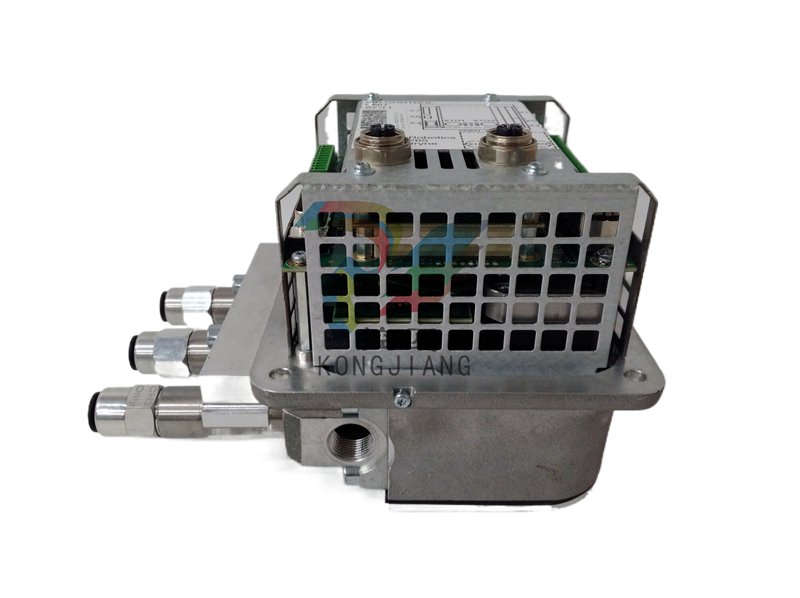

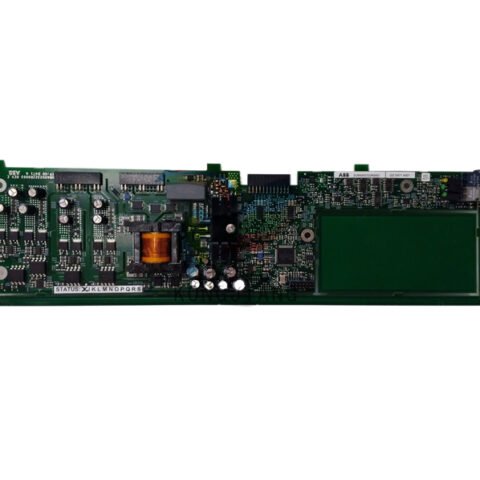

ABB EI813F Ethernet Module, High-Speed Industrial Communication Interface

Introducing the ABB EI813F, a pinnacle of innovation in the realm of ABB automation products. This advanced modular I/O device is designed to streamline operations, enhance productivity, and integrate seamlessly into a wide range of industrial applications. With its robust engineering, the ABB EI813F stands out in the ABB portfolio, offering superior performance and reliability.

**Key Technical Features**

The ABB EI813F is engineered with a suite of technical features that cater to the needs of modern industrial environments. Key specifications include:

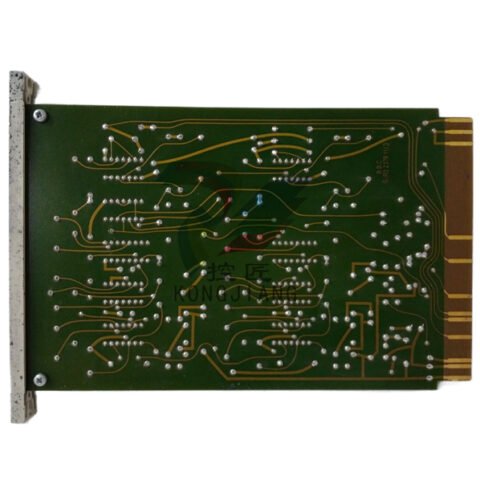

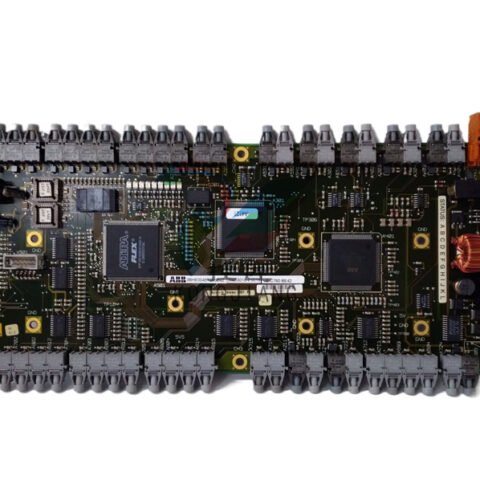

– **Modular Design**: The EI813F features a modular design, allowing for easy integration into existing systems while enabling future scalability. This modularity ensures that users can customize their configurations to fit specific operational requirements.

