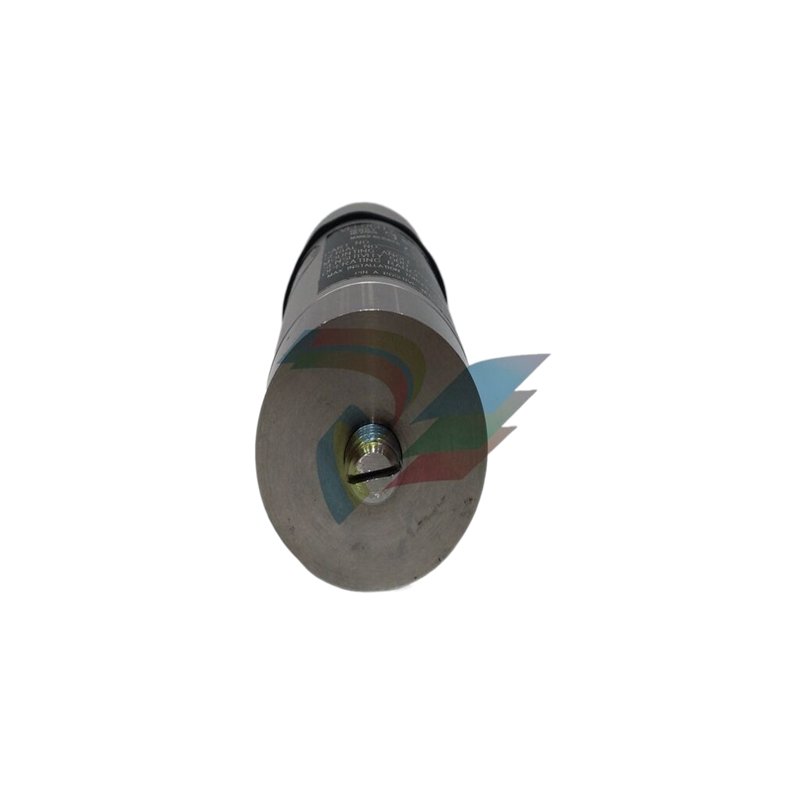

BENTLY Nevada 3300 XL Proximity Probes, 11 mm Module, Fine Detail

Introducing the BENTLY Nevada: Elevating Performance in Condition Monitoring

The BENTLY Nevada is a critical component in the landscape of industrial automation, renowned for its precision and reliability in condition monitoring. As part of the esteemed BENTLY automation products family, this model is designed to provide unparalleled insights into machinery health, ensuring optimum performance and longevity. With advanced features tailored for a variety of industrial applications, the BENTLY Nevada stands out as a premier choice for businesses seeking to enhance their operational efficiency.

Key Technical Features

The BENTLY Nevada is equipped with cutting-edge technology that sets it apart from its competitors. Some of its key technical features include:

1. **Real-Time Monitoring**: The BENTLY Nevada offers real-time data acquisition, allowing users to monitor critical parameters such as vibration, temperature, and pressure. This feature ensures immediate detection of anomalies, facilitating proactive maintenance.

2. **Multi-Channel Capability**: With the ability to support multiple channels, the BENTLY Nevada can monitor various machines simultaneously. This scalability makes it an ideal solution for complex industrial environments with numerous assets.

3. **Robust Data Analysis**: Advanced analytical tools are integrated into the BENTLY Nevada, enabling users to conduct in-depth analyses of machinery performance. The system provides valuable insights through trend analysis, spectral analysis, and fault diagnosis, helping to identify potential issues before they escalate.

4. **User-Friendly Interface**: The BENTLY Nevada features an intuitive interface, making it easy for operators to navigate and interpret data. Customizable dashboards allow users to tailor their monitoring experience to meet specific operational needs.

5. **Durability and Reliability**: Built to withstand harsh industrial conditions, the BENTLY Nevada is designed for longevity. Its rugged construction ensures reliable performance even in the most demanding environments.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide range of applications across various industries. Some common usage scenarios include:

1. **Power Generation**: In power plants, the BENTLY Nevada monitors turbines, generators, and other critical equipment, ensuring they operate efficiently and safely.

