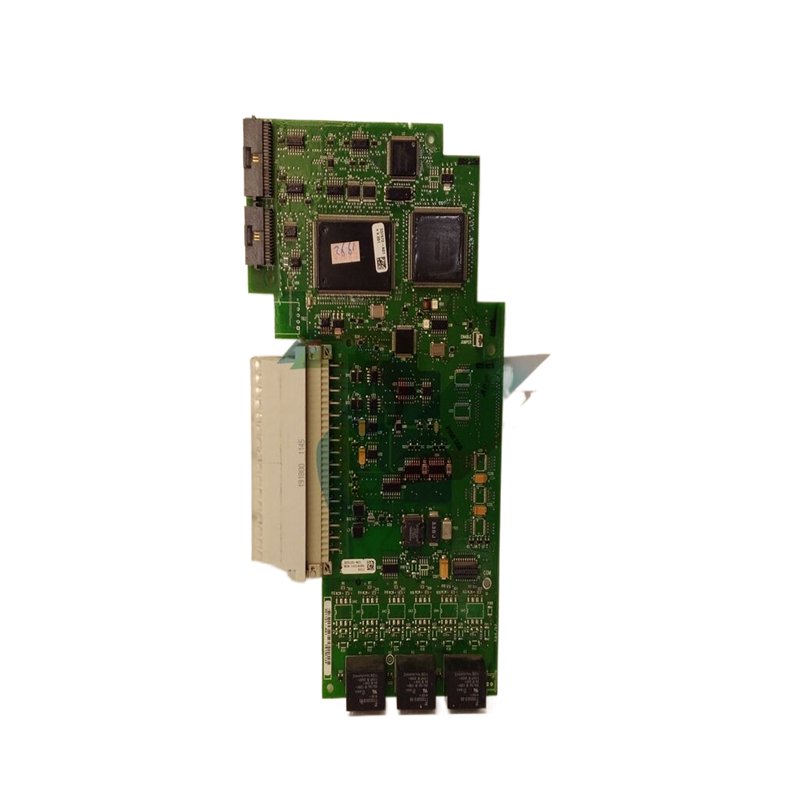

BENTLY Nevada 330103-00-09-10-02-00 Proximity Probes, 3300 XL 8 mm, Industrial Automation Solutions

Introducing the BENTLY Nevada—a pinnacle of reliability and precision in the realm of condition monitoring and predictive maintenance. Renowned for its robust design and advanced capabilities, the BENTLY Nevada is a cornerstone of BENTLY automation products, engineered to enhance operational efficiency across various industrial applications.

Key Technical Features

The BENTLY Nevada stands out with its comprehensive suite of features designed for optimal performance. Key technical specifications include:

1. **Advanced Monitoring Capabilities**: Equipped with high-fidelity sensors and data acquisition systems, the BENTLY Nevada provides real-time insights into the operational health of machinery. It monitors vibration, temperature, and other critical parameters, ensuring that potential issues are detected before they escalate.

2. **Scalability**: The BENTLY Nevada is designed to accommodate a wide range of monitoring applications. Its modular architecture allows for easy expansion and integration into existing systems, making it suitable for both small-scale operations and large industrial enterprises.

3. **User-Friendly Interface**: The intuitive user interface simplifies the monitoring process, allowing operators to quickly access critical information. This design minimizes the learning curve and increases operational efficiency.

4. **Robust Data Analysis Tools**: The BENTLY Nevada comes equipped with sophisticated data analysis tools that facilitate trend analysis, anomaly detection, and predictive maintenance strategies. This proactive approach helps reduce downtime and maintenance costs.

5. **Durability and Reliability**: Built to withstand harsh industrial environments, the BENTLY Nevada features rugged construction and high tolerance to extreme temperatures, humidity, and vibration, ensuring consistent performance in demanding settings.

Usage Scenarios

The BENTLY Nevada is widely used across various sectors, including:

1. **Oil and Gas**: In the oil and gas industry, the BENTLY Nevada plays a crucial role in monitoring drilling rigs, pipelines, and refineries, where equipment reliability is paramount to both safety and productivity.