– **High-Speed Communication**: Equipped with advanced communication protocols, the ABB EI813F supports high-speed data transfer, ensuring real-time monitoring and control. This feature is critical for maintaining operational efficiency and reducing latency in data processing.

– **Versatile I/O Options**: The device supports a variety of input and output configurations. Whether dealing with digital or analog signals, the EI813F provides the flexibility needed for diverse applications, from process control to machine automation.

– **Robust Environmental Ratings**: Designed to withstand harsh industrial conditions, the EI813F has an IP rating that ensures protection against dust and moisture, making it suitable for various environments, including manufacturing plants, oil and gas facilities, and utility sectors.

– **User-Friendly Interface**: The intuitive interface simplifies setup and operation, allowing users to easily configure parameters and monitor system status. This usability is a significant advantage in minimizing training time and operational errors.

– **Integrated Diagnostics**: The ABB EI813F comes equipped with built-in diagnostic features that facilitate proactive maintenance, helping to reduce downtime and extend the lifespan of equipment.

**Usage Scenarios**

The ABB EI813F is versatile and can be applied across multiple industry sectors. Here are some practical usage scenarios:

1. **Manufacturing Automation**: The EI813F can be utilized in assembly lines for real-time monitoring of machinery performance, ensuring operational efficiency and minimizing production delays.

2. **Energy Management**: In power generation and distribution, the device can monitor energy consumption and analyze performance data to optimize grid operations.

3. **Process Control**: The EI813F is ideal for controlling various industrial processes, such as chemical production, where precise monitoring and control of variables like temperature and pressure are crucial.

4. **Building Management Systems**: In smart buildings, the device can be integrated into HVAC systems to optimize energy usage and enhance comfort levels for occupants.

5. **Transportation Systems**: The EI813F can be employed in automated traffic management systems to monitor vehicle flow and optimize signaling based on real-time data.

**Comparison with Other Models**

When comparing the ABB EI813F to other models in the ABB portfolio, such as the ABB DI810 and ABB CI868K01-eA, several distinctions emerge. The DI810 focuses primarily on digital inputs and outputs, making it suitable for applications requiring straightforward on/off control. In contrast, the EI813F offers a broader range of I/O options, including advanced analog capabilities, making it more versatile for complex applications.

Another model, the ABB PM861K01, is tailored for power management systems, providing comprehensive energy monitoring features. While the PM861K01 excels in energy management, the EI813F's modular design and high-speed communication make it a preferred choice for applications requiring extensive data integration and processing capabilities.

Additionally, the ABB CI855-1 is renowned for its high-speed processing, but it does not feature the same level of environmental protection as the EI813F. This makes the EI813F more suitable for demanding industrial environments where durability is key.

**Related Models**

For those considering the ABB EI813F, several related models may also meet specific needs. These include:

1. **ABB DI810** – A reliable model for digital I/O.

2. **ABB CI868K01-eA** – Offers enhanced communication capabilities.

3. **ABB PM861K01** – Best for power management applications.

4. **ABB CI855-1** – High-speed processing for demanding applications.

5. **ABB 12KM02E-V0002** – A robust option for modular I/O configurations.

6. **ABB 3HAC17484-8108** – Known for its reliability and extensive diagnostics.

7. **ABB SCYC51090** – Integrates seamlessly with control systems for monitoring.

8. **ABB UFC719AE101** – A versatile model for various industrial applications.

9. **ABB PPD113B01-10-150000** – Ideal for process automation scenarios.

10. **ABB EI802F** – A predecessor known for its reliable performance in similar applications.

**Conclusion**

In conclusion, the ABB EI813F stands as a versatile and powerful solution within the ABB automation products lineup. Its technical features, adaptability across various industrial applications, and robust performance make it an ideal choice for businesses looking to enhance their operational efficiency. With the ability to integrate seamlessly into existing systems, the EI813F not only meets the current demands of automation but also paves the way for future advancements in industrial technology. Whether you are in manufacturing, energy management, or process control, the ABB EI813F is designed to elevate your operations to new heights.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The ABB EI813F is engineered with a suite of technical features that cater to the needs of modern industrial environments. Key specifications include:

– **Modular Design**: The EI813F features a modular design, allowing for easy integration into existing systems while enabling future scalability. This modularity ensures that users can customize their configurations to fit specific operational requirements.

– **High-Speed Communication**: Equipped with advanced communication protocols, the ABB EI813F supports high-speed data transfer, ensuring real-time monitoring and control. This feature is critical for maintaining operational efficiency and reducing latency in data processing.

– **Versatile I/O Options**: The device supports a variety of input and output configurations. Whether dealing with digital or analog signals, the EI813F provides the flexibility needed for diverse applications, from process control to machine automation.

– **Robust Environmental Ratings**: Designed to withstand harsh industrial conditions, the EI813F has an IP rating that ensures protection against dust and moisture, making it suitable for various environments, including manufacturing plants, oil and gas facilities, and utility sectors.

– **User-Friendly Interface**: The intuitive interface simplifies setup and operation, allowing users to easily configure parameters and monitor system status. This usability is a significant advantage in minimizing training time and operational errors.

– **Integrated Diagnostics**: The ABB EI813F comes equipped with built-in diagnostic features that facilitate proactive maintenance, helping to reduce downtime and extend the lifespan of equipment.

**Usage Scenarios**

The ABB EI813F is versatile and can be applied across multiple industry sectors. Here are some practical usage scenarios:

1. **Manufacturing Automation**: The EI813F can be utilized in assembly lines for real-time monitoring of machinery performance, ensuring operational efficiency and minimizing production delays.

2. **Energy Management**: In power generation and distribution, the device can monitor energy consumption and analyze performance data to optimize grid operations.

3. **Process Control**: The EI813F is ideal for controlling various industrial processes, such as chemical production, where precise monitoring and control of variables like temperature and pressure are crucial.

4. **Building Management Systems**: In smart buildings, the device can be integrated into HVAC systems to optimize energy usage and enhance comfort levels for occupants.

5. **Transportation Systems**: The EI813F can be employed in automated traffic management systems to monitor vehicle flow and optimize signaling based on real-time data.

**Comparison with Other Models**

When comparing the ABB EI813F to other models in the ABB portfolio, such as the ABB DI810 and ABB CI868K01-eA, several distinctions emerge. The DI810 focuses primarily on digital inputs and outputs, making it suitable for applications requiring straightforward on/off control. In contrast, the EI813F offers a broader range of I/O options, including advanced analog capabilities, making it more versatile for complex applications.

Another model, the ABB PM861K01, is tailored for power management systems, providing comprehensive energy monitoring features. While the PM861K01 excels in energy management, the EI813F's modular design and high-speed communication make it a preferred choice for applications requiring extensive data integration and processing capabilities.

Additionally, the ABB CI855-1 is renowned for its high-speed processing, but it does not feature the same level of environmental protection as the EI813F. This makes the EI813F more suitable for demanding industrial environments where durability is key.

**Related Models**

For those considering the ABB EI813F, several related models may also meet specific needs. These include:

1. **ABB DI810** – A reliable model for digital I/O.

2. **ABB CI868K01-eA** – Offers enhanced communication capabilities.

3. **ABB PM861K01** – Best for power management applications.

4. **ABB CI855-1** – High-speed processing for demanding applications.

5. **ABB 12KM02E-V0002** – A robust option for modular I/O configurations.

6. **ABB 3HAC17484-8108** – Known for its reliability and extensive diagnostics.

7. **ABB SCYC51090** – Integrates seamlessly with control systems for monitoring.

8. **ABB UFC719AE101** – A versatile model for various industrial applications.

9. **ABB PPD113B01-10-150000** – Ideal for process automation scenarios.

10. **ABB EI802F** – A predecessor known for its reliable performance in similar applications.

**Conclusion**

In conclusion, the ABB EI813F stands as a versatile and powerful solution within the ABB automation products lineup. Its technical features, adaptability across various industrial applications, and robust performance make it an ideal choice for businesses looking to enhance their operational efficiency. With the ability to integrate seamlessly into existing systems, the EI813F not only meets the current demands of automation but also paves the way for future advancements in industrial technology. Whether you are in manufacturing, energy management, or process control, the ABB EI813F is designed to elevate your operations to new heights.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.