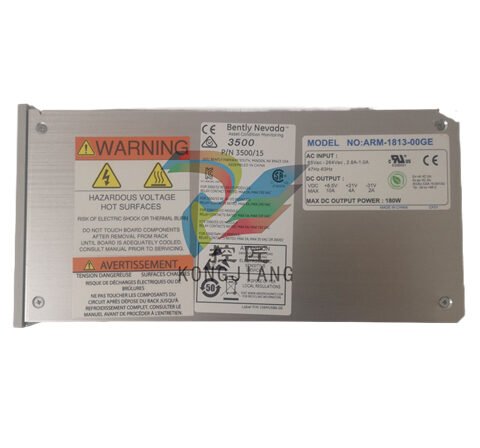

9. **BENTLY 3500/15**: A reliable solution for essential machinery monitoring.

10. **BENTLY 3500/77M**: An advanced model that focuses on multi-channel monitoring for critical applications.

Conclusion

The BENTLY Nevada represents a leap forward in condition monitoring and machinery protection, making it an essential component for businesses looking to optimize performance and reliability. Its advanced technical features, combined with versatile usage scenarios and a comprehensive suite of related models, position the BENTLY Nevada as a leader in the field of industrial automation. By investing in the BENTLY Nevada, companies can ensure their machinery operates at peak efficiency, ultimately driving productivity and profitability in an increasingly competitive landscape.

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY Nevada series, renowned for its precision and reliability, is at the forefront of industrial automation and condition monitoring. The BENTLY Nevada model exemplifies cutting-edge technology through its innovative design and robust features, making it an invaluable asset for industries that demand unwavering performance and operational efficiency.

Key Technical Features

The BENTLY Nevada is engineered with a suite of advanced features that set it apart from conventional monitoring systems. At its core, this model integrates advanced vibration monitoring capabilities, enabling real-time assessments of machinery health. Key features include:

1. **High-Precision Sensors**: The BENTLY Nevada utilizes state-of-the-art vibration sensors, which deliver accurate data on machine performance and health. This enables early detection of potential issues, allowing for timely intervention and minimized downtime.

2. **Multi-Channel Capability**: With the ability to monitor multiple channels simultaneously, the BENTLY Nevada allows for comprehensive analysis of various machinery elements, making it ideal for complex industrial environments.

3. **Robust Data Processing**: Equipped with sophisticated algorithms, the BENTLY Nevada processes vast amounts of data quickly and efficiently. This ensures that operators receive actionable insights in real-time, facilitating proactive maintenance strategies.

4. **User-Friendly Interface**: The intuitive interface of the BENTLY Nevada simplifies operation and monitoring. The graphical displays and easy navigation empower users to access critical information without extensive training.

5. **Integration with BENTLY Automation Products**: Designed to seamlessly integrate with other BENTLY automation products, the Nevada model enhances overall system performance. This interoperability enables users to create a comprehensive monitoring solution tailored to specific operational requirements.

Usage Scenarios

The BENTLY Nevada is ideally suited for a variety of industrial applications, including but not limited to:

– **Power Generation**: In power plants, the BENTLY Nevada monitors rotating equipment such as turbines and generators. By ensuring optimal performance, it helps prevent catastrophic failures that could result in costly outages.

– **Oil and Gas**: In the oil and gas sector, the BENTLY Nevada is critical for monitoring pumps, compressors, and other vital machinery. Its early warning capabilities are essential for maintaining operational integrity and safety in high-risk environments.

– **Manufacturing**: In manufacturing facilities, the BENTLY Nevada provides real-time insights into the health of production equipment. By identifying issues before they escalate, companies can enhance productivity and reduce maintenance costs.

– **Mining and Metals**: The harsh conditions found in mining and metals operations make the BENTLY Nevada an ideal choice for monitoring heavy machinery. Its durability ensures reliable performance even in the most challenging environments.

Comparison with Other Models

When comparing the BENTLY Nevada with other models in the BENTLY lineup, its unique features and capabilities come to light. For example:

– **BENTLY 3500 Series**: While the BENTLY 3500 series offers robust monitoring capabilities, the BENTLY Nevada enhances these features with improved data processing and user interface design, making it easier for operators to gain insights.

– **BENTLY 3300 Series**: The BENTLY 3300 series focuses primarily on vibration monitoring, but the BENTLY Nevada expands on this by incorporating multi-channel capabilities and advanced analytics, catering to more complex industrial applications.

– **BENTLY 3500/40M**: Although the BENTLY 3500/40M provides exceptional machinery protection, the BENTLY Nevada's superior sensor technology and integration options position it as the more advanced choice for modern automation needs.

Related Models

The BENTLY Nevada is part of a comprehensive family of products designed for various monitoring and automation needs. Some related models include:

1. **BENTLY 3500/20 125744-02**: A versatile monitoring solution ideal for various industrial applications.

2. **BENTLY 3500/45 176449-04**: Known for its reliability in monitoring rotating machinery.

3. **BENTLY 60M100-00**: A specialized model designed for specific automation scenarios.

4. **BENTLY 3500/34**: This model focuses on critical machinery monitoring and protection.

5. **BENTLY 3500/42M**: Offers enhanced protection features for machinery in high-stakes environments.

6. **BENTLY 330500-00-00**: A robust choice for overall equipment health monitoring.

7. **BENTLY 3500/50**: Provides comprehensive monitoring capabilities for various applications.

8. **BENTLY 3500/53**: Tailored for advanced condition monitoring in complex systems.

9. **BENTLY 3500/15**: A reliable solution for essential machinery monitoring.

10. **BENTLY 3500/77M**: An advanced model that focuses on multi-channel monitoring for critical applications.

Conclusion

The BENTLY Nevada represents a leap forward in condition monitoring and machinery protection, making it an essential component for businesses looking to optimize performance and reliability. Its advanced technical features, combined with versatile usage scenarios and a comprehensive suite of related models, position the BENTLY Nevada as a leader in the field of industrial automation. By investing in the BENTLY Nevada, companies can ensure their machinery operates at peak efficiency, ultimately driving productivity and profitability in an increasingly competitive landscape.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.