2. **Manufacturing**: In manufacturing plants, the BENTLY Nevada monitors critical machinery such as turbines, compressors, and conveyor systems, ensuring optimal performance and minimizing unexpected failures.

3. **Power Generation**: Power plants utilize the BENTLY Nevada to oversee the health of generators and turbines, enabling operators to implement maintenance strategies that enhance efficiency and reliability.

4. **Transportation**: In the transportation sector, the BENTLY Nevada is employed to monitor the condition of locomotives and other critical transport machinery, ensuring safe and efficient operations.

5. **Mining**: The rugged design of the BENTLY Nevada makes it ideal for monitoring equipment in mining operations, where exposure to dust, moisture, and extreme conditions is a daily challenge.

Comparison with Other Models

When compared to other models within the BENTLY range, the BENTLY Nevada distinguishes itself with enhanced monitoring capabilities and customizable features. For instance, while the **BENTLY 3500/20 125744-02** offers robust condition monitoring, the BENTLY Nevada takes it a step further with its advanced data analysis and user-friendly interface.

Similarly, while models like the **BENTLY 3500/50** and **BENTLY 3500/34** are excellent for specific applications, the BENTLY Nevada’s versatility allows it to excel across a broader range of scenarios. The BENTLY Nevada is also more adaptable than the **BENTLY 3300/16**, making it a superior choice for facilities looking to future-proof their monitoring systems.

Related Models

To provide a comprehensive understanding of options within the BENTLY family, here are ten related models that share similarities with the BENTLY Nevada, each catering to specific needs:

1. **BENTLY 3500/45 176449-04**: Known for its vibration monitoring capabilities, this model is ideal for rotating machinery.

2. **BENTLY 3500/40M**: A compact model suitable for monitoring machinery in confined spaces.

3. **BENTLY 3500/53**: This model excels in advanced vibration analysis, providing deeper insights into equipment health.

4. **BENTLY 3500/22M**: Designed for temperature monitoring, it integrates seamlessly with the BENTLY Nevada.

5. **BENTLY 330500-00-00**: A reliable model for simpler monitoring tasks, perfect for organizations starting their predictive maintenance journey.

6. **BENTLY 3500/50**: Offers a more basic level of monitoring while still maintaining high reliability.

7. **BENTLY 3500/15**: A cost-effective option for companies focused on basic vibration analysis.

8. **BENTLY 3500/92**: Provides advanced diagnostics for specific machinery segments.

9. **BENTLY 3500/72M**: Tailored for high-precision applications where detailed analysis is critical.

10. **BENTLY 3500/40M 176449-01**: This variant offers additional features suitable for specialized environments.

In conclusion, the BENTLY Nevada stands as a formidable choice among BENTLY automation products, setting a benchmark for performance, reliability, and adaptability in various industrial applications. With its advanced monitoring capabilities and user-focused design, the BENTLY Nevada empowers organizations to enhance operational efficiency, reduce downtime, and implement effective maintenance strategies. Whether in oil and gas, manufacturing, power generation, transportation, or mining, the BENTLY Nevada is engineered to meet and exceed the demands of modern industry. Invest in the BENTLY Nevada today and unlock a new level of operational excellence.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada stands out with its comprehensive suite of features designed for optimal performance. Key technical specifications include:

1. **Advanced Monitoring Capabilities**: Equipped with high-fidelity sensors and data acquisition systems, the BENTLY Nevada provides real-time insights into the operational health of machinery. It monitors vibration, temperature, and other critical parameters, ensuring that potential issues are detected before they escalate.

2. **Scalability**: The BENTLY Nevada is designed to accommodate a wide range of monitoring applications. Its modular architecture allows for easy expansion and integration into existing systems, making it suitable for both small-scale operations and large industrial enterprises.

3. **User-Friendly Interface**: The intuitive user interface simplifies the monitoring process, allowing operators to quickly access critical information. This design minimizes the learning curve and increases operational efficiency.

4. **Robust Data Analysis Tools**: The BENTLY Nevada comes equipped with sophisticated data analysis tools that facilitate trend analysis, anomaly detection, and predictive maintenance strategies. This proactive approach helps reduce downtime and maintenance costs.

5. **Durability and Reliability**: Built to withstand harsh industrial environments, the BENTLY Nevada features rugged construction and high tolerance to extreme temperatures, humidity, and vibration, ensuring consistent performance in demanding settings.

Usage Scenarios

The BENTLY Nevada is widely used across various sectors, including:

1. **Oil and Gas**: In the oil and gas industry, the BENTLY Nevada plays a crucial role in monitoring drilling rigs, pipelines, and refineries, where equipment reliability is paramount to both safety and productivity.

2. **Manufacturing**: In manufacturing plants, the BENTLY Nevada monitors critical machinery such as turbines, compressors, and conveyor systems, ensuring optimal performance and minimizing unexpected failures.

3. **Power Generation**: Power plants utilize the BENTLY Nevada to oversee the health of generators and turbines, enabling operators to implement maintenance strategies that enhance efficiency and reliability.

4. **Transportation**: In the transportation sector, the BENTLY Nevada is employed to monitor the condition of locomotives and other critical transport machinery, ensuring safe and efficient operations.

5. **Mining**: The rugged design of the BENTLY Nevada makes it ideal for monitoring equipment in mining operations, where exposure to dust, moisture, and extreme conditions is a daily challenge.

Comparison with Other Models

When compared to other models within the BENTLY range, the BENTLY Nevada distinguishes itself with enhanced monitoring capabilities and customizable features. For instance, while the **BENTLY 3500/20 125744-02** offers robust condition monitoring, the BENTLY Nevada takes it a step further with its advanced data analysis and user-friendly interface.

Similarly, while models like the **BENTLY 3500/50** and **BENTLY 3500/34** are excellent for specific applications, the BENTLY Nevada’s versatility allows it to excel across a broader range of scenarios. The BENTLY Nevada is also more adaptable than the **BENTLY 3300/16**, making it a superior choice for facilities looking to future-proof their monitoring systems.

Related Models

To provide a comprehensive understanding of options within the BENTLY family, here are ten related models that share similarities with the BENTLY Nevada, each catering to specific needs:

1. **BENTLY 3500/45 176449-04**: Known for its vibration monitoring capabilities, this model is ideal for rotating machinery.

2. **BENTLY 3500/40M**: A compact model suitable for monitoring machinery in confined spaces.

3. **BENTLY 3500/53**: This model excels in advanced vibration analysis, providing deeper insights into equipment health.

4. **BENTLY 3500/22M**: Designed for temperature monitoring, it integrates seamlessly with the BENTLY Nevada.

5. **BENTLY 330500-00-00**: A reliable model for simpler monitoring tasks, perfect for organizations starting their predictive maintenance journey.

6. **BENTLY 3500/50**: Offers a more basic level of monitoring while still maintaining high reliability.

7. **BENTLY 3500/15**: A cost-effective option for companies focused on basic vibration analysis.

8. **BENTLY 3500/92**: Provides advanced diagnostics for specific machinery segments.

9. **BENTLY 3500/72M**: Tailored for high-precision applications where detailed analysis is critical.

10. **BENTLY 3500/40M 176449-01**: This variant offers additional features suitable for specialized environments.

In conclusion, the BENTLY Nevada stands as a formidable choice among BENTLY automation products, setting a benchmark for performance, reliability, and adaptability in various industrial applications. With its advanced monitoring capabilities and user-focused design, the BENTLY Nevada empowers organizations to enhance operational efficiency, reduce downtime, and implement effective maintenance strategies. Whether in oil and gas, manufacturing, power generation, transportation, or mining, the BENTLY Nevada is engineered to meet and exceed the demands of modern industry. Invest in the BENTLY Nevada today and unlock a new level of operational excellence.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.