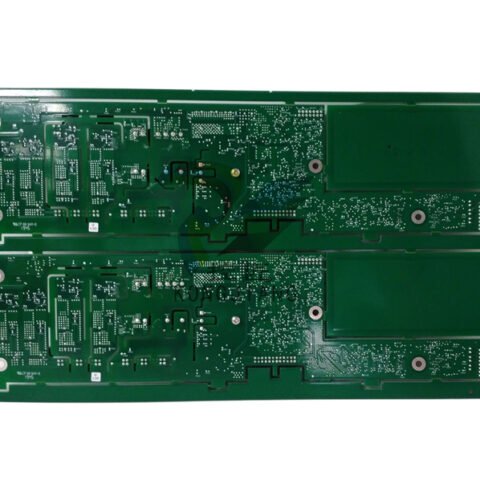

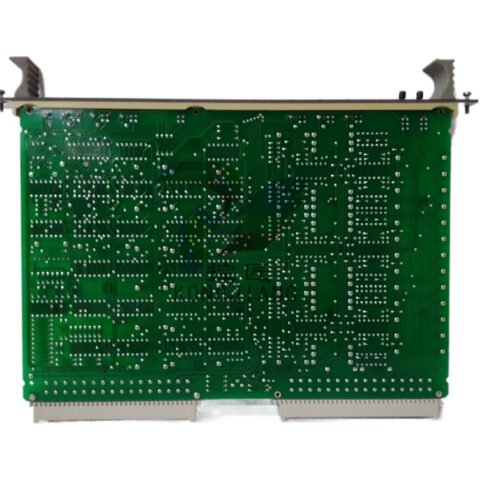

ABB 3BHE022293R0101 PCD232 Communications I/O Module – Enhancing Industrial Communication Efficiency

Introducing the ABB 3BHE022293R0101 PCD232, a pivotal addition to ABB's extensive range of automation products designed to enhance operational efficiency and reliability in various industrial applications. As a trusted name in the automation sector, ABB continues to innovate with advanced technology solutions, and the PCD232 model exemplifies this commitment.

Key Technical Features:

The ABB 3BHE022293R0101 PCD232 is engineered with cutting-edge technology, boasting several key features that set it apart from its competitors. One of its standout attributes is its robust processing capability, allowing for real-time data processing and control. This model integrates seamlessly with ABB’s extensive portfolio of automation products, ensuring compatibility and ease of integration into existing systems.

Equipped with multiple communication interfaces, including Ethernet and serial communication, the PCD232 facilitates efficient data exchange and connectivity with various devices and systems. Its modular design promotes flexibility, enabling users to customize configurations according to specific operational requirements. With a high tolerance for environmental conditions, the ABB 3BHE022293R0101 PCD232 is built to withstand the rigors of industrial environments, ensuring longevity and dependable performance.

Moreover, the PCD232 features advanced diagnostic and monitoring capabilities that provide users with real-time insights, allowing for proactive maintenance and reduced downtime. The intuitive user interface enhances usability, making it accessible for both seasoned professionals and newcomers to the automation field.

Usage Scenarios:

The ABB 3BHE022293R0101 PCD232 is versatile and can be deployed across various industries, including manufacturing, energy, and process control. In manufacturing environments, it can be utilized for machine control, monitoring production lines, and optimizing workflow processes. Its ability to integrate with sensors and actuators allows for precise control over machinery, thereby enhancing productivity and reducing operational costs.

In the energy sector, the PCD232 can be employed for monitoring and controlling power distribution systems, ensuring efficient energy management and minimizing losses. Additionally, in process industries, it can facilitate real-time monitoring and control of chemical processes, contributing to safety and compliance with regulatory standards.

Comparison with Other Models:

When compared to other models in the ABB lineup, such as the ABB PCD231 (3BHE025541R0101), the PCD232 offers enhanced processing capabilities, making it more suitable for complex and data-intensive applications. While the PCD231 serves well in standard automation tasks, the PCD232’s advanced diagnostic features provide greater insights into system performance.

Similarly, when benchmarked against ABB's TU841 (3BSE020848R1) and TU852 S800 I/O, the PCD232 stands out with its superior modularity and communication options. The TU841 and TU852 are excellent for I/O tasks but may lack the extensive processing power and advanced monitoring capabilities that the PCD232 provides.

Furthermore, the ABB 3BHE022293R0101 PCD232 competes favorably with models like ABB 3HAC16035-1 and ABB DC551-CS31, which are known for their reliability in control applications. However, the PCD232’s enhanced connectivity options and real-time processing make it a more modern choice for industrial automation needs.

