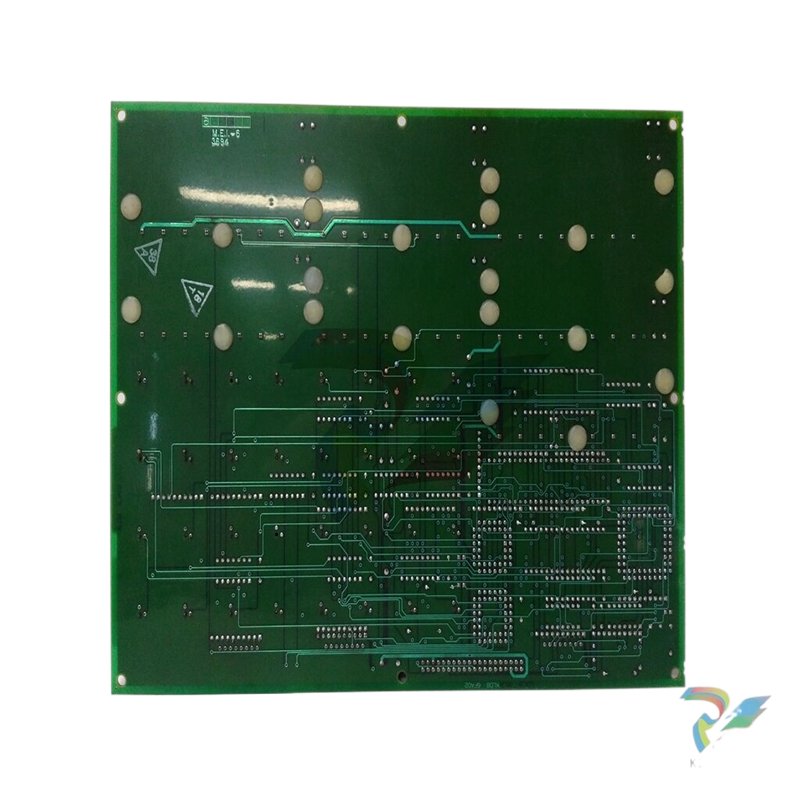

GE Industrial Automation IC698CHS009A Control System Module

Introducing the GE Industrial Model: A Pinnacle of Engineering Excellence

In the realm of industrial automation, the GE Industrial model stands out as a robust solution designed to meet the demanding requirements of modern manufacturing and process control environments. GE has long been a trusted name in automation technology, and this model is no exception, delivering unparalleled performance, reliability, and versatility.

Key Technical Features

The GE Industrial model is engineered with cutting-edge technology that ensures seamless integration into existing systems while providing advanced capabilities. Some of its key technical features include:

1. **High Processing Speed**: Equipped with a powerful microprocessor, the GE Industrial model can handle complex calculations and control tasks with remarkable speed, significantly enhancing overall operational efficiency.

2. **Scalability**: Designed to grow with your business, this model allows for easy scalability. Users can expand their systems by integrating additional modules and components without the need for extensive reconfiguration.

3. **Robust Communication Protocols**: The GE Industrial model supports a variety of communication protocols, including Ethernet/IP, Modbus, and Profibus, enabling it to interface seamlessly with a wide range of devices and systems.

4. **Flexible I/O Options**: With a comprehensive selection of input and output modules, the GE Industrial model caters to diverse applications, from simple control tasks to complex automation processes.

5. **User-Friendly Interface**: The intuitive user interface simplifies the programming and monitoring processes, allowing operators to easily navigate the system and make adjustments as needed.

6. **High Reliability**: Built to endure the rigors of industrial environments, the GE Industrial model features rugged construction and high-quality components that ensure long-term reliability and minimal downtime.

Usage Scenarios

The versatility of the GE Industrial model makes it suitable for a wide array of applications across various industries. Here are some common usage scenarios:

1. **Manufacturing Automation**: In manufacturing plants, the GE Industrial model can be employed to control machinery, manage production lines, and optimize workflow, leading to increased productivity and lower operational costs.

