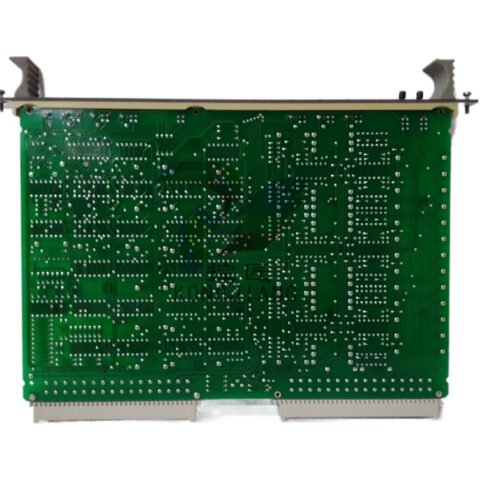

ABB IRB7602-33HAC058991-004 IRC5 DSQC601 3HAC12815-1 Industrial Control Modules

Introducing the ABB IRB7602-33HAC058991-004 IRC5 DSQC601 3HAC12815-1, a cutting-edge industrial robot designed to revolutionize automation in various sectors. As part of ABB’s renowned lineup of automation products, the IRB7602 series stands out with its robust performance, exceptional precision, and versatility.

Key Technical Features

The ABB IRB7602-33HAC058991-004 is powered by the advanced IRC5 controller, which offers unparalleled motion control and real-time performance management. It features a compact design that allows for easy integration into existing workflows, making it ideal for applications requiring high productivity and efficiency. With its 6-axis articulation, the IRB7602 ensures precise movements, enabling it to handle complex tasks with ease.

One of the standout features of this model is its high payload capacity, allowing it to handle loads of up to 33 kg. This makes it suitable for a variety of tasks, from assembly and material handling to welding and packaging. The robot has a reach of 1,650 mm, providing ample flexibility to cover large work areas without the need for repositioning.

The ABB IRB7602 also incorporates advanced safety features such as collaborative operation modes, which enable it to work alongside human operators without the need for extensive safety barriers. This enhances workplace safety while maximizing productivity. Additionally, the robot's energy-efficient design contributes to lower operational costs, making it an economical choice for businesses looking to optimize their automation processes.

Usage Scenarios

The versatility of the ABB IRB7602-33HAC058991-004 makes it a perfect fit for a wide range of industries and applications. In automotive manufacturing, it can be employed for tasks such as assembly, painting, and quality inspection. Its precision ensures that components are assembled accurately, leading to higher-quality end products.

In the electronics sector, the robot can assist in the assembly of delicate components, where precision and care are paramount. Its ability to handle various materials also makes it suitable for packaging applications, where it can automate the packing process, reducing manual labor and increasing efficiency.

Furthermore, the ABB IRB7602 is ideal for the food and beverage industry, where hygiene and precision are critical. It can be used for packaging, sorting, and even palletizing products, ensuring that operations run smoothly and efficiently.

Comparison with Other Models

When comparing the ABB IRB7602-33HAC058991-004 with other models in the ABB portfolio, such as the ABB IRB 2400 and ABB IRB 2600, it becomes evident that the IRB7602 offers superior payload capacity and reach. While the IRB 2400 is renowned for its speed and versatility, the IRB7602 combines these attributes with enhanced payload capabilities, making it a more suitable option for heavy-duty applications.

Additionally, the ABB IRB 2600, known for its compact design, excels in tight spaces. However, the IRB7602's collaborative features and safety measures make it the preferred choice for environments where human-robot interaction is necessary. It strikes a balance between performance and safety, ensuring that operators can work alongside it without compromising productivity.

Related Models

The ABB IRB7602-33HAC058991-004 is part of a broader family of ABB automation products that cater to various industrial needs. Some related models include:

1. ABB IRB 2400 – Known for its speed and reliability in assembly applications.

2. ABB IRB 2600 – A compact robot ideal for tight spaces and high-speed operations.

3. ABB IRB 6700 – Designed for heavy-duty applications with a higher payload capacity.

4. ABB IRB 6700/240 – Offers an extensive reach and is suited for large-scale manufacturing.

5. ABB IRB 8600 – Optimized for larger payloads and longer reach, perfect for heavy lifting.

6. ABB IRB 1600 – A smaller variant suitable for lighter tasks and confined spaces.

7. ABB IRB 5400 – High-speed robot designed for high-volume production lines.

8. ABB IRB 6640 – Balances reach and payload capacity, ideal for diverse applications.

9. ABB IRB 6700-200 – Offers a combination of reach and payload for versatile operations.

10. ABB IRB 6700/155 – A robust option for applications requiring heavy lifting.

Conclusion

The ABB IRB7602-33HAC058991-004 IRC5 DSQC601 3HAC12815-1 represents the pinnacle of robotic automation technology. With its powerful IRC5 controller, impressive payload capacity, and versatile applications, it stands as a leading choice for businesses seeking to enhance their operational efficiency. Its ability to seamlessly integrate into various industries, coupled with advanced safety features, ensures that it meets the demands of modern manufacturing processes.

