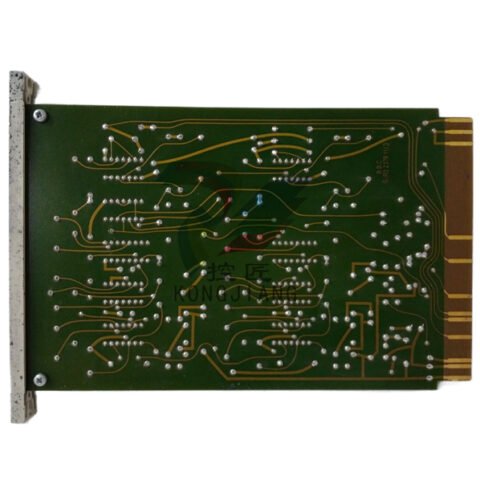

ABB 1602-6K1C2 Inverter – High Efficiency Drives for Industry

Introducing the ABB 1602-6K1C2, a cutting-edge solution in the realm of ABB automation products. This model is engineered to meet the demands of modern industrial applications, providing superior performance, reliability, and versatility.

Key Technical Features

The ABB 1602-6K1C2 is designed with a robust architecture that ensures high efficiency and operational excellence. A standout feature is its advanced processing capability, which allows for seamless integration in various automation systems. It supports a wide range of communication protocols, making it compatible with other ABB devices and third-party equipment. This model is equipped with multiple I/O options, enhancing its adaptability to different automation needs.

One of the critical aspects of the ABB 1602-6K1C2 is its user-friendly interface, which simplifies programming and monitoring. With built-in diagnostics, users can quickly identify and troubleshoot issues, minimizing downtime. Additionally, the unit is designed for easy installation, allowing for swift deployment in production environments.

The ABB 1602-6K1C2 also boasts excellent environmental resilience, with a robust casing that protects against dust and moisture, making it suitable for use in harsh industrial conditions. Its energy-efficient design not only reduces operational costs but also aligns with sustainability goals, a critical consideration in today's manufacturing landscape.

Usage Scenarios

The versatility of the ABB 1602-6K1C2 makes it suitable for a wide array of applications across various industries. In manufacturing settings, it can be integrated into assembly lines to control robotic arms, facilitating precise and efficient operations. Its ability to handle multiple inputs and outputs makes it ideal for complex machinery that requires real-time monitoring and control.

In the energy sector, the ABB 1602-6K1C2 can be employed in process automation, such as monitoring and controlling power distribution systems. Its compatibility with other ABB automation products allows for a cohesive ecosystem that enhances operational efficiency and reliability.

Food and beverage industries can also benefit from the ABB 1602-6K1C2, where it can be used to manage production lines, ensuring compliance with safety standards while optimizing throughput. The model’s diagnostics capabilities are particularly advantageous in preventing production delays and maintaining quality control.

Comparison with Other Models

When compared to other models within the ABB automation products lineup, such as the ABB UNS1860B-P and ABB TU852, the ABB 1602-6K1C2 stands out in terms of processing power and flexibility. While the UNS1860B-P is tailored for more specific applications, the 1602-6K1C2 offers a broader range of functionality, making it suitable for diverse settings.

In contrast to the ABB TU841, which is designed primarily for I/O management, the ABB 1602-6K1C2 provides a more comprehensive solution that incorporates advanced processing capabilities alongside extensive I/O options. This makes it an ideal choice for industries seeking a multifunctional device that can adapt to evolving automation requirements.

The ABB PM511V16 and ABB PM864AK01 are also noteworthy comparisons; while these models excel in specific areas such as power management, the ABB 1602-6K1C2's versatility ensures it meets a wider array of application needs, making it a more holistic choice for many organizations.

Reference to Related Models

The ABB 1602-6K1C2 can be referenced alongside numerous other models that complement its functionality. These include:

1. ABB UNS1860B-P – a reliable choice for specific automation tasks.

2. ABB PPE100A 3BHE037824R0101 – known for its robust performance in industrial settings.

3. ABB TU852 S800 I/O – ideal for modular input/output applications.

4. ABB YPM106E YT204001-FN – designed for dynamic control applications.

5. ABB 07DC91 – offers dependable solutions for industrial automation.

6. ABB IRB 2600 – a collaborative robot that enhances the capabilities of the 1602-6K1C2 in robotic applications.

7. ABB DSQC352B – a model that provides additional I/O options for complex systems.

8. ABB ACS880-01-246A-3 3ABD00035954-D – a drive solution that can work seamlessly with the 1602-6K1C2 for comprehensive automation.

