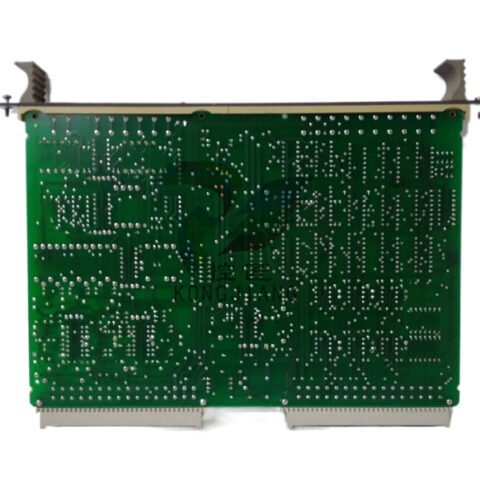

ABB BRC300 Controller Module for Industrial Automation

Introducing the ABB BRC300: The Pinnacle of Precision and Performance in ABB Automation Products

The ABB BRC300 stands out as a remarkable entry in ABB's comprehensive suite of automation products. Designed for the most demanding industrial applications, the BRC300 is engineered to provide superior control, accuracy, and reliability. This product embodies ABB's commitment to innovation, making it an ideal choice for businesses seeking to enhance their operations.

Key Technical Features

At the heart of the ABB BRC300 are its advanced technical features that ensure optimal performance across various applications. The device boasts a robust processing unit that allows for high-speed data processing, enabling real-time monitoring and control. With a user-friendly interface, operators can easily navigate through settings, making adjustments swiftly without compromising on safety or efficiency.

The BRC300 supports a wide range of communication protocols, including Ethernet/IP, Modbus TCP, and CANopen, allowing seamless integration with existing systems. This versatility is complemented by its modular design, which enables easy expansion and customization according to specific operational needs.

In terms of environmental resilience, the ABB BRC300 is designed to withstand harsh industrial conditions. It features a rugged housing that protects it from dust and moisture, ensuring reliable operation even in challenging environments. Additionally, the device is equipped with advanced diagnostic tools that provide real-time feedback on operational status, thereby minimizing downtime and maintenance costs.

Usage Scenarios

The ABB BRC300 is versatile enough to be utilized in a multitude of settings. Whether in manufacturing, process control, or energy management, this device is poised to enhance automation efficiency. For instance, in a manufacturing facility, the BRC300 can be used to control robotic arms and conveyor systems, ensuring precision in assembly lines.

In process control scenarios, its ability to interface with various sensors and actuators makes it ideal for monitoring and regulating parameters such as temperature, pressure, and flow rates. This functionality is crucial in industries such as oil and gas, where maintaining optimal conditions is vital for safety and efficiency.

Furthermore, the ABB BRC300 is well-suited for energy management applications. By integrating with smart grids and renewable energy sources, it can facilitate real-time data analysis and control, helping organizations optimize energy consumption and reduce costs.

Comparison with Other Models

When comparing the ABB BRC300 with other models in ABB’s lineup, such as the ABB DI810 and ABB CI868K01-eA, it becomes clear that the BRC300 offers enhanced capabilities. While the DI810 is excellent for digital input processing, it lacks the comprehensive communication support of the BRC300. Similarly, the CI868K01-eA may excel in specific applications but does not provide the same level of versatility and adaptability that the BRC300 does.

Another notable comparison can be made with the ABB PM861K01. While both devices are designed for automation, the BRC300’s modular design and advanced diagnostic features provide a distinct advantage for users seeking a highly customizable and efficient solution. In industries requiring sophisticated control mechanisms, the BRC300 outperforms models like the ABB 12KM02E-V0002, which may be limited in communication options.

Moreover, compared to the ABB PFSK164, the BRC300 offers superior processing speed and flexibility, making it the preferred choice for organizations looking to future-proof their automation systems.

Related Models

To provide a comprehensive understanding of where the ABB BRC300 fits within the broader ABB automation products portfolio, we can reference several related models:

1. ABB DI810 – Digital input module designed for various input configurations.

2. ABB PM861K01 3BSE018105R1 – A powerful process automation controller.

3. ABB CI868K01-eA – A communication interface for various field devices.

4. ABB 12KM02E-V0002 – A noteworthy controller for specific automation tasks.

5. ABB PFSK164 3BSE021180R1 – A compact field controller with limited customization.

6. ABB UFC719AE101 3BHB003041R0101 – A versatile field unit for automation applications.

7. ABB SCYC51040 – A communication device designed for high-speed data connections.

8. ABB 5SHY6545L0001 AC10272001R0101 – An AC drive well-suited for motor control.

9. ABB RXIDK 1MRK000838-HA – A robust I/O module for real-time data acquisition.

10. ABB DAPI100 3AST000929R109 – A digital automation processor for complex tasks.

Each of these models plays a crucial role in ABB's extensive automation offerings, but the ABB BRC300 truly shines with its comprehensive features and adaptability.

Conclusion

In a landscape where precision, reliability, and efficiency are paramount, the ABB BRC300 emerges as a top-tier choice among ABB automation products. Its advanced technical features, versatility in usage scenarios, and superior performance compared to other models make it an invaluable asset for industries striving for operational excellence. By choosing the ABB BRC300, businesses can not only streamline their processes but also position themselves at the forefront of automation innovation. Invest in the ABB BRC300 today and unlock the full potential of your automation capabilities.

The above parameters are for reference only. Please contact our technical team for precise selection.

The ABB BRC300 stands out as a remarkable entry in ABB's comprehensive suite of automation products. Designed for the most demanding industrial applications, the BRC300 is engineered to provide superior control, accuracy, and reliability. This product embodies ABB's commitment to innovation, making it an ideal choice for businesses seeking to enhance their operations.

Key Technical Features

At the heart of the ABB BRC300 are its advanced technical features that ensure optimal performance across various applications. The device boasts a robust processing unit that allows for high-speed data processing, enabling real-time monitoring and control. With a user-friendly interface, operators can easily navigate through settings, making adjustments swiftly without compromising on safety or efficiency.

The BRC300 supports a wide range of communication protocols, including Ethernet/IP, Modbus TCP, and CANopen, allowing seamless integration with existing systems. This versatility is complemented by its modular design, which enables easy expansion and customization according to specific operational needs.

In terms of environmental resilience, the ABB BRC300 is designed to withstand harsh industrial conditions. It features a rugged housing that protects it from dust and moisture, ensuring reliable operation even in challenging environments. Additionally, the device is equipped with advanced diagnostic tools that provide real-time feedback on operational status, thereby minimizing downtime and maintenance costs.

Usage Scenarios

The ABB BRC300 is versatile enough to be utilized in a multitude of settings. Whether in manufacturing, process control, or energy management, this device is poised to enhance automation efficiency. For instance, in a manufacturing facility, the BRC300 can be used to control robotic arms and conveyor systems, ensuring precision in assembly lines.

In process control scenarios, its ability to interface with various sensors and actuators makes it ideal for monitoring and regulating parameters such as temperature, pressure, and flow rates. This functionality is crucial in industries such as oil and gas, where maintaining optimal conditions is vital for safety and efficiency.

Furthermore, the ABB BRC300 is well-suited for energy management applications. By integrating with smart grids and renewable energy sources, it can facilitate real-time data analysis and control, helping organizations optimize energy consumption and reduce costs.

Comparison with Other Models

When comparing the ABB BRC300 with other models in ABB’s lineup, such as the ABB DI810 and ABB CI868K01-eA, it becomes clear that the BRC300 offers enhanced capabilities. While the DI810 is excellent for digital input processing, it lacks the comprehensive communication support of the BRC300. Similarly, the CI868K01-eA may excel in specific applications but does not provide the same level of versatility and adaptability that the BRC300 does.

Another notable comparison can be made with the ABB PM861K01. While both devices are designed for automation, the BRC300’s modular design and advanced diagnostic features provide a distinct advantage for users seeking a highly customizable and efficient solution. In industries requiring sophisticated control mechanisms, the BRC300 outperforms models like the ABB 12KM02E-V0002, which may be limited in communication options.

Moreover, compared to the ABB PFSK164, the BRC300 offers superior processing speed and flexibility, making it the preferred choice for organizations looking to future-proof their automation systems.

Related Models

To provide a comprehensive understanding of where the ABB BRC300 fits within the broader ABB automation products portfolio, we can reference several related models:

1. ABB DI810 – Digital input module designed for various input configurations.

2. ABB PM861K01 3BSE018105R1 – A powerful process automation controller.

3. ABB CI868K01-eA – A communication interface for various field devices.

4. ABB 12KM02E-V0002 – A noteworthy controller for specific automation tasks.

5. ABB PFSK164 3BSE021180R1 – A compact field controller with limited customization.

6. ABB UFC719AE101 3BHB003041R0101 – A versatile field unit for automation applications.

7. ABB SCYC51040 – A communication device designed for high-speed data connections.

8. ABB 5SHY6545L0001 AC10272001R0101 – An AC drive well-suited for motor control.

9. ABB RXIDK 1MRK000838-HA – A robust I/O module for real-time data acquisition.

10. ABB DAPI100 3AST000929R109 – A digital automation processor for complex tasks.

Each of these models plays a crucial role in ABB's extensive automation offerings, but the ABB BRC300 truly shines with its comprehensive features and adaptability.

Conclusion

In a landscape where precision, reliability, and efficiency are paramount, the ABB BRC300 emerges as a top-tier choice among ABB automation products. Its advanced technical features, versatility in usage scenarios, and superior performance compared to other models make it an invaluable asset for industries striving for operational excellence. By choosing the ABB BRC300, businesses can not only streamline their processes but also position themselves at the forefront of automation innovation. Invest in the ABB BRC300 today and unlock the full potential of your automation capabilities.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.