2. **Oil and Gas**: The oil and gas industry relies on the BENTLY Nevada to monitor drilling rigs and production facilities, where early detection of potential failures can prevent costly downtimes and ensure safety.

3. **Manufacturing**: In manufacturing settings, the BENTLY Nevada is used to monitor rotating equipment, such as motors and pumps, allowing for optimized maintenance schedules and reduced unplanned shutdowns.

4. **Water and Wastewater Treatment**: The BENTLY Nevada helps maintain the health of pumps and blowers in water treatment facilities, ensuring that operations run smoothly and comply with regulatory standards.

5. **Mining**: In mining operations, the BENTLY Nevada is essential for monitoring heavy machinery, providing insights that can enhance productivity and reduce operational risks.

Comparison with Other Models

When comparing the BENTLY Nevada to other models within the BENTLY family, several differentiators emerge:

– **BENTLY 3500/20**: While the BENTLY 3500/20 focuses primarily on vibration monitoring, the BENTLY Nevada offers a more comprehensive suite of features that includes temperature and pressure monitoring, making it a more versatile choice for condition monitoring.

– **BENTLY 3500/40M**: The BENTLY 3500/40M is geared towards machinery protection, whereas the BENTLY Nevada emphasizes predictive analytics and real-time data acquisition, providing deeper insights into machinery health.

– **BENTLY 3300 Series**: The BENTLY 3300 series is designed for specific monitoring tasks, such as vibration and displacement. In contrast, the BENTLY Nevada combines these capabilities with advanced data analytics, making it a more holistic solution for condition monitoring.

– **BENTLY 3500/50**: While both models are robust, the BENTLY Nevada’s enhanced user interface and multi-channel capability set it apart, allowing for more streamlined monitoring of multiple assets.

– **BENTLY 3500/92**: The BENTLY 3500/92 excels in specific applications, but the BENTLY Nevada’s broader range of monitoring capabilities makes it a more adaptable option for diverse industrial environments.

Reference to Related Models

To provide a comprehensive understanding of the BENTLY Nevada's position within the BENTLY product lineup, here are ten related models:

1. BENTLY 3500/20 125744-02

2. BENTLY 3500/45 176449-04

3. BENTLY 3500/34

4. BENTLY 3500/42M

5. BENTLY 3500/40M

6. BENTLY 3500/50

7. BENTLY 3500/53

8. BENTLY 3500/64M

9. BENTLY 3500/15

10. BENTLY 3500/25-01-00-00

Conclusion

The BENTLY Nevada stands as a benchmark in the realm of condition monitoring, offering advanced features that cater to a multitude of industries. Its ability to provide real-time insights into machinery performance, coupled with its durability and user-friendly interface, makes it an invaluable tool for businesses looking to enhance operational efficiency and reduce downtime. By choosing the BENTLY Nevada, organizations invest in a future of increased reliability and performance, solidifying their commitment to operational excellence. Elevate your condition monitoring strategy today with the trusted name in industrial automation—BENTLY Nevada.

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY Nevada is a critical component in the landscape of industrial automation, renowned for its precision and reliability in condition monitoring. As part of the esteemed BENTLY automation products family, this model is designed to provide unparalleled insights into machinery health, ensuring optimum performance and longevity. With advanced features tailored for a variety of industrial applications, the BENTLY Nevada stands out as a premier choice for businesses seeking to enhance their operational efficiency.

Key Technical Features

The BENTLY Nevada is equipped with cutting-edge technology that sets it apart from its competitors. Some of its key technical features include:

1. **Real-Time Monitoring**: The BENTLY Nevada offers real-time data acquisition, allowing users to monitor critical parameters such as vibration, temperature, and pressure. This feature ensures immediate detection of anomalies, facilitating proactive maintenance.