9. ABB GINT5611C – a gateway for integrating various devices within automation networks.

10. ABB SDCS-PIN-51 – a control solution that can enhance the operational capabilities of the ABB 1602-6K1C2.

Conclusion

The ABB 1602-6K1C2 represents a significant advancement in ABB automation products, offering unparalleled performance and flexibility for a variety of industrial applications. Its robust technical features, versatility in usage scenarios, and competitive edge over other models make it an exceptional choice for organizations looking to optimize their automation processes.

For those in search of an efficient, reliable, and adaptable automation solution, the ABB 1602-6K1C2 is the perfect fit, empowering businesses to achieve their operational goals while maintaining the highest standards of quality and performance. Embrace the future of automation with the ABB 1602-6K1C2 and enhance your production capabilities today.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The ABB 1602-6K1C2 is designed with a robust architecture that ensures high efficiency and operational excellence. A standout feature is its advanced processing capability, which allows for seamless integration in various automation systems. It supports a wide range of communication protocols, making it compatible with other ABB devices and third-party equipment. This model is equipped with multiple I/O options, enhancing its adaptability to different automation needs.

One of the critical aspects of the ABB 1602-6K1C2 is its user-friendly interface, which simplifies programming and monitoring. With built-in diagnostics, users can quickly identify and troubleshoot issues, minimizing downtime. Additionally, the unit is designed for easy installation, allowing for swift deployment in production environments.

The ABB 1602-6K1C2 also boasts excellent environmental resilience, with a robust casing that protects against dust and moisture, making it suitable for use in harsh industrial conditions. Its energy-efficient design not only reduces operational costs but also aligns with sustainability goals, a critical consideration in today's manufacturing landscape.

Usage Scenarios

The versatility of the ABB 1602-6K1C2 makes it suitable for a wide array of applications across various industries. In manufacturing settings, it can be integrated into assembly lines to control robotic arms, facilitating precise and efficient operations. Its ability to handle multiple inputs and outputs makes it ideal for complex machinery that requires real-time monitoring and control.

In the energy sector, the ABB 1602-6K1C2 can be employed in process automation, such as monitoring and controlling power distribution systems. Its compatibility with other ABB automation products allows for a cohesive ecosystem that enhances operational efficiency and reliability.

Food and beverage industries can also benefit from the ABB 1602-6K1C2, where it can be used to manage production lines, ensuring compliance with safety standards while optimizing throughput. The model’s diagnostics capabilities are particularly advantageous in preventing production delays and maintaining quality control.

Comparison with Other Models

When compared to other models within the ABB automation products lineup, such as the ABB UNS1860B-P and ABB TU852, the ABB 1602-6K1C2 stands out in terms of processing power and flexibility. While the UNS1860B-P is tailored for more specific applications, the 1602-6K1C2 offers a broader range of functionality, making it suitable for diverse settings.

In contrast to the ABB TU841, which is designed primarily for I/O management, the ABB 1602-6K1C2 provides a more comprehensive solution that incorporates advanced processing capabilities alongside extensive I/O options. This makes it an ideal choice for industries seeking a multifunctional device that can adapt to evolving automation requirements.

The ABB PM511V16 and ABB PM864AK01 are also noteworthy comparisons; while these models excel in specific areas such as power management, the ABB 1602-6K1C2's versatility ensures it meets a wider array of application needs, making it a more holistic choice for many organizations.

Reference to Related Models

The ABB 1602-6K1C2 can be referenced alongside numerous other models that complement its functionality. These include:

1. ABB UNS1860B-P – a reliable choice for specific automation tasks.

2. ABB PPE100A 3BHE037824R0101 – known for its robust performance in industrial settings.

3. ABB TU852 S800 I/O – ideal for modular input/output applications.

4. ABB YPM106E YT204001-FN – designed for dynamic control applications.

5. ABB 07DC91 – offers dependable solutions for industrial automation.

6. ABB IRB 2600 – a collaborative robot that enhances the capabilities of the 1602-6K1C2 in robotic applications.

7. ABB DSQC352B – a model that provides additional I/O options for complex systems.

8. ABB ACS880-01-246A-3 3ABD00035954-D – a drive solution that can work seamlessly with the 1602-6K1C2 for comprehensive automation.

9. ABB GINT5611C – a gateway for integrating various devices within automation networks.

10. ABB SDCS-PIN-51 – a control solution that can enhance the operational capabilities of the ABB 1602-6K1C2.

Conclusion

The ABB 1602-6K1C2 represents a significant advancement in ABB automation products, offering unparalleled performance and flexibility for a variety of industrial applications. Its robust technical features, versatility in usage scenarios, and competitive edge over other models make it an exceptional choice for organizations looking to optimize their automation processes.

For those in search of an efficient, reliable, and adaptable automation solution, the ABB 1602-6K1C2 is the perfect fit, empowering businesses to achieve their operational goals while maintaining the highest standards of quality and performance. Embrace the future of automation with the ABB 1602-6K1C2 and enhance your production capabilities today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.