ABB IRB 6700 – 3HAC055435-001, 3HAC045063-001, 200/150, 3HAC045067-001 Industrial Robot

Introducing the ABB IRB 6700 – a powerful industrial robot that stands at the forefront of automation technology. With models 3HAC055435-001, 3HAC045063-001, 200/150, and 3HAC045067-001, the ABB IRB 6700 is engineered to deliver exceptional performance, versatility, and reliability for a wide range of applications across various industries.

**Key Technical Features**

The ABB IRB 6700 boasts a robust design and an array of advanced technical features that make it an ideal choice for demanding manufacturing environments. One of its standout specifications is its payload capacity, which varies across the models, enabling it to handle loads of up to 200 kg with unparalleled precision. The robot's reach is also impressive, with an effective working range that allows it to operate in confined spaces while maintaining efficiency.

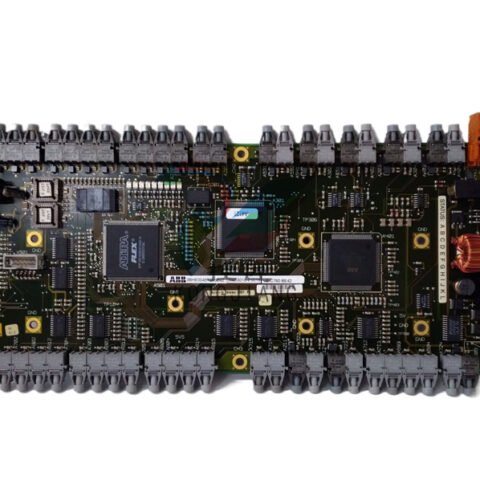

Equipped with the ABB OmniCore technology, the IRB 6700 offers enhanced motion control capabilities, ensuring smooth and accurate operations. Its advanced software, integrated with the ABB RobotStudio, enables easy programming and simulation, allowing operators to visualize tasks before execution. This capability not only saves time but also minimizes the risk of errors during operation.

The IRB 6700 is built for durability, featuring a rigid structure that can withstand harsh industrial conditions. Its IP67-rated protection ensures resistance to dust and water, making it suitable for applications in challenging environments such as metal fabrication, automotive assembly, and electronics manufacturing.

**Usage Scenarios**

The versatility of the ABB IRB 6700 makes it suitable for a variety of applications. In the automotive industry, it excels in tasks such as welding, painting, and material handling, where precision and speed are paramount. Its ability to work collaboratively with other automation products enhances overall production efficiency, allowing manufacturers to meet high output demands.

In the electronics sector, the IRB 6700 can be utilized for assembly processes, providing fine-tuned handling for delicate components. Its adaptability extends to packaging and palletizing applications, where the robot can manage repetitive tasks with consistent accuracy, reducing labor costs and increasing operational throughput.

Moreover, the IRB 6700 is ideal for industries focused on material handling and logistics. It can streamline warehouse operations by automating the movement of goods, ensuring timely deliveries, and optimizing space utilization. The robot's flexibility allows it to integrate seamlessly into existing workflows, enhancing overall productivity.

**Comparison with Other Models**

When compared to other models within the ABB family, such as the ABB IRB 2600 and ABB IRB 2400, the IRB 6700 stands out due to its higher payload capacity and extended reach. While the IRB 2600 is designed for medium payloads and compact spaces, the IRB 6700's robust structure allows it to handle heavier loads without compromising on speed or accuracy.

In contrast to the ABB IRB 140 Series, which is tailored for lighter applications, the IRB 6700 is engineered for more demanding tasks, making it a more suitable choice for industries that require greater versatility and strength. The advanced technology incorporated into the IRB 6700, such as the ABB OmniCore control system, also sets it apart from older models like the ABB 07DC91, providing users with enhanced programming capabilities and improved motion control.

**Related Models**

For those exploring the ABB automation products portfolio, several models complement the ABB IRB 6700, enhancing its functionality within various applications. The ABB IRB 2600, known for its agility and compact design, is perfect for tasks requiring speed and precision in limited spaces. The ABB IRB 2400, another reliable option, is tailored for various manufacturing processes with a focus on cost-effectiveness.

Additional related models include the ABB IRB 6700's sibling, the ABB IRB 6700-200/150, which shares similar capabilities but is optimized for slightly different applications. The ABB SC540 is a collaborative robot that works alongside human operators, making it an excellent choice for tasks that require human-robot interaction.

For those in need of advanced motion control, the ABB AC500 series can integrate seamlessly with the IRB 6700, providing an intelligent control system for complex tasks. Meanwhile, the ABB PCD231, with its versatile communication capabilities, enhances the connectivity of industrial systems.

Other noteworthy models in the ABB lineup include the ABB PM511V16, designed for process automation, and the ABB ACS880 series, which offers high-performance drives for motion control. The ABB TU852 S800 I/O provides essential input/output functions for various automation solutions, while the ABB DC551-CS31 is crucial for precise control in demanding applications.