2. **Multi-Channel Capability**: With the ability to support multiple channels, the BENTLY Nevada can monitor various machines simultaneously. This scalability makes it an ideal solution for complex industrial environments with numerous assets.

3. **Robust Data Analysis**: Advanced analytical tools are integrated into the BENTLY Nevada, enabling users to conduct in-depth analyses of machinery performance. The system provides valuable insights through trend analysis, spectral analysis, and fault diagnosis, helping to identify potential issues before they escalate.

4. **User-Friendly Interface**: The BENTLY Nevada features an intuitive interface, making it easy for operators to navigate and interpret data. Customizable dashboards allow users to tailor their monitoring experience to meet specific operational needs.

5. **Durability and Reliability**: Built to withstand harsh industrial conditions, the BENTLY Nevada is designed for longevity. Its rugged construction ensures reliable performance even in the most demanding environments.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide range of applications across various industries. Some common usage scenarios include:

1. **Power Generation**: In power plants, the BENTLY Nevada monitors turbines, generators, and other critical equipment, ensuring they operate efficiently and safely.

2. **Oil and Gas**: The oil and gas industry relies on the BENTLY Nevada to monitor drilling rigs and production facilities, where early detection of potential failures can prevent costly downtimes and ensure safety.

3. **Manufacturing**: In manufacturing settings, the BENTLY Nevada is used to monitor rotating equipment, such as motors and pumps, allowing for optimized maintenance schedules and reduced unplanned shutdowns.

4. **Water and Wastewater Treatment**: The BENTLY Nevada helps maintain the health of pumps and blowers in water treatment facilities, ensuring that operations run smoothly and comply with regulatory standards.

5. **Mining**: In mining operations, the BENTLY Nevada is essential for monitoring heavy machinery, providing insights that can enhance productivity and reduce operational risks.

Comparison with Other Models

When comparing the BENTLY Nevada to other models within the BENTLY family, several differentiators emerge:

– **BENTLY 3500/20**: While the BENTLY 3500/20 focuses primarily on vibration monitoring, the BENTLY Nevada offers a more comprehensive suite of features that includes temperature and pressure monitoring, making it a more versatile choice for condition monitoring.

– **BENTLY 3500/40M**: The BENTLY 3500/40M is geared towards machinery protection, whereas the BENTLY Nevada emphasizes predictive analytics and real-time data acquisition, providing deeper insights into machinery health.

– **BENTLY 3300 Series**: The BENTLY 3300 series is designed for specific monitoring tasks, such as vibration and displacement. In contrast, the BENTLY Nevada combines these capabilities with advanced data analytics, making it a more holistic solution for condition monitoring.

– **BENTLY 3500/50**: While both models are robust, the BENTLY Nevada’s enhanced user interface and multi-channel capability set it apart, allowing for more streamlined monitoring of multiple assets.

– **BENTLY 3500/92**: The BENTLY 3500/92 excels in specific applications, but the BENTLY Nevada’s broader range of monitoring capabilities makes it a more adaptable option for diverse industrial environments.

Reference to Related Models

To provide a comprehensive understanding of the BENTLY Nevada's position within the BENTLY product lineup, here are ten related models:

1. BENTLY 3500/20 125744-02

2. BENTLY 3500/45 176449-04

3. BENTLY 3500/34

4. BENTLY 3500/42M

5. BENTLY 3500/40M

6. BENTLY 3500/50

7. BENTLY 3500/53

8. BENTLY 3500/64M

9. BENTLY 3500/15

10. BENTLY 3500/25-01-00-00

Conclusion

The BENTLY Nevada stands as a benchmark in the realm of condition monitoring, offering advanced features that cater to a multitude of industries. Its ability to provide real-time insights into machinery performance, coupled with its durability and user-friendly interface, makes it an invaluable tool for businesses looking to enhance operational efficiency and reduce downtime. By choosing the BENTLY Nevada, organizations invest in a future of increased reliability and performance, solidifying their commitment to operational excellence. Elevate your condition monitoring strategy today with the trusted name in industrial automation—BENTLY Nevada.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.