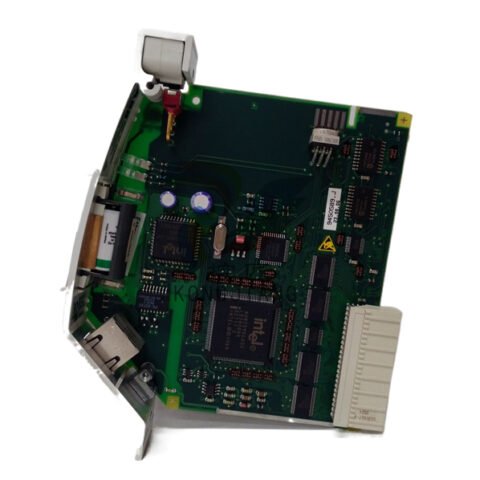

ABB IRB 6600/6650 3HAC033203-001 3HAC022286-001/06 DSQC679 Rotating AC Motor with Pinion

Introducing the ABB IRB 6600/6650 3HAC033203-001 3HAC022286-001/06 DSQC679, a cutting-edge industrial robot designed to elevate productivity and precision in manufacturing environments. This model combines advanced technology with robust engineering to deliver exceptional performance across a variety of applications.

Key Technical Features:

The ABB IRB 6600/6650 is powered by an innovative control system that ensures seamless operation and integration with existing automation frameworks. With a payload capacity ranging from 150 to 235 kg, it is ideal for handling heavy components and materials, making it suitable for industries such as automotive, metal fabrication, and consumer goods. The robot’s reach extends up to 2.6 meters, allowing it to cover large work areas with ease.

Equipped with ABB's proprietary Motion Control technology, the IRB 6600/6650 offers high-speed and precise movements, ensuring that tasks such as welding, material handling, and assembly are completed efficiently. The robot features a compact design, which allows for easy installation in confined spaces without compromising reach or performance. Additionally, it boasts an IP67 protection rating, making it resistant to dust and water, ensuring reliability in harsh production environments.

Usage Scenarios:

The ABB IRB 6600/6650 excels in a multitude of applications, making it a versatile choice for various industries. In automotive manufacturing, it can be utilized for tasks such as spot welding, part assembly, and palletizing. Its high payload capacity enables it to handle heavy automotive components with precision.

In the metal fabrication sector, the IRB 6600/6650 is an ideal solution for heavy-duty tasks like machining, grinding, and polishing. Its ability to operate in challenging environments enhances productivity and safety, reducing the need for human intervention in potentially hazardous operations.

Furthermore, in consumer goods manufacturing, this robot can streamline assembly lines by efficiently performing repetitive tasks such as packaging and sorting. Its flexibility allows for easy reprogramming, making it suitable for a variety of product lines and production schedules.

Comparison with Other Models:

When compared to other models in the ABB lineup, such as the ABB IRB 2400 and ABB IRB 2600, the IRB 6600/6650 stands out due to its superior payload capacity and reach. While the IRB 2400 is designed for lighter applications with a maximum payload of 20 kg, the IRB 6600/6650 caters to heavy-duty tasks with its robust build and higher weight capacity.

In contrast to the ABB IRB 6700, which is optimized for high-speed applications, the IRB 6600/6650 provides a balanced approach, combining speed with strength, making it suitable for both high-speed assembly and heavy lifting tasks. The IRB 6700 may excel in specific applications, but the IRB 6600/6650 offers versatility across a broader range of operations.

Related Models:

For those exploring ABB automation products, several related models complement the IRB 6600/6650. These include:

1. ABB IRB 2400 – Known for its versatility in lighter applications.

2. ABB IRB 6700 – A high-speed robot optimized for fast-paced environments.

3. ABB IRB 2600 – Offers a balance of speed and payload capacity for medium-duty tasks.

4. ABB IRB 6700 – Ideal for high-speed applications with a focus on precision.

5. ABB IRB 1600 – A compact robot for smaller tasks requiring agility.

6. ABB IRB 760 – Designed for handling heavier loads with a greater reach.

7. ABB IRB 5400 – Focused on welding and fabrication tasks.

8. ABB IRB 5500 – A heavy-duty robot that excels in challenging production environments.

9. ABB IRB 8700 – The ultimate in heavy payload capabilities for industrial applications.

10. ABB IRB 120 – A small robot for precise assembly and light handling.

In summary, the ABB IRB 6600/6650 3HAC033203-001 3HAC022286-001/06 DSQC679 represents a significant advancement in industrial robotics, combining high payload capacity, flexibility, and robust engineering to meet the demands of modern manufacturing. Whether you're looking to automate welding, material handling, or assembly tasks, this robot is equipped to enhance efficiency and productivity. Explore the potential of ABB automation products and find the perfect solution for your operational needs with the IRB 6600/6650.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The ABB IRB 6600/6650 is powered by an innovative control system that ensures seamless operation and integration with existing automation frameworks. With a payload capacity ranging from 150 to 235 kg, it is ideal for handling heavy components and materials, making it suitable for industries such as automotive, metal fabrication, and consumer goods. The robot’s reach extends up to 2.6 meters, allowing it to cover large work areas with ease.

Equipped with ABB's proprietary Motion Control technology, the IRB 6600/6650 offers high-speed and precise movements, ensuring that tasks such as welding, material handling, and assembly are completed efficiently. The robot features a compact design, which allows for easy installation in confined spaces without compromising reach or performance. Additionally, it boasts an IP67 protection rating, making it resistant to dust and water, ensuring reliability in harsh production environments.

Usage Scenarios:

The ABB IRB 6600/6650 excels in a multitude of applications, making it a versatile choice for various industries. In automotive manufacturing, it can be utilized for tasks such as spot welding, part assembly, and palletizing. Its high payload capacity enables it to handle heavy automotive components with precision.

In the metal fabrication sector, the IRB 6600/6650 is an ideal solution for heavy-duty tasks like machining, grinding, and polishing. Its ability to operate in challenging environments enhances productivity and safety, reducing the need for human intervention in potentially hazardous operations.

Furthermore, in consumer goods manufacturing, this robot can streamline assembly lines by efficiently performing repetitive tasks such as packaging and sorting. Its flexibility allows for easy reprogramming, making it suitable for a variety of product lines and production schedules.

Comparison with Other Models:

When compared to other models in the ABB lineup, such as the ABB IRB 2400 and ABB IRB 2600, the IRB 6600/6650 stands out due to its superior payload capacity and reach. While the IRB 2400 is designed for lighter applications with a maximum payload of 20 kg, the IRB 6600/6650 caters to heavy-duty tasks with its robust build and higher weight capacity.

In contrast to the ABB IRB 6700, which is optimized for high-speed applications, the IRB 6600/6650 provides a balanced approach, combining speed with strength, making it suitable for both high-speed assembly and heavy lifting tasks. The IRB 6700 may excel in specific applications, but the IRB 6600/6650 offers versatility across a broader range of operations.

Related Models:

For those exploring ABB automation products, several related models complement the IRB 6600/6650. These include:

1. ABB IRB 2400 – Known for its versatility in lighter applications.

2. ABB IRB 6700 – A high-speed robot optimized for fast-paced environments.

3. ABB IRB 2600 – Offers a balance of speed and payload capacity for medium-duty tasks.

4. ABB IRB 6700 – Ideal for high-speed applications with a focus on precision.

5. ABB IRB 1600 – A compact robot for smaller tasks requiring agility.

6. ABB IRB 760 – Designed for handling heavier loads with a greater reach.

7. ABB IRB 5400 – Focused on welding and fabrication tasks.

8. ABB IRB 5500 – A heavy-duty robot that excels in challenging production environments.

9. ABB IRB 8700 – The ultimate in heavy payload capabilities for industrial applications.

10. ABB IRB 120 – A small robot for precise assembly and light handling.

In summary, the ABB IRB 6600/6650 3HAC033203-001 3HAC022286-001/06 DSQC679 represents a significant advancement in industrial robotics, combining high payload capacity, flexibility, and robust engineering to meet the demands of modern manufacturing. Whether you're looking to automate welding, material handling, or assembly tasks, this robot is equipped to enhance efficiency and productivity. Explore the potential of ABB automation products and find the perfect solution for your operational needs with the IRB 6600/6650.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.