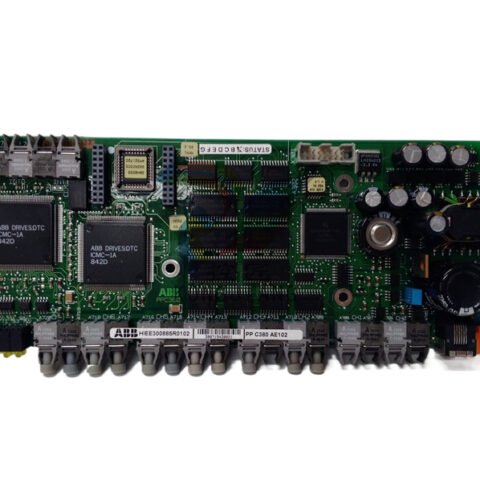

ABB TB805 Bus Outlet – Module Bus Extension Cable Adaptor, D-sub 25 Female, for Seamless Integration

Introducing the ABB TB805: A Cutting-Edge Solution for Modern Automation

Unlock the future of industrial automation with the ABB TB805, a highly advanced controller designed to meet the demands of contemporary manufacturing and process control environments. With its robust architecture, versatile functionality, and seamless integration capabilities, the ABB TB805 stands as a cornerstone in the ABB automation products lineup, ensuring reliability and efficiency for a multitude of applications.

Key Technical Features

The ABB TB805 is engineered with a suite of technical features that set it apart in the realm of industrial automation. At its core, the TB805 employs a powerful processing unit that supports high-speed data processing and real-time control, making it ideal for demanding applications that require precision and speed. Its extensive input/output (I/O) options provide flexibility in connecting a wide variety of sensors and actuators, allowing for comprehensive monitoring and control of processes.

In terms of connectivity, the ABB TB805 boasts multiple communication protocols, including Ethernet/IP, Modbus TCP, and Profibus, ensuring compatibility with an array of devices and systems. This interoperability is crucial for creating a cohesive automation ecosystem. The TB805 also features built-in security measures to protect against unauthorized access, safeguarding your critical operational data.

Another standout feature is the user-friendly interface, which simplifies programming and configuration. The controller supports ABB’s automation software, allowing users to create custom applications that can be tailored to specific operational needs. With support for advanced analytics and diagnostics, the TB805 enables operators to gain insights into system performance, contributing to improved efficiency and reduced downtime.

Usage Scenarios

The ABB TB805 is versatile enough to be deployed across a range of industries, including manufacturing, oil and gas, food and beverage, and pharmaceuticals. In manufacturing, the TB805 can streamline assembly line operations, offering precise control over robotic arms and conveyor systems. Its real-time data processing capabilities ensure that production schedules are met while maintaining high-quality standards.

In the oil and gas sector, the TB805 plays a vital role in monitoring and controlling complex processes such as drilling, refