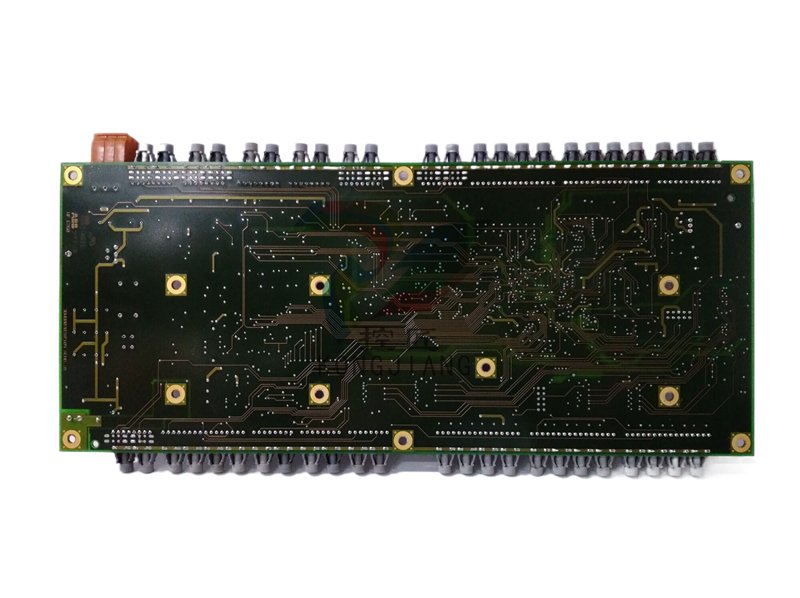

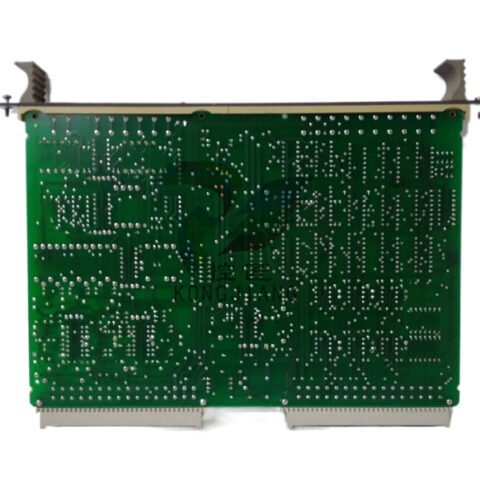

ABB MU200 Modular Device System – Comprehensive Control Solution

Introducing the ABB MU200, a cutting-edge solution designed to elevate your automation processes to new heights. As part of ABB's renowned line of automation products, the MU200 is engineered to meet the demands of modern industrial environments with precision, reliability, and efficiency.

Key Technical Features

The ABB MU200 is packed with advanced features that ensure optimal performance in various automation applications. One of the standout features of the MU200 is its robust processing power, which is supported by a high-speed communication interface. This allows for real-time data exchange and control, enhancing operational efficiency and enabling seamless integration with other ABB automation products.

The MU200 also boasts an intuitive user interface, which simplifies programming and operation. With support for multiple programming languages, including Ladder Diagram (LD) and Structured Text (ST), it caters to a wide range of user preferences. Moreover, its modular design allows for easy expansion and customization, enabling businesses to tailor the system to their specific needs.

In terms of connectivity, the ABB MU200 supports various communication protocols, including Ethernet/IP, Modbus TCP, and Profibus, ensuring compatibility with a broad spectrum of devices and systems. This versatility makes it an ideal choice for industries ranging from manufacturing to process control.

Usage Scenarios

The ABB MU200 shines in diverse applications across numerous industries. In manufacturing environments, it can be deployed for machine control, assembly line automation, and quality assurance processes. The real-time data processing capabilities of the MU200 ensure that any deviations from set parameters are instantly detected and corrected, which helps maintain product quality and reduce waste.

In process industries, such as oil and gas, chemical manufacturing, and food processing, the MU200 is invaluable for monitoring and controlling complex processes. Its ability to handle multiple I/O signals simultaneously makes it perfect for applications requiring precise control over various parameters, such as temperature, pressure, and flow rates.

Furthermore, the ABB MU200 is an excellent choice for building automation systems. It can manage HVAC systems, lighting controls, and security systems, providing energy efficiency and enhanced comfort in commercial buildings.

Comparison with Other Models

When comparing the ABB MU200 to other models within the ABB automation products range, its strengths become evident. For instance, while the ABB UNS1860B-P focuses on specific control applications, the MU200 offers greater versatility and adaptability, making it suitable for a wider array of tasks.

Compared to the ABB TU852 S800 I/O, which is primarily designed for distributed I/O systems, the MU200 provides a more comprehensive solution, integrating both control and monitoring functionalities within a single unit. Additionally, the modular nature of the MU200 allows for more straightforward upgrades and expansions than some older models, such as the ABB PM511V16.

For users requiring high-performance motion control, the ABB IRB 2400/1403/CR3 might be a consideration. However, the MU200 offers a more user-friendly interface and broader application suitability, making it a go-to choice for many automation projects.

