ABB ACS1000 BASE Object Control & I/O System for Industrial Automation

Introducing the ABB ACS1000 BASE Object, a cutting-edge solution designed to enhance the flexibility and efficiency of your automation systems. As part of ABB's extensive portfolio of automation products, the ACS1000 BASE Object offers a robust foundation for various applications across industries, from manufacturing to energy.

Key Technical Features

The ABB ACS1000 BASE Object is engineered with advanced technology, ensuring optimal performance and reliability. Key features include:

1. **Modular Design**: The ACS1000 is built on a modular architecture, allowing for easy customization and scalability. Users can adapt the system to meet specific application requirements, making it suitable for a wide range of environments.

2. **High Efficiency**: With a power factor close to unity and minimal harmonic distortion, the ABB ACS1000 BASE Object ensures high energy efficiency, reducing operational costs and minimizing environmental impact.

3. **Flexible Control Options**: The system supports various control strategies, including vector control and direct torque control, providing superior performance in speed and torque management. This flexibility makes it ideal for applications ranging from simple pump control to complex motion control tasks.

4. **Advanced Communication Protocols**: The ACS1000 is equipped with multiple communication protocols, including Ethernet/IP and Modbus TCP, enabling seamless integration with existing systems and easy data exchange across the network. This feature enhances interoperability with other ABB automation products and third-party devices.

5. **Robust Protection Features**: Designed to withstand harsh conditions, the ACS1000 incorporates various protection mechanisms, including overcurrent, overheating, and short-circuit protection. This ensures the longevity and reliability of the unit, even in demanding environments.

6. **User-Friendly Interface**: The intuitive user interface simplifies configuration and monitoring, allowing operators to quickly set up and manage the system. The built-in diagnostics provide real-time feedback, aiding in troubleshooting and maintenance tasks.

Usage Scenarios

The ABB ACS1000 BASE Object excels in diverse applications, making it a versatile choice for various industries. Here are some common usage scenarios:

1. **Pumping Systems**: In water and wastewater treatment plants, the ACS1000 can efficiently control pump speed, optimizing flow rates and reducing energy consumption.

2. **Conveyor Systems**: In manufacturing and logistics, the ACS1000 provides precise control of conveyor belts, ensuring smooth operation and minimizing downtime.

3. **Fan and Blower Control**: The ACS1000 is ideal for industrial ventilation systems, enabling variable speed control for fans and blowers, which enhances energy efficiency and reduces noise.

4. **Material Handling**: In material handling applications, such as cranes and hoists, the ACS1000 offers precise motion control, improving safety and operational efficiency.

5. **HVAC Systems**: The ACS1000 can be integrated into heating, ventilation, and air conditioning systems, allowing for enhanced energy management and comfort control.

Comparison with Other Models

When comparing the ABB ACS1000 BASE Object with other models in the ABB portfolio, several distinctions emerge. For instance:

– **ABB ACS880 Series**: While the ACS880 series provides advanced features like built-in safety functions and extensive connectivity options, the ACS1000 is tailored for applications requiring simpler control solutions, making it a cost-effective choice for less complex systems.

– **ABB ACS550**: The ACS550 is designed for standard applications with limited customization options. In contrast, the ACS1000 offers a more modular design, accommodating a broader range of applications and scalability.

– **ABB ACS310**: The ACS310 is geared towards compact applications with less demanding performance requirements. The ACS1000, however, is designed for high-performance scenarios, making it suitable for industrial-grade applications.

Related Models

For users seeking complementary solutions, here are ten related models within the ABB automation products portfolio that enhance or work seamlessly with the ACS1000 BASE Object:

1. **ABB UNS1860B-P**: A versatile control unit for process automation.

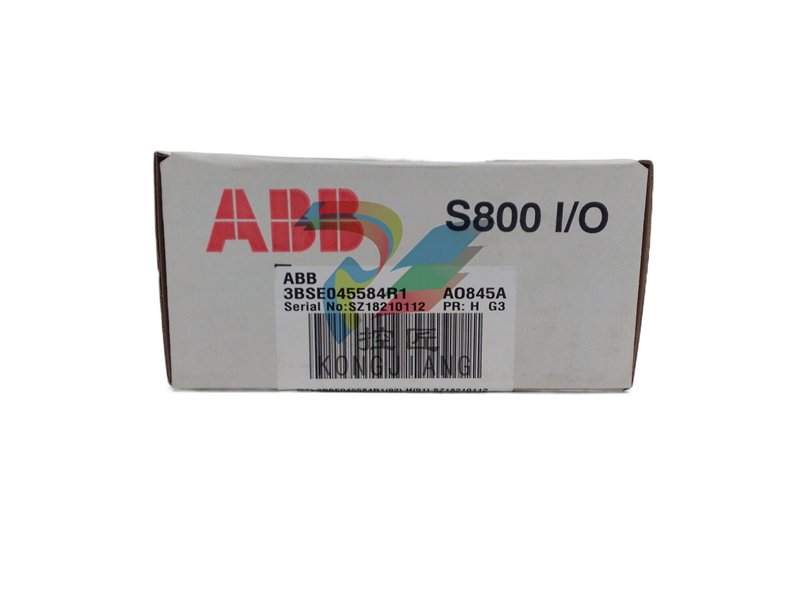

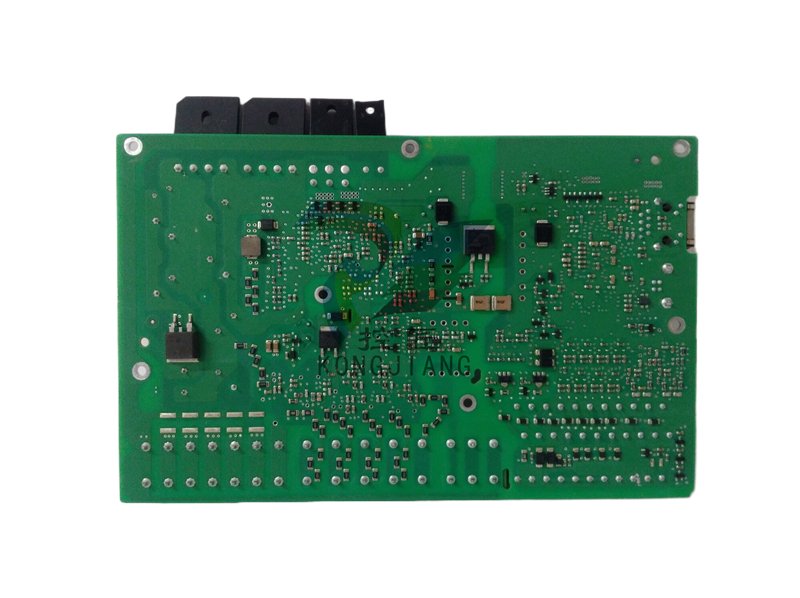

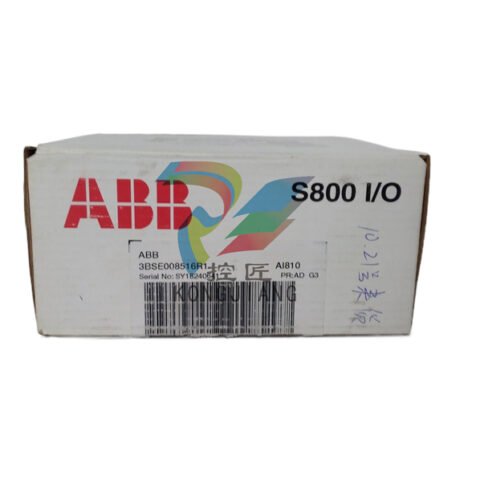

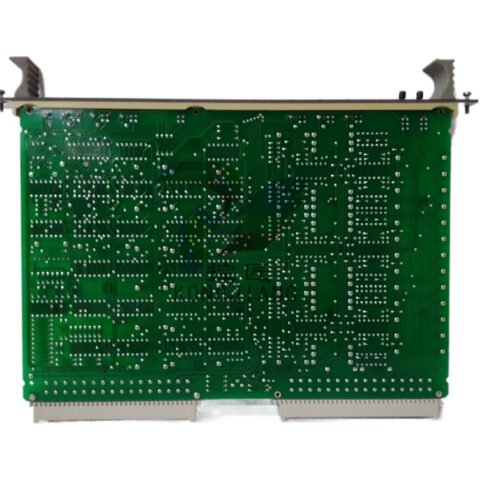

2. **ABB TU852 S800 I/O**: An input/output system that integrates with the ACS1000 for expanded functionality.

3. **ABB PM511V16**: A power management module that optimizes energy distribution.

4. **ABB 07DC91**: A control module offering enhanced processing capabilities.

5. **ABB ACS880-01-246A-3**: A high-performance drive for demanding applications.

6. **ABB DSQC352B**: A digital servo controller for precise motion control.

7. **ABB IRB 2600**: An industrial robot that can be controlled using the ACS1000 for automated tasks.

8. **ABB 3HNP04014-1**: A power supply unit that complements the ACS1000 in various installations.

9. **ABB SDCS-PIN-51**: A process interface that allows for better integration with the ACS1000.

10. **ABB ACS550**: A simplified version of a drive designed for less complex applications.

In summary, the ABB ACS1000 BASE Object stands out as a powerful and versatile solution for modern automation needs. Its advanced features, adaptability across various industries, and seamless integration with other ABB automation products make it an excellent choice for businesses looking to optimize their operations and enhance efficiency. Whether controlling pumps, conveyors, or HVAC systems, the ACS1000 BASE Object is engineered to deliver reliable performance and significant energy savings. Choose ABB for your automation needs and experience unparalleled innovation and efficiency.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The ABB ACS1000 BASE Object is engineered with advanced technology, ensuring optimal performance and reliability. Key features include:

1. **Modular Design**: The ACS1000 is built on a modular architecture, allowing for easy customization and scalability. Users can adapt the system to meet specific application requirements, making it suitable for a wide range of environments.

2. **High Efficiency**: With a power factor close to unity and minimal harmonic distortion, the ABB ACS1000 BASE Object ensures high energy efficiency, reducing operational costs and minimizing environmental impact.

3. **Flexible Control Options**: The system supports various control strategies, including vector control and direct torque control, providing superior performance in speed and torque management. This flexibility makes it ideal for applications ranging from simple pump control to complex motion control tasks.

4. **Advanced Communication Protocols**: The ACS1000 is equipped with multiple communication protocols, including Ethernet/IP and Modbus TCP, enabling seamless integration with existing systems and easy data exchange across the network. This feature enhances interoperability with other ABB automation products and third-party devices.

5. **Robust Protection Features**: Designed to withstand harsh conditions, the ACS1000 incorporates various protection mechanisms, including overcurrent, overheating, and short-circuit protection. This ensures the longevity and reliability of the unit, even in demanding environments.

6. **User-Friendly Interface**: The intuitive user interface simplifies configuration and monitoring, allowing operators to quickly set up and manage the system. The built-in diagnostics provide real-time feedback, aiding in troubleshooting and maintenance tasks.

Usage Scenarios

The ABB ACS1000 BASE Object excels in diverse applications, making it a versatile choice for various industries. Here are some common usage scenarios:

1. **Pumping Systems**: In water and wastewater treatment plants, the ACS1000 can efficiently control pump speed, optimizing flow rates and reducing energy consumption.

2. **Conveyor Systems**: In manufacturing and logistics, the ACS1000 provides precise control of conveyor belts, ensuring smooth operation and minimizing downtime.

3. **Fan and Blower Control**: The ACS1000 is ideal for industrial ventilation systems, enabling variable speed control for fans and blowers, which enhances energy efficiency and reduces noise.

4. **Material Handling**: In material handling applications, such as cranes and hoists, the ACS1000 offers precise motion control, improving safety and operational efficiency.

5. **HVAC Systems**: The ACS1000 can be integrated into heating, ventilation, and air conditioning systems, allowing for enhanced energy management and comfort control.

Comparison with Other Models

When comparing the ABB ACS1000 BASE Object with other models in the ABB portfolio, several distinctions emerge. For instance:

– **ABB ACS880 Series**: While the ACS880 series provides advanced features like built-in safety functions and extensive connectivity options, the ACS1000 is tailored for applications requiring simpler control solutions, making it a cost-effective choice for less complex systems.

– **ABB ACS550**: The ACS550 is designed for standard applications with limited customization options. In contrast, the ACS1000 offers a more modular design, accommodating a broader range of applications and scalability.

– **ABB ACS310**: The ACS310 is geared towards compact applications with less demanding performance requirements. The ACS1000, however, is designed for high-performance scenarios, making it suitable for industrial-grade applications.

Related Models

For users seeking complementary solutions, here are ten related models within the ABB automation products portfolio that enhance or work seamlessly with the ACS1000 BASE Object:

1. **ABB UNS1860B-P**: A versatile control unit for process automation.

2. **ABB TU852 S800 I/O**: An input/output system that integrates with the ACS1000 for expanded functionality.

3. **ABB PM511V16**: A power management module that optimizes energy distribution.

4. **ABB 07DC91**: A control module offering enhanced processing capabilities.

5. **ABB ACS880-01-246A-3**: A high-performance drive for demanding applications.

6. **ABB DSQC352B**: A digital servo controller for precise motion control.

7. **ABB IRB 2600**: An industrial robot that can be controlled using the ACS1000 for automated tasks.

8. **ABB 3HNP04014-1**: A power supply unit that complements the ACS1000 in various installations.

9. **ABB SDCS-PIN-51**: A process interface that allows for better integration with the ACS1000.

10. **ABB ACS550**: A simplified version of a drive designed for less complex applications.

In summary, the ABB ACS1000 BASE Object stands out as a powerful and versatile solution for modern automation needs. Its advanced features, adaptability across various industries, and seamless integration with other ABB automation products make it an excellent choice for businesses looking to optimize their operations and enhance efficiency. Whether controlling pumps, conveyors, or HVAC systems, the ACS1000 BASE Object is engineered to deliver reliable performance and significant energy savings. Choose ABB for your automation needs and experience unparalleled innovation and efficiency.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.