**Conclusion**

The ABB IRB 6700 – models 3HAC055435-001, 3HAC045063-001, 200/150, and 3HAC045067-001 – represents a significant advancement in industrial automation technology. With its robust design, advanced motion control capabilities, and versatility across diverse applications, it stands as a top choice for companies looking to enhance their operational efficiency.

Whether you are in automotive manufacturing, electronics assembly, or logistics, the ABB IRB 6700 is engineered to meet the high demands of modern industries. Explore the possibilities of ABB automation products and take your production capabilities to new heights with the ABB IRB 6700.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The ABB IRB 6700 boasts a robust design and an array of advanced technical features that make it an ideal choice for demanding manufacturing environments. One of its standout specifications is its payload capacity, which varies across the models, enabling it to handle loads of up to 200 kg with unparalleled precision. The robot's reach is also impressive, with an effective working range that allows it to operate in confined spaces while maintaining efficiency.

Equipped with the ABB OmniCore technology, the IRB 6700 offers enhanced motion control capabilities, ensuring smooth and accurate operations. Its advanced software, integrated with the ABB RobotStudio, enables easy programming and simulation, allowing operators to visualize tasks before execution. This capability not only saves time but also minimizes the risk of errors during operation.

The IRB 6700 is built for durability, featuring a rigid structure that can withstand harsh industrial conditions. Its IP67-rated protection ensures resistance to dust and water, making it suitable for applications in challenging environments such as metal fabrication, automotive assembly, and electronics manufacturing.

**Usage Scenarios**

The versatility of the ABB IRB 6700 makes it suitable for a variety of applications. In the automotive industry, it excels in tasks such as welding, painting, and material handling, where precision and speed are paramount. Its ability to work collaboratively with other automation products enhances overall production efficiency, allowing manufacturers to meet high output demands.

In the electronics sector, the IRB 6700 can be utilized for assembly processes, providing fine-tuned handling for delicate components. Its adaptability extends to packaging and palletizing applications, where the robot can manage repetitive tasks with consistent accuracy, reducing labor costs and increasing operational throughput.

Moreover, the IRB 6700 is ideal for industries focused on material handling and logistics. It can streamline warehouse operations by automating the movement of goods, ensuring timely deliveries, and optimizing space utilization. The robot's flexibility allows it to integrate seamlessly into existing workflows, enhancing overall productivity.

**Comparison with Other Models**

When compared to other models within the ABB family, such as the ABB IRB 2600 and ABB IRB 2400, the IRB 6700 stands out due to its higher payload capacity and extended reach. While the IRB 2600 is designed for medium payloads and compact spaces, the IRB 6700's robust structure allows it to handle heavier loads without compromising on speed or accuracy.

In contrast to the ABB IRB 140 Series, which is tailored for lighter applications, the IRB 6700 is engineered for more demanding tasks, making it a more suitable choice for industries that require greater versatility and strength. The advanced technology incorporated into the IRB 6700, such as the ABB OmniCore control system, also sets it apart from older models like the ABB 07DC91, providing users with enhanced programming capabilities and improved motion control.

**Related Models**

For those exploring the ABB automation products portfolio, several models complement the ABB IRB 6700, enhancing its functionality within various applications. The ABB IRB 2600, known for its agility and compact design, is perfect for tasks requiring speed and precision in limited spaces. The ABB IRB 2400, another reliable option, is tailored for various manufacturing processes with a focus on cost-effectiveness.

Additional related models include the ABB IRB 6700's sibling, the ABB IRB 6700-200/150, which shares similar capabilities but is optimized for slightly different applications. The ABB SC540 is a collaborative robot that works alongside human operators, making it an excellent choice for tasks that require human-robot interaction.

For those in need of advanced motion control, the ABB AC500 series can integrate seamlessly with the IRB 6700, providing an intelligent control system for complex tasks. Meanwhile, the ABB PCD231, with its versatile communication capabilities, enhances the connectivity of industrial systems.

Other noteworthy models in the ABB lineup include the ABB PM511V16, designed for process automation, and the ABB ACS880 series, which offers high-performance drives for motion control. The ABB TU852 S800 I/O provides essential input/output functions for various automation solutions, while the ABB DC551-CS31 is crucial for precise control in demanding applications.

**Conclusion**

The ABB IRB 6700 – models 3HAC055435-001, 3HAC045063-001, 200/150, and 3HAC045067-001 – represents a significant advancement in industrial automation technology. With its robust design, advanced motion control capabilities, and versatility across diverse applications, it stands as a top choice for companies looking to enhance their operational efficiency.

Whether you are in automotive manufacturing, electronics assembly, or logistics, the ABB IRB 6700 is engineered to meet the high demands of modern industries. Explore the possibilities of ABB automation products and take your production capabilities to new heights with the ABB IRB 6700.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.