2. **Process Control**: This model is ideal for process industries, such as oil and gas, chemical, and pharmaceuticals, where precise control of variables like temperature, pressure, and flow is critical.

3. **Building Management Systems**: The GE Industrial model can be integrated into building management systems to monitor and control HVAC, lighting, and security systems, ensuring energy efficiency and occupant comfort.

4. **Energy Management**: Utility companies can leverage the capabilities of the GE Industrial model for monitoring and controlling energy distribution, helping to optimize grid performance and reduce waste.

5. **Transportation Systems**: In transportation applications, this model can be utilized to manage traffic signals, railway systems, and airport operations, enhancing safety and efficiency.

Comparison with Other Models

When compared to other models in the GE lineup, such as the GE IS200TBCIH1BBC and GE IS220PPROS1B, the GE Industrial model offers a more comprehensive feature set, particularly in terms of scalability and communication options. While the IS200TBCIH1BBC is renowned for its high-speed processing capabilities, the GE Industrial model expands upon this with enhanced I/O flexibility and a user-friendly interface.

In contrast, the GE CT7P70500470CW24 focuses primarily on specific industrial applications, whereas the GE Industrial model provides a versatile platform suitable for a wide range of industries. This makes it an excellent choice for businesses looking for a single solution to address various automation needs.

Notably, while the GE IS215UCVEH2AB is optimized for control systems, the GE Industrial model's robust communication protocols ensure compatibility with a broader spectrum of devices, making it a more future-proof investment.

Related Models

For those interested in exploring additional options within the GE family of automation products, consider the following related models:

1. **GE IS200PAICH2A**: Ideal for process control applications, offering similar robust features.

2. **GE IC697MDL250**: Known for its reliability in industrial settings, perfect for expanding existing systems.

3. **GE PRG-MODEM**: A communication device that enhances remote access capabilities.

4. **GE IS215UCVEH2AB**: A controller optimized for specific automation tasks.

5. **GE IC660ELB912G**: An excellent choice for applications requiring high-speed data processing.

6. **GE DS200CTBAG1ADD**: A versatile controller suitable for various industrial applications.

7. **GE 531X307LTBAJG1**: Tailored for specific control tasks, providing reliable performance.

8. **GE IS200TPROH1BBB**: Known for its advanced control features in manufacturing.

9. **GE IC670MDL740J**: A robust model ideal for complex industrial automation.

10. **GE IS220PRTDH1A**: A precision control solution for temperature monitoring and regulation.

In conclusion, the GE Industrial model exemplifies the intersection of cutting-edge technology and practical application in the field of automation. With its high processing speed, scalability, and robust communication protocols, it stands as a premier choice for businesses seeking to enhance their operational efficiency. Whether in manufacturing, process control, building management, or energy management, the GE Industrial model offers a reliable and versatile solution that will meet the evolving needs of industries today and into the future. Explore the potential of GE automation products and transform your operations with a trusted name in industrial excellence.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the realm of industrial automation, the GE Industrial model stands out as a robust solution designed to meet the demanding requirements of modern manufacturing and process control environments. GE has long been a trusted name in automation technology, and this model is no exception, delivering unparalleled performance, reliability, and versatility.

Key Technical Features

The GE Industrial model is engineered with cutting-edge technology that ensures seamless integration into existing systems while providing advanced capabilities. Some of its key technical features include:

1. **High Processing Speed**: Equipped with a powerful microprocessor, the GE Industrial model can handle complex calculations and control tasks with remarkable speed, significantly enhancing overall operational efficiency.

2. **Scalability**: Designed to grow with your business, this model allows for easy scalability. Users can expand their systems by integrating additional modules and components without the need for extensive reconfiguration.

