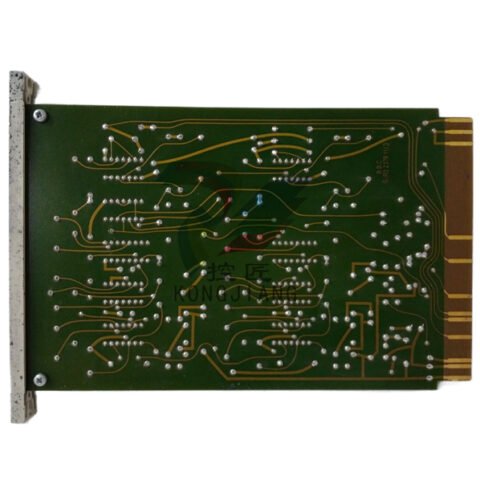

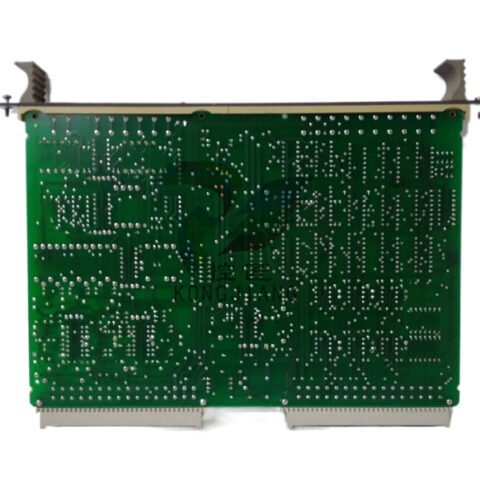

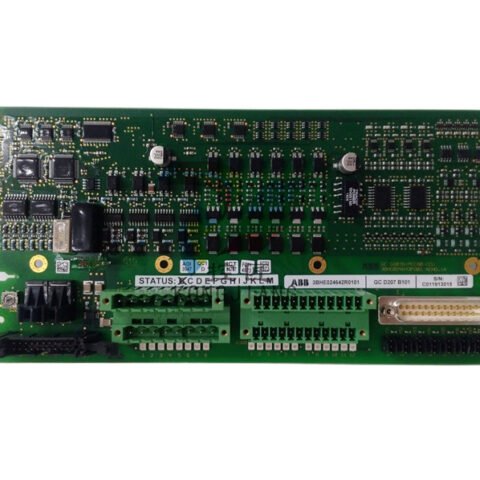

ABB PZ5002 GNT0153800R0001 Industrial Control Module

Introducing the ABB PZ5002 GNT0153800R0001: a pinnacle of innovation and reliability in the world of industrial automation. As part of ABB’s extensive range of automation products, this model embodies cutting-edge technology and robust engineering, designed to enhance productivity and streamline operations across various sectors.

**Key Technical Features**

The ABB PZ5002 GNT0153800R0001 is equipped with a powerful processing unit that ensures exceptional performance and responsiveness in data handling and control applications. With advanced communication protocols, including Ethernet/IP and Modbus TCP, this model facilitates seamless integration into existing systems, allowing for real-time monitoring and control. Its compatibility with a variety of sensors and actuators makes it an ideal choice for diverse industrial environments.

In terms of scalability, the ABB PZ5002 supports a modular design that enables easy expansion of functionalities as your operational needs grow. The unit features robust I/O capabilities, ensuring flexibility in connecting multiple devices without compromising performance. Additionally, the device is built with industrial-grade components, ensuring durability and reliability even in the most demanding conditions.

The PZ5002 incorporates intelligent diagnostic features that aid in predictive maintenance, reducing downtime and enhancing overall efficiency. This model also boasts a user-friendly interface, complete with an intuitive display and straightforward navigation, making it accessible for operators of varying skill levels.

**Usage Scenarios**

The versatility of the ABB PZ5002 GNT0153800R0001 allows it to be deployed across numerous applications. In manufacturing, it can serve as a central control unit for automated production lines, monitoring equipment performance and optimizing workflow. In the energy sector, it can be utilized for real-time data acquisition and control of renewable energy systems, ensuring maximum efficiency and minimal downtime.

Moreover, the ABB PZ5002 is ideal for process automation in industries such as chemicals, pharmaceuticals, and food and beverage. Its robust design and advanced features make it suitable for hazardous environments where safety and reliability are paramount. With its ability to interface with various field devices, it can easily adapt to existing setups, providing an immediate boost to operational efficiency.

**Comparison with Other Models**

When comparing the ABB PZ5002 GNT0153800R0001 with other models in the ABB automation products lineup, such as the ABB UNS1860B-P and the ABB PPE100A 3BHE037824R0101, it becomes clear that the PZ5002 offers superior processing power and flexibility. While the UNS1860B-P is geared towards specific applications within the S800 I/O architecture, the PZ5002 stands out with its broader range of compatibility and advanced communication options.

In contrast to the ABB TU852 S800 I/O and TU841 models, which are focused primarily on I/O control, the PZ5002 integrates control, monitoring, and diagnostics into one cohesive unit. The ABB PM511V16 3BSE011181R1, while also a reliable choice, lacks the advanced features and user-friendly interface that the PZ5002 offers, making the latter a more advantageous option for many users.

