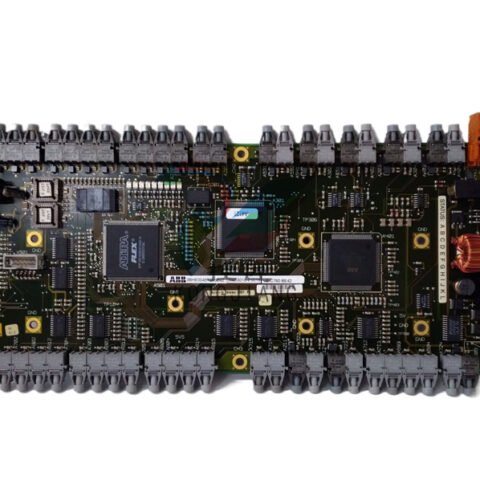

ABB BCU-12 Control Unit for Industrial Automation Systems

Introducing the ABB BCU-12: A Cutting-Edge Solution for Advanced Control Systems

In the fast-evolving world of industrial automation, the ABB BCU-12 stands out as a premier solution designed to elevate control and monitoring capabilities across a wide array of applications. As part of ABB's renowned automation products, the BCU-12 integrates advanced technology with user-friendly features, ensuring both efficiency and reliability in your operations.

Key Technical Features

The ABB BCU-12 boasts an array of technical features that make it a versatile choice for many industrial applications. At its core, the BCU-12 is equipped with high-performance processing capabilities, allowing for rapid data processing and seamless communication with other devices in your automation network.

Key specifications include:

1. **Robust Communication Interfaces**: The BCU-12 supports multiple communication protocols, including Ethernet/IP, Modbus TCP, and Profibus, enabling it to integrate effortlessly with various systems and devices. This ensures flexibility in system design and easy scalability as your needs grow.

2. **Enhanced I/O Capabilities**: With a modular design, the BCU-12 allows for extensive input/output options, accommodating both digital and analog signals. This feature is critical for applications that require diverse data inputs.

3. **Advanced Diagnostics and Monitoring**: The BCU-12 comes with built-in diagnostic tools that provide real-time insights into system performance. This proactive monitoring capability helps in identifying potential issues before they escalate, thereby reducing downtime and maintenance costs.

4. **User-Friendly Interface**: The intuitive graphical user interface (GUI) simplifies the configuration and management of the control system, reducing the learning curve for new users and enhancing operational efficiency.

5. **High Reliability and Safety Standards**: Built with industrial-grade components, the BCU-12 meets stringent safety and reliability standards. It is designed to operate in demanding environments, ensuring consistent performance even in the most challenging conditions.

Usage Scenarios

The ABB BCU-12 is ideal for a wide range of industrial applications across various sectors, including manufacturing, energy, and infrastructure.

1. **Manufacturing Automation**: In manufacturing settings, the BCU-12 can be used to control and monitor production lines, ensuring optimal performance and minimal waste through precise control of machinery and processes.

2. **Energy Management**: The BCU-12 is well-suited for energy management systems where it can monitor energy consumption, optimize resource allocation, and enhance overall efficiency in power distribution.

3. **Building Automation**: For building management systems, the BCU-12 can integrate HVAC, lighting, and security systems, providing centralized control that enhances comfort and safety while reducing energy costs.

4. **Infrastructure Projects**: In large infrastructure projects, such as water treatment facilities or transportation systems, the BCU-12 can coordinate various automation tasks, ensuring smooth operation and compliance with regulatory standards.

Comparison with Other Models

When comparing the ABB BCU-12 with other models in the ABB automation portfolio, such as the ABB DI810, ABB PM861K01, and ABB CI868K01-eA, several distinct advantages become apparent.

1. **Scalability**: While models like the ABB DI810 may offer specific I/O capabilities, the modular design of the BCU-12 allows for future expansion without the need for a complete system overhaul.

2. **Versatility**: The BCU-12's compatibility with multiple communication protocols provides an edge over models such as the ABB 216NG63A, which may have limited connectivity options.

3. **User Interface**: The BCU-12’s user-friendly GUI is a significant improvement compared to the more complex interfaces found in older models, such as the ABB 57160001-KX, making it easier for operators to navigate and configure settings.

4. **Diagnostics**: The advanced diagnostics and monitoring features of the BCU-12 provide deeper insights compared to basic functionalities found in models like ABB RB520, enhancing system reliability.

Related Models

The ABB BCU-12 is part of a comprehensive range of automation products offered by ABB. Here are ten related models that complement its functionality:

1. **ABB DI810**: Digital input module designed for various control applications.

2. **ABB PM861K01**: Process manager for advanced control and monitoring.

3. **ABB CI868K01-eA**: Communication interface for seamless integration with field devices.

4. **ABB 216NG63A**: I/O module with a focus on flexibility in industrial applications.

5. **ABB 12KM02E-V0002**: Versatile I/O solution suitable for various automation tasks.

6. **ABB 3HAC17484-8108**: High-performance communication and control unit.

7. **ABB 5SHY6545L0001 AC10272001R0101**: AC drive designed for efficient motor control.

8. **ABB SLMG99**: Smart local management gateway for integrated building automation.

9. **ABB 07KT97B**: Controller designed for specific process automation tasks.