3. **Robust Communication Protocols**: The GE Industrial model supports a variety of communication protocols, including Ethernet/IP, Modbus, and Profibus, enabling it to interface seamlessly with a wide range of devices and systems.

4. **Flexible I/O Options**: With a comprehensive selection of input and output modules, the GE Industrial model caters to diverse applications, from simple control tasks to complex automation processes.

5. **User-Friendly Interface**: The intuitive user interface simplifies the programming and monitoring processes, allowing operators to easily navigate the system and make adjustments as needed.

6. **High Reliability**: Built to endure the rigors of industrial environments, the GE Industrial model features rugged construction and high-quality components that ensure long-term reliability and minimal downtime.

Usage Scenarios

The versatility of the GE Industrial model makes it suitable for a wide array of applications across various industries. Here are some common usage scenarios:

1. **Manufacturing Automation**: In manufacturing plants, the GE Industrial model can be employed to control machinery, manage production lines, and optimize workflow, leading to increased productivity and lower operational costs.

2. **Process Control**: This model is ideal for process industries, such as oil and gas, chemical, and pharmaceuticals, where precise control of variables like temperature, pressure, and flow is critical.

3. **Building Management Systems**: The GE Industrial model can be integrated into building management systems to monitor and control HVAC, lighting, and security systems, ensuring energy efficiency and occupant comfort.

4. **Energy Management**: Utility companies can leverage the capabilities of the GE Industrial model for monitoring and controlling energy distribution, helping to optimize grid performance and reduce waste.

5. **Transportation Systems**: In transportation applications, this model can be utilized to manage traffic signals, railway systems, and airport operations, enhancing safety and efficiency.

Comparison with Other Models

When compared to other models in the GE lineup, such as the GE IS200TBCIH1BBC and GE IS220PPROS1B, the GE Industrial model offers a more comprehensive feature set, particularly in terms of scalability and communication options. While the IS200TBCIH1BBC is renowned for its high-speed processing capabilities, the GE Industrial model expands upon this with enhanced I/O flexibility and a user-friendly interface.

In contrast, the GE CT7P70500470CW24 focuses primarily on specific industrial applications, whereas the GE Industrial model provides a versatile platform suitable for a wide range of industries. This makes it an excellent choice for businesses looking for a single solution to address various automation needs.

Notably, while the GE IS215UCVEH2AB is optimized for control systems, the GE Industrial model's robust communication protocols ensure compatibility with a broader spectrum of devices, making it a more future-proof investment.

Related Models

For those interested in exploring additional options within the GE family of automation products, consider the following related models:

1. **GE IS200PAICH2A**: Ideal for process control applications, offering similar robust features.

2. **GE IC697MDL250**: Known for its reliability in industrial settings, perfect for expanding existing systems.

3. **GE PRG-MODEM**: A communication device that enhances remote access capabilities.

4. **GE IS215UCVEH2AB**: A controller optimized for specific automation tasks.

5. **GE IC660ELB912G**: An excellent choice for applications requiring high-speed data processing.

6. **GE DS200CTBAG1ADD**: A versatile controller suitable for various industrial applications.

7. **GE 531X307LTBAJG1**: Tailored for specific control tasks, providing reliable performance.

8. **GE IS200TPROH1BBB**: Known for its advanced control features in manufacturing.

9. **GE IC670MDL740J**: A robust model ideal for complex industrial automation.

10. **GE IS220PRTDH1A**: A precision control solution for temperature monitoring and regulation.

In conclusion, the GE Industrial model exemplifies the intersection of cutting-edge technology and practical application in the field of automation. With its high processing speed, scalability, and robust communication protocols, it stands as a premier choice for businesses seeking to enhance their operational efficiency. Whether in manufacturing, process control, building management, or energy management, the GE Industrial model offers a reliable and versatile solution that will meet the evolving needs of industries today and into the future. Explore the potential of GE automation products and transform your operations with a trusted name in industrial excellence.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.