**Related Models**

For those exploring options within the ABB portfolio, the following models complement the ABB PZ5002 GNT0153800R0001 and cater to various automation needs:

1. ABB UNS1860B-P: Ideal for specific S800 I/O applications.

2. ABB PPE100A 3BHE037824R0101: A versatile controller with robust features.

3. ABB TU852 S800 I/O: Specializing in I/O control.

4. ABB TU841 – 3BSE020848R1: Another reliable I/O option.

5. ABB PM511V16 3BSE011181R1: A performance-driven automation controller.

6. ABB ACS880-01-246A-3 3ABD00035954-D: A powerful drive for various industrial applications.

7. ABB IRB 2400/1403/CR3: A robot designed for high-speed applications.

8. ABB SDCS-PIN-51 | 3BSE004940R1: A modern control system for precise monitoring.

9. ABB GINT5611C: A gateway for connecting devices and enhancing communication.

10. ABB 3HAC027569-001: A reliable automation component for diverse environments.

**Conclusion**

The ABB PZ5002 GNT0153800R0001 stands as a testament to ABB's commitment to providing high-quality automation products that meet the ever-evolving demands of industry. With its unparalleled performance, adaptability, and user-friendly design, the PZ5002 is poised to deliver significant improvements in efficiency and productivity across various applications.

Whether you are looking to upgrade your existing control systems or implement new automation solutions, the ABB PZ5002 GNT0153800R0001 offers a comprehensive solution that integrates seamlessly into any industrial environment. Embrace the future of automation with the ABB PZ5002 and experience the difference that advanced technology and innovative design can make.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The ABB PZ5002 GNT0153800R0001 is equipped with a powerful processing unit that ensures exceptional performance and responsiveness in data handling and control applications. With advanced communication protocols, including Ethernet/IP and Modbus TCP, this model facilitates seamless integration into existing systems, allowing for real-time monitoring and control. Its compatibility with a variety of sensors and actuators makes it an ideal choice for diverse industrial environments.

In terms of scalability, the ABB PZ5002 supports a modular design that enables easy expansion of functionalities as your operational needs grow. The unit features robust I/O capabilities, ensuring flexibility in connecting multiple devices without compromising performance. Additionally, the device is built with industrial-grade components, ensuring durability and reliability even in the most demanding conditions.

The PZ5002 incorporates intelligent diagnostic features that aid in predictive maintenance, reducing downtime and enhancing overall efficiency. This model also boasts a user-friendly interface, complete with an intuitive display and straightforward navigation, making it accessible for operators of varying skill levels.

**Usage Scenarios**

The versatility of the ABB PZ5002 GNT0153800R0001 allows it to be deployed across numerous applications. In manufacturing, it can serve as a central control unit for automated production lines, monitoring equipment performance and optimizing workflow. In the energy sector, it can be utilized for real-time data acquisition and control of renewable energy systems, ensuring maximum efficiency and minimal downtime.

Moreover, the ABB PZ5002 is ideal for process automation in industries such as chemicals, pharmaceuticals, and food and beverage. Its robust design and advanced features make it suitable for hazardous environments where safety and reliability are paramount. With its ability to interface with various field devices, it can easily adapt to existing setups, providing an immediate boost to operational efficiency.

**Comparison with Other Models**

When comparing the ABB PZ5002 GNT0153800R0001 with other models in the ABB automation products lineup, such as the ABB UNS1860B-P and the ABB PPE100A 3BHE037824R0101, it becomes clear that the PZ5002 offers superior processing power and flexibility. While the UNS1860B-P is geared towards specific applications within the S800 I/O architecture, the PZ5002 stands out with its broader range of compatibility and advanced communication options.

In contrast to the ABB TU852 S800 I/O and TU841 models, which are focused primarily on I/O control, the PZ5002 integrates control, monitoring, and diagnostics into one cohesive unit. The ABB PM511V16 3BSE011181R1, while also a reliable choice, lacks the advanced features and user-friendly interface that the PZ5002 offers, making the latter a more advantageous option for many users.

**Related Models**

For those exploring options within the ABB portfolio, the following models complement the ABB PZ5002 GNT0153800R0001 and cater to various automation needs:

1. ABB UNS1860B-P: Ideal for specific S800 I/O applications.

2. ABB PPE100A 3BHE037824R0101: A versatile controller with robust features.

3. ABB TU852 S800 I/O: Specializing in I/O control.

4. ABB TU841 – 3BSE020848R1: Another reliable I/O option.

5. ABB PM511V16 3BSE011181R1: A performance-driven automation controller.

6. ABB ACS880-01-246A-3 3ABD00035954-D: A powerful drive for various industrial applications.

7. ABB IRB 2400/1403/CR3: A robot designed for high-speed applications.

8. ABB SDCS-PIN-51 | 3BSE004940R1: A modern control system for precise monitoring.

9. ABB GINT5611C: A gateway for connecting devices and enhancing communication.

10. ABB 3HAC027569-001: A reliable automation component for diverse environments.

**Conclusion**

The ABB PZ5002 GNT0153800R0001 stands as a testament to ABB's commitment to providing high-quality automation products that meet the ever-evolving demands of industry. With its unparalleled performance, adaptability, and user-friendly design, the PZ5002 is poised to deliver significant improvements in efficiency and productivity across various applications.

Whether you are looking to upgrade your existing control systems or implement new automation solutions, the ABB PZ5002 GNT0153800R0001 offers a comprehensive solution that integrates seamlessly into any industrial environment. Embrace the future of automation with the ABB PZ5002 and experience the difference that advanced technology and innovative design can make.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.