10. **ABB DSPC170**: Digital signal processing controller for real-time applications.

Conclusion

The ABB BCU-12 represents a significant advancement in industrial automation technology. With its robust technical features, versatility across various applications, and compatibility with other ABB automation products, it is an essential component for any modern industrial setup. Its user-friendly interface and advanced diagnostic capabilities further enhance its appeal, making it an excellent choice for businesses looking to optimize their operations. Upgrade your automation solutions with the ABB BCU-12 and experience the future of industrial control systems.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the fast-evolving world of industrial automation, the ABB BCU-12 stands out as a premier solution designed to elevate control and monitoring capabilities across a wide array of applications. As part of ABB's renowned automation products, the BCU-12 integrates advanced technology with user-friendly features, ensuring both efficiency and reliability in your operations.

Key Technical Features

The ABB BCU-12 boasts an array of technical features that make it a versatile choice for many industrial applications. At its core, the BCU-12 is equipped with high-performance processing capabilities, allowing for rapid data processing and seamless communication with other devices in your automation network.

Key specifications include:

1. **Robust Communication Interfaces**: The BCU-12 supports multiple communication protocols, including Ethernet/IP, Modbus TCP, and Profibus, enabling it to integrate effortlessly with various systems and devices. This ensures flexibility in system design and easy scalability as your needs grow.

2. **Enhanced I/O Capabilities**: With a modular design, the BCU-12 allows for extensive input/output options, accommodating both digital and analog signals. This feature is critical for applications that require diverse data inputs.

3. **Advanced Diagnostics and Monitoring**: The BCU-12 comes with built-in diagnostic tools that provide real-time insights into system performance. This proactive monitoring capability helps in identifying potential issues before they escalate, thereby reducing downtime and maintenance costs.

4. **User-Friendly Interface**: The intuitive graphical user interface (GUI) simplifies the configuration and management of the control system, reducing the learning curve for new users and enhancing operational efficiency.

5. **High Reliability and Safety Standards**: Built with industrial-grade components, the BCU-12 meets stringent safety and reliability standards. It is designed to operate in demanding environments, ensuring consistent performance even in the most challenging conditions.

Usage Scenarios

The ABB BCU-12 is ideal for a wide range of industrial applications across various sectors, including manufacturing, energy, and infrastructure.

1. **Manufacturing Automation**: In manufacturing settings, the BCU-12 can be used to control and monitor production lines, ensuring optimal performance and minimal waste through precise control of machinery and processes.

2. **Energy Management**: The BCU-12 is well-suited for energy management systems where it can monitor energy consumption, optimize resource allocation, and enhance overall efficiency in power distribution.

3. **Building Automation**: For building management systems, the BCU-12 can integrate HVAC, lighting, and security systems, providing centralized control that enhances comfort and safety while reducing energy costs.

4. **Infrastructure Projects**: In large infrastructure projects, such as water treatment facilities or transportation systems, the BCU-12 can coordinate various automation tasks, ensuring smooth operation and compliance with regulatory standards.

Comparison with Other Models

When comparing the ABB BCU-12 with other models in the ABB automation portfolio, such as the ABB DI810, ABB PM861K01, and ABB CI868K01-eA, several distinct advantages become apparent.

1. **Scalability**: While models like the ABB DI810 may offer specific I/O capabilities, the modular design of the BCU-12 allows for future expansion without the need for a complete system overhaul.

2. **Versatility**: The BCU-12's compatibility with multiple communication protocols provides an edge over models such as the ABB 216NG63A, which may have limited connectivity options.

3. **User Interface**: The BCU-12’s user-friendly GUI is a significant improvement compared to the more complex interfaces found in older models, such as the ABB 57160001-KX, making it easier for operators to navigate and configure settings.

4. **Diagnostics**: The advanced diagnostics and monitoring features of the BCU-12 provide deeper insights compared to basic functionalities found in models like ABB RB520, enhancing system reliability.

Related Models

The ABB BCU-12 is part of a comprehensive range of automation products offered by ABB. Here are ten related models that complement its functionality:

1. **ABB DI810**: Digital input module designed for various control applications.

2. **ABB PM861K01**: Process manager for advanced control and monitoring.

3. **ABB CI868K01-eA**: Communication interface for seamless integration with field devices.

4. **ABB 216NG63A**: I/O module with a focus on flexibility in industrial applications.

5. **ABB 12KM02E-V0002**: Versatile I/O solution suitable for various automation tasks.

6. **ABB 3HAC17484-8108**: High-performance communication and control unit.

7. **ABB 5SHY6545L0001 AC10272001R0101**: AC drive designed for efficient motor control.

8. **ABB SLMG99**: Smart local management gateway for integrated building automation.

9. **ABB 07KT97B**: Controller designed for specific process automation tasks.

10. **ABB DSPC170**: Digital signal processing controller for real-time applications.

Conclusion

The ABB BCU-12 represents a significant advancement in industrial automation technology. With its robust technical features, versatility across various applications, and compatibility with other ABB automation products, it is an essential component for any modern industrial setup. Its user-friendly interface and advanced diagnostic capabilities further enhance its appeal, making it an excellent choice for businesses looking to optimize their operations. Upgrade your automation solutions with the ABB BCU-12 and experience the future of industrial control systems.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.