Related Models

The ABB MU200 stands out not just on its own but also when placed alongside other notable models within the ABB ecosystem. Here are ten related models worth mentioning:

1. ABB UNS1860B-P: A focused solution for specific control applications.

2. ABB TU852 S800 I/O: Designed for distributed I/O systems.

3. ABB PM511V16: A reliable model for basic control functionalities.

4. ABB SDCS-PIN-51: Known for its advanced process control capabilities.

5. ABB ACS880-01-246A-3: A high-performance drive controller that complements the MU200.

6. ABB IRB 2600: A versatile industrial robot that can work in tandem with the MU200 for automated tasks.

7. ABB GINT5611C: A user-friendly interface for monitoring and control.

8. ABB YPP110A: A powerful controller for more advanced applications.

9. ABB 07DC91: A dependable digital controller for specific operations.

10. ABB 3HAC9398-1: A compact solution for various automation tasks.

In summary, the ABB MU200 represents the pinnacle of modern automation solutions. Its technical prowess, versatility in application, and user-friendly design make it an essential component for any business aiming to enhance its operational efficiency. Whether you're in manufacturing, process control, or building automation, the ABB MU200 is poised to deliver exceptional results, standing tall among other models in the ABB family. With its comprehensive feature set and seamless integration with existing systems, the MU200 is not just a product; it's a strategic investment in your automation future.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The ABB MU200 is packed with advanced features that ensure optimal performance in various automation applications. One of the standout features of the MU200 is its robust processing power, which is supported by a high-speed communication interface. This allows for real-time data exchange and control, enhancing operational efficiency and enabling seamless integration with other ABB automation products.

The MU200 also boasts an intuitive user interface, which simplifies programming and operation. With support for multiple programming languages, including Ladder Diagram (LD) and Structured Text (ST), it caters to a wide range of user preferences. Moreover, its modular design allows for easy expansion and customization, enabling businesses to tailor the system to their specific needs.

In terms of connectivity, the ABB MU200 supports various communication protocols, including Ethernet/IP, Modbus TCP, and Profibus, ensuring compatibility with a broad spectrum of devices and systems. This versatility makes it an ideal choice for industries ranging from manufacturing to process control.

Usage Scenarios

The ABB MU200 shines in diverse applications across numerous industries. In manufacturing environments, it can be deployed for machine control, assembly line automation, and quality assurance processes. The real-time data processing capabilities of the MU200 ensure that any deviations from set parameters are instantly detected and corrected, which helps maintain product quality and reduce waste.

In process industries, such as oil and gas, chemical manufacturing, and food processing, the MU200 is invaluable for monitoring and controlling complex processes. Its ability to handle multiple I/O signals simultaneously makes it perfect for applications requiring precise control over various parameters, such as temperature, pressure, and flow rates.

Furthermore, the ABB MU200 is an excellent choice for building automation systems. It can manage HVAC systems, lighting controls, and security systems, providing energy efficiency and enhanced comfort in commercial buildings.

Comparison with Other Models

When comparing the ABB MU200 to other models within the ABB automation products range, its strengths become evident. For instance, while the ABB UNS1860B-P focuses on specific control applications, the MU200 offers greater versatility and adaptability, making it suitable for a wider array of tasks.

Compared to the ABB TU852 S800 I/O, which is primarily designed for distributed I/O systems, the MU200 provides a more comprehensive solution, integrating both control and monitoring functionalities within a single unit. Additionally, the modular nature of the MU200 allows for more straightforward upgrades and expansions than some older models, such as the ABB PM511V16.

For users requiring high-performance motion control, the ABB IRB 2400/1403/CR3 might be a consideration. However, the MU200 offers a more user-friendly interface and broader application suitability, making it a go-to choice for many automation projects.

Related Models

The ABB MU200 stands out not just on its own but also when placed alongside other notable models within the ABB ecosystem. Here are ten related models worth mentioning:

1. ABB UNS1860B-P: A focused solution for specific control applications.

2. ABB TU852 S800 I/O: Designed for distributed I/O systems.

3. ABB PM511V16: A reliable model for basic control functionalities.

4. ABB SDCS-PIN-51: Known for its advanced process control capabilities.

5. ABB ACS880-01-246A-3: A high-performance drive controller that complements the MU200.

6. ABB IRB 2600: A versatile industrial robot that can work in tandem with the MU200 for automated tasks.

7. ABB GINT5611C: A user-friendly interface for monitoring and control.

8. ABB YPP110A: A powerful controller for more advanced applications.

9. ABB 07DC91: A dependable digital controller for specific operations.

10. ABB 3HAC9398-1: A compact solution for various automation tasks.

In summary, the ABB MU200 represents the pinnacle of modern automation solutions. Its technical prowess, versatility in application, and user-friendly design make it an essential component for any business aiming to enhance its operational efficiency. Whether you're in manufacturing, process control, or building automation, the ABB MU200 is poised to deliver exceptional results, standing tall among other models in the ABB family. With its comprehensive feature set and seamless integration with existing systems, the MU200 is not just a product; it's a strategic investment in your automation future.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.