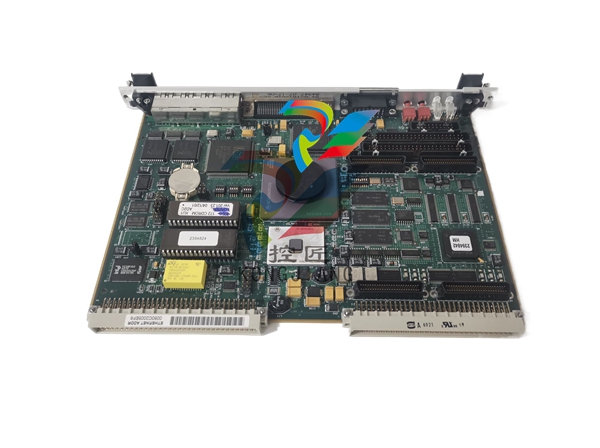

GE 8044-CC-20 Carrier extension cable, 2.0m

GE 8044-CC-20 Carrier extension cable, 2.0m

On-line download

Users with safety responsibility can

download new parameters to a SafetyNet

Controller, from a Trusted Host, to a

Controller whose Key Switch is set to permit

new downloads and where the particular

SafetyNet Controller’s Password is known.

New parameter download is carried out as a

background task over a number of cycles to

ensure that the fault reaction and response

times are not compromised. Once download

is complete and the new parameters have

passed the checking and security tests, the

new parameters will be automatically

adopted. Where redundant SafetyNet

Controllers are used, the stand-by Controller

will also be automatically updated.

Note: on-line download should only be used

where there are adequate procedures for

approving the changes that have been made

and testing them prior to download.

Static Analysis Tool

Any safety-related application program must

be developed by suitably qualified personnel

and must be subject to careful scrutiny to

ensure safety, but the Workbench provides

an additional safety test. The Static Analysis

Tool checks for illegal constructs within the

safety program prior to download.

Differences Utility

Once a new SafetyNet application is

successfully compiled, it can be downloaded

to a SafetyNet Controller. On download, two

text reports are generated: a Download

Report and a Master Tag Xref. These can be

used for comparison with other downloads

using the Differences Utility.

Download backup

A time stamped backup of each safety

application is automatically created

following a successful download. Changes

between versions can be viewed and

backups can be used either as a start point

for developing new safety applications or to

restore an earlier version.

Change Control Log

The Workbench maintains a Change Control

Log that records – for example – when:

♦ IO Modules are added, deleted or moved

♦ Tags are added to, removed from, or

moved within an IO Module

♦ IO Configuration parameters are saved

♦ Controller IP addresses or node

numbers are entered or modified

♦ External node numbers are entered or

modified

♦ Serial communications parameters are

entered or modified

♦ A successful download is made

♦ A Strategy is removed

♦ The Controller password is changed

General

SafetyNet IO Modules interface to safety

system field wiring via Field Terminals.

The IO Modules and the Field Terminals

mount on Carriers that provide

mechanical support, but also connect the

internal communication bus and power

supply connections to the Modules.

The IO Modules are certified as suitable

for use in SIL 2 safety-related

applications.

Certification

The SafetyNet IO Modules are certified for

use in safety-related applications up to and

including SIL 2. The SafetyNet System

achieves this certification with a 1oo1D

architecture.

The SafetyNet IO Modules have been

designed specifically for safety-related

applications and are certified on the basis of

the excellence of their design. The

certification does not depend on “proven in

use” data.

Diagnostics

The IO Modules perform comprehensive

internal diagnostic tests as an essential part

of ensuring that the IO can carry out the

required safety function.

If the SafetyNet IO Module’s internal

diagnostics detect a fault that would prevent

the SafetyNet System from carrying out its

safety function, then it will initiate a controlled

shutdown. A controlled shutdown has two

objectives – firstly, to ensure that the IO

Module enters its failsafe mode; and

secondly, to record sufficient data to allow the

reason for the shutdown to be determined.

If a SafetyNet Module enters a controlled

shutdown, then all IO channels are de activated: input channels are not scanned;

and output channels are de-energised.

Bussed Field Power

The Bussed Field Power (BFP) connectors on

the rear of IO Module Carriers provide the

power connections for field instruments

wired to the IO Modules.

For the SafetyNet System, BFP must be 24V

dc and supplied by MTL’s 8914-PS-AC units.

These power supplies may be used in

redundant pairs, if required.

Live maintenance

SafetyNet IO Modules can be removed and

replaced in a Class 1, Division 2 or Zone 2

hazardous area – once the relevant Bussed

Field Power (BFP) connection has been

isolated using an appropriate hazardous

area switch (such as the MTL951). Removing

and replacing the Modules does not

interrupt the operation of the other parts of

the node.

If a Module is replaced by another Module

of identically the same type, then no

intervention is required for the System to

begin operating normally once the Bussed

Field Power is restored.