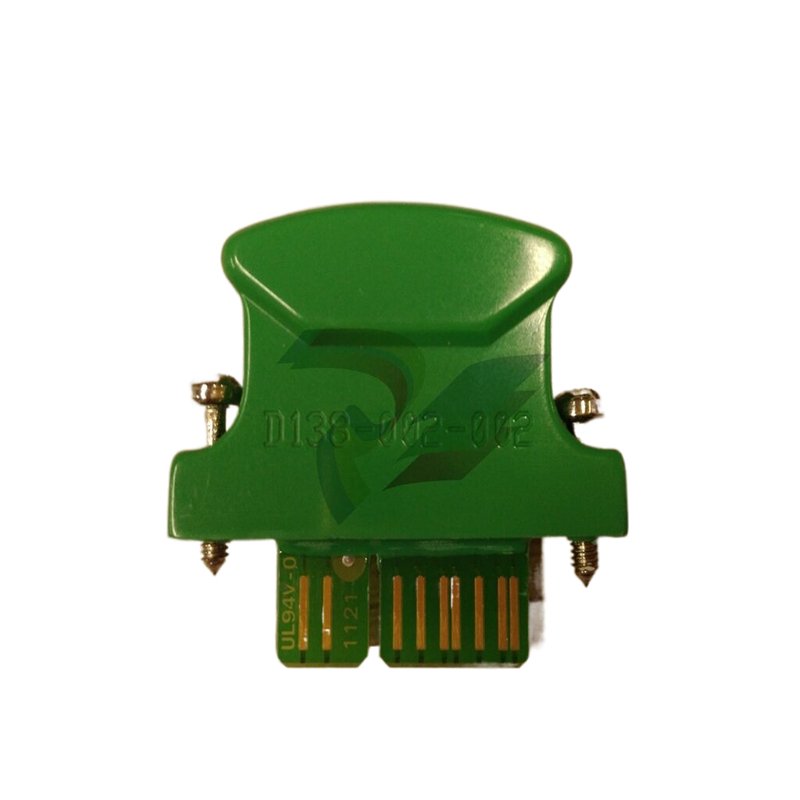

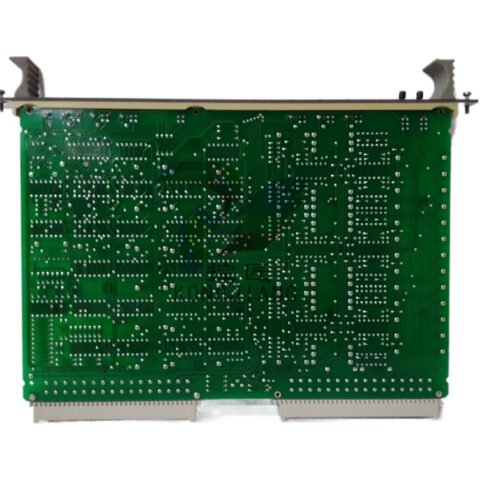

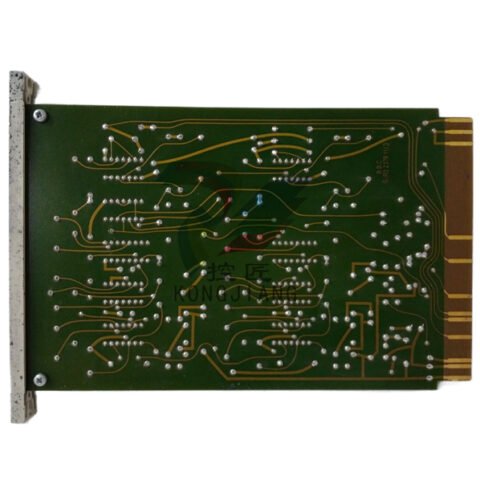

ABB IRB 4600 3HAC031936-001/03 3HNA012841-001/04 Cable Harness, Multibus

Introducing the ABB IRB 4600 3HAC031936-001/03 3HNA012841-001/04, a versatile and robust industrial robot designed to elevate your automation processes. The IRB 4600 series is engineered for high performance, precision, and reliability, making it an ideal choice for a wide range of applications in manufacturing, assembly, and material handling. With an impressive array of technical features, this model stands out in the ABB automation products lineup.

Key Technical Features

The ABB IRB 4600 boasts an impressive payload capacity of up to 60 kg and a reach of 2.55 meters, making it suitable for handling heavy components with ease. Its compact design allows for installation in tight spaces, optimizing your factory's layout. The robot features a high rigidity structure and advanced motion control, providing exceptional accuracy and repeatability of ±0.05 mm, ensuring that your operations run smoothly without the risk of errors.

Equipped with the latest generation ABB controller, the IRB 4600 offers enhanced programming capabilities and intuitive user interfaces, allowing for quick setup and operations. It supports both ABB's Rapid programming language and standard programming environments, making it adaptable to various applications. Furthermore, the robot's energy efficiency is a key highlight, reducing operational costs while maintaining high performance levels.

Usage Scenarios

The ABB IRB 4600 is designed for a diverse array of applications. In manufacturing, it excels in welding, painting, and assembly tasks, significantly improving productivity and quality. Its ability to handle complex manipulations makes it ideal for automotive assembly lines, where precision and speed are paramount.

In material handling scenarios, the IRB 4600 can efficiently manage logistics tasks such as palletizing, depalletizing, and transporting goods within a warehouse environment. The robot's ability to integrate seamlessly with existing systems, such as conveyor belts and automated storage solutions, enhances overall operational efficiency.

Another exciting application for the ABB IRB 4600 is in the realm of collaborative robotics. With appropriate safety measures in place, this industrial robot can work alongside human operators, enhancing workflows while ensuring safety. This collaborative capability makes it a perfect fit for small to medium-scale enterprises looking to integrate advanced automation while maintaining a human touch.

Comparison with Other Models

When comparing the ABB IRB 4600 with other models in the ABB robotics range, such as the IRB 2400 and IRB 2600, several distinctions become evident. The IRB 2400 is known for its versatility and is often favored for lighter tasks, with a lower payload capacity of 20 kg. In contrast, the IRB 2600, while offering slightly less reach than the IRB 4600, presents a similar payload capacity, making it well-suited for tasks requiring high speed and precision.

The ABB IRB 4600 excels where heavier payloads are involved and is designed for high-demand applications, making it a superior choice in scenarios that require robust handling capabilities. Compared to models like the ABB IRB 6700, which is designed for high payload situations up to 300 kg, the IRB 4600 strikes an excellent balance between payload capacity and reach, making it adaptable for various industrial needs without compromising on performance.

Related Models

In the ABB automation products portfolio, several related models complement the IRB 4600. These include:

1. **ABB IRB 6700**: A heavy-duty industrial robot designed for high payload applications.

2. **ABB IRB 2600**: A flexible robot ideal for medium payload tasks, known for its speed and precision.

3. **ABB IRB 2400**: A reliable model for light to medium payload applications, often used in assembly lines.

4. **ABB IRB 7600**: A large robot designed for heavy material handling and manufacturing tasks.

5. **ABB IRB 6700/120**: Another variant of the IRB 6700, optimized for complex applications requiring higher reach.

6. **ABB IRB 5500**: A compact model designed for precision tasks in tight spaces.

7. **ABB 07DC91**: A compact controller that enhances the performance of ABB robots, including integration options.

8. **ABB PM864AK01**: A powerful motion control module that can be paired with several ABB robots for increased functionality.

9. **ABB ACS880-01-246A-3**: A drive designed to work seamlessly with ABB robots for enhanced motion control.

10. **ABB PCD231**: A programmable controller that enhances the automation capabilities of ABB robots.

Conclusion

The ABB IRB 4600 3HAC031936-001/03 3HNA012841-001/04 stands as a testament to ABB's commitment to innovation in the field of industrial automation. With its blend of high payload capacity, compact design, and advanced programming capabilities, it is an indispensable addition to any manufacturing or material handling operation. Whether you are looking to boost your production line's efficiency or integrate collaborative robotics into your workflows, the IRB 4600 is designed to meet your needs head-on.