Whether you are in automotive, electronics, food and beverage, or any other sector, the ABB IRB7602 is designed to elevate your production capabilities. Invest in the future of automation with the ABB IRB7602-33HAC058991-004 and experience unparalleled performance and reliability in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The ABB IRB7602-33HAC058991-004 is powered by the advanced IRC5 controller, which offers unparalleled motion control and real-time performance management. It features a compact design that allows for easy integration into existing workflows, making it ideal for applications requiring high productivity and efficiency. With its 6-axis articulation, the IRB7602 ensures precise movements, enabling it to handle complex tasks with ease.

One of the standout features of this model is its high payload capacity, allowing it to handle loads of up to 33 kg. This makes it suitable for a variety of tasks, from assembly and material handling to welding and packaging. The robot has a reach of 1,650 mm, providing ample flexibility to cover large work areas without the need for repositioning.

The ABB IRB7602 also incorporates advanced safety features such as collaborative operation modes, which enable it to work alongside human operators without the need for extensive safety barriers. This enhances workplace safety while maximizing productivity. Additionally, the robot's energy-efficient design contributes to lower operational costs, making it an economical choice for businesses looking to optimize their automation processes.

Usage Scenarios

The versatility of the ABB IRB7602-33HAC058991-004 makes it a perfect fit for a wide range of industries and applications. In automotive manufacturing, it can be employed for tasks such as assembly, painting, and quality inspection. Its precision ensures that components are assembled accurately, leading to higher-quality end products.

In the electronics sector, the robot can assist in the assembly of delicate components, where precision and care are paramount. Its ability to handle various materials also makes it suitable for packaging applications, where it can automate the packing process, reducing manual labor and increasing efficiency.

Furthermore, the ABB IRB7602 is ideal for the food and beverage industry, where hygiene and precision are critical. It can be used for packaging, sorting, and even palletizing products, ensuring that operations run smoothly and efficiently.

Comparison with Other Models

When comparing the ABB IRB7602-33HAC058991-004 with other models in the ABB portfolio, such as the ABB IRB 2400 and ABB IRB 2600, it becomes evident that the IRB7602 offers superior payload capacity and reach. While the IRB 2400 is renowned for its speed and versatility, the IRB7602 combines these attributes with enhanced payload capabilities, making it a more suitable option for heavy-duty applications.

Additionally, the ABB IRB 2600, known for its compact design, excels in tight spaces. However, the IRB7602's collaborative features and safety measures make it the preferred choice for environments where human-robot interaction is necessary. It strikes a balance between performance and safety, ensuring that operators can work alongside it without compromising productivity.

Related Models

The ABB IRB7602-33HAC058991-004 is part of a broader family of ABB automation products that cater to various industrial needs. Some related models include:

1. ABB IRB 2400 – Known for its speed and reliability in assembly applications.

2. ABB IRB 2600 – A compact robot ideal for tight spaces and high-speed operations.

3. ABB IRB 6700 – Designed for heavy-duty applications with a higher payload capacity.

4. ABB IRB 6700/240 – Offers an extensive reach and is suited for large-scale manufacturing.

5. ABB IRB 8600 – Optimized for larger payloads and longer reach, perfect for heavy lifting.

6. ABB IRB 1600 – A smaller variant suitable for lighter tasks and confined spaces.

7. ABB IRB 5400 – High-speed robot designed for high-volume production lines.

8. ABB IRB 6640 – Balances reach and payload capacity, ideal for diverse applications.

9. ABB IRB 6700-200 – Offers a combination of reach and payload for versatile operations.

10. ABB IRB 6700/155 – A robust option for applications requiring heavy lifting.

Conclusion

The ABB IRB7602-33HAC058991-004 IRC5 DSQC601 3HAC12815-1 represents the pinnacle of robotic automation technology. With its powerful IRC5 controller, impressive payload capacity, and versatile applications, it stands as a leading choice for businesses seeking to enhance their operational efficiency. Its ability to seamlessly integrate into various industries, coupled with advanced safety features, ensures that it meets the demands of modern manufacturing processes.

Whether you are in automotive, electronics, food and beverage, or any other sector, the ABB IRB7602 is designed to elevate your production capabilities. Invest in the future of automation with the ABB IRB7602-33HAC058991-004 and experience unparalleled performance and reliability in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.