Reference to Related Models:

For those seeking complementary or alternative automation solutions, ABB offers a variety of related models that can enhance your operational capabilities. Consider the following:

1. ABB UNS1860B-P, V1 (3BHB001336R0001) – A reliable model for basic control applications.

2. ABB PPE100A (3BHE037824R0101) – Ideal for power distribution and energy management.

3. ABB YPM106E (YT204001-FN) – A versatile solution for various industrial applications.

4. ABB PM511V16 (3BSE011181R1) – Known for its high performance in process automation.

5. ABB AO810 (3BSE038415R1) – A great choice for analog output solutions.

6. ABB SDCS-PIN-51 (3BSE004940R1) – Designed for power and control systems in the energy sector.

7. ABB 07DC91 – A dependable model for discrete control applications.

8. ABB ACS880-01-246A-3 (3ABD00035954-D) – A high-performance drive solution for motor control.

9. ABB DSQC352B – Ideal for robotic control and automation.

10. ABB IRB 2600 – A versatile industrial robot designed for high-speed applications.

In conclusion, the ABB 3BHE022293R0101 PCD232 is a powerful automation product that combines advanced technology with user-friendly features. Its versatility makes it suitable for a wide range of industrial applications, while its robust design ensures reliability and longevity in challenging environments. Whether you're upgrading your existing systems or implementing new automation solutions, the PCD232 stands ready to meet your needs, driving efficiency and productivity in your operations. Choose ABB automation products for innovative solutions that deliver results.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The ABB 3BHE022293R0101 PCD232 is engineered with cutting-edge technology, boasting several key features that set it apart from its competitors. One of its standout attributes is its robust processing capability, allowing for real-time data processing and control. This model integrates seamlessly with ABB’s extensive portfolio of automation products, ensuring compatibility and ease of integration into existing systems.

Equipped with multiple communication interfaces, including Ethernet and serial communication, the PCD232 facilitates efficient data exchange and connectivity with various devices and systems. Its modular design promotes flexibility, enabling users to customize configurations according to specific operational requirements. With a high tolerance for environmental conditions, the ABB 3BHE022293R0101 PCD232 is built to withstand the rigors of industrial environments, ensuring longevity and dependable performance.

Moreover, the PCD232 features advanced diagnostic and monitoring capabilities that provide users with real-time insights, allowing for proactive maintenance and reduced downtime. The intuitive user interface enhances usability, making it accessible for both seasoned professionals and newcomers to the automation field.

Usage Scenarios:

The ABB 3BHE022293R0101 PCD232 is versatile and can be deployed across various industries, including manufacturing, energy, and process control. In manufacturing environments, it can be utilized for machine control, monitoring production lines, and optimizing workflow processes. Its ability to integrate with sensors and actuators allows for precise control over machinery, thereby enhancing productivity and reducing operational costs.

In the energy sector, the PCD232 can be employed for monitoring and controlling power distribution systems, ensuring efficient energy management and minimizing losses. Additionally, in process industries, it can facilitate real-time monitoring and control of chemical processes, contributing to safety and compliance with regulatory standards.

Comparison with Other Models:

When compared to other models in the ABB lineup, such as the ABB PCD231 (3BHE025541R0101), the PCD232 offers enhanced processing capabilities, making it more suitable for complex and data-intensive applications. While the PCD231 serves well in standard automation tasks, the PCD232’s advanced diagnostic features provide greater insights into system performance.

Similarly, when benchmarked against ABB's TU841 (3BSE020848R1) and TU852 S800 I/O, the PCD232 stands out with its superior modularity and communication options. The TU841 and TU852 are excellent for I/O tasks but may lack the extensive processing power and advanced monitoring capabilities that the PCD232 provides.

Furthermore, the ABB 3BHE022293R0101 PCD232 competes favorably with models like ABB 3HAC16035-1 and ABB DC551-CS31, which are known for their reliability in control applications. However, the PCD232’s enhanced connectivity options and real-time processing make it a more modern choice for industrial automation needs.

Reference to Related Models:

For those seeking complementary or alternative automation solutions, ABB offers a variety of related models that can enhance your operational capabilities. Consider the following:

1. ABB UNS1860B-P, V1 (3BHB001336R0001) – A reliable model for basic control applications.

2. ABB PPE100A (3BHE037824R0101) – Ideal for power distribution and energy management.

3. ABB YPM106E (YT204001-FN) – A versatile solution for various industrial applications.

4. ABB PM511V16 (3BSE011181R1) – Known for its high performance in process automation.

5. ABB AO810 (3BSE038415R1) – A great choice for analog output solutions.

6. ABB SDCS-PIN-51 (3BSE004940R1) – Designed for power and control systems in the energy sector.

7. ABB 07DC91 – A dependable model for discrete control applications.

8. ABB ACS880-01-246A-3 (3ABD00035954-D) – A high-performance drive solution for motor control.

9. ABB DSQC352B – Ideal for robotic control and automation.

10. ABB IRB 2600 – A versatile industrial robot designed for high-speed applications.

In conclusion, the ABB 3BHE022293R0101 PCD232 is a powerful automation product that combines advanced technology with user-friendly features. Its versatility makes it suitable for a wide range of industrial applications, while its robust design ensures reliability and longevity in challenging environments. Whether you're upgrading your existing systems or implementing new automation solutions, the PCD232 stands ready to meet your needs, driving efficiency and productivity in your operations. Choose ABB automation products for innovative solutions that deliver results.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.