Explore the potential of ABB automation products with the IRB 4600 and elevate your operations to new heights of efficiency and performance. Embrace the future of industrial robotics and discover the transformative power of automation with ABB.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The ABB IRB 4600 boasts an impressive payload capacity of up to 60 kg and a reach of 2.55 meters, making it suitable for handling heavy components with ease. Its compact design allows for installation in tight spaces, optimizing your factory's layout. The robot features a high rigidity structure and advanced motion control, providing exceptional accuracy and repeatability of ±0.05 mm, ensuring that your operations run smoothly without the risk of errors.

Equipped with the latest generation ABB controller, the IRB 4600 offers enhanced programming capabilities and intuitive user interfaces, allowing for quick setup and operations. It supports both ABB's Rapid programming language and standard programming environments, making it adaptable to various applications. Furthermore, the robot's energy efficiency is a key highlight, reducing operational costs while maintaining high performance levels.

Usage Scenarios

The ABB IRB 4600 is designed for a diverse array of applications. In manufacturing, it excels in welding, painting, and assembly tasks, significantly improving productivity and quality. Its ability to handle complex manipulations makes it ideal for automotive assembly lines, where precision and speed are paramount.

In material handling scenarios, the IRB 4600 can efficiently manage logistics tasks such as palletizing, depalletizing, and transporting goods within a warehouse environment. The robot's ability to integrate seamlessly with existing systems, such as conveyor belts and automated storage solutions, enhances overall operational efficiency.

Another exciting application for the ABB IRB 4600 is in the realm of collaborative robotics. With appropriate safety measures in place, this industrial robot can work alongside human operators, enhancing workflows while ensuring safety. This collaborative capability makes it a perfect fit for small to medium-scale enterprises looking to integrate advanced automation while maintaining a human touch.

Comparison with Other Models

When comparing the ABB IRB 4600 with other models in the ABB robotics range, such as the IRB 2400 and IRB 2600, several distinctions become evident. The IRB 2400 is known for its versatility and is often favored for lighter tasks, with a lower payload capacity of 20 kg. In contrast, the IRB 2600, while offering slightly less reach than the IRB 4600, presents a similar payload capacity, making it well-suited for tasks requiring high speed and precision.

The ABB IRB 4600 excels where heavier payloads are involved and is designed for high-demand applications, making it a superior choice in scenarios that require robust handling capabilities. Compared to models like the ABB IRB 6700, which is designed for high payload situations up to 300 kg, the IRB 4600 strikes an excellent balance between payload capacity and reach, making it adaptable for various industrial needs without compromising on performance.

Related Models

In the ABB automation products portfolio, several related models complement the IRB 4600. These include:

1. **ABB IRB 6700**: A heavy-duty industrial robot designed for high payload applications.

2. **ABB IRB 2600**: A flexible robot ideal for medium payload tasks, known for its speed and precision.

3. **ABB IRB 2400**: A reliable model for light to medium payload applications, often used in assembly lines.

4. **ABB IRB 7600**: A large robot designed for heavy material handling and manufacturing tasks.

5. **ABB IRB 6700/120**: Another variant of the IRB 6700, optimized for complex applications requiring higher reach.

6. **ABB IRB 5500**: A compact model designed for precision tasks in tight spaces.

7. **ABB 07DC91**: A compact controller that enhances the performance of ABB robots, including integration options.

8. **ABB PM864AK01**: A powerful motion control module that can be paired with several ABB robots for increased functionality.

9. **ABB ACS880-01-246A-3**: A drive designed to work seamlessly with ABB robots for enhanced motion control.

10. **ABB PCD231**: A programmable controller that enhances the automation capabilities of ABB robots.

Conclusion

The ABB IRB 4600 3HAC031936-001/03 3HNA012841-001/04 stands as a testament to ABB's commitment to innovation in the field of industrial automation. With its blend of high payload capacity, compact design, and advanced programming capabilities, it is an indispensable addition to any manufacturing or material handling operation. Whether you are looking to boost your production line's efficiency or integrate collaborative robotics into your workflows, the IRB 4600 is designed to meet your needs head-on.

Explore the potential of ABB automation products with the IRB 4600 and elevate your operations to new heights of efficiency and performance. Embrace the future of industrial robotics and discover the transformative power of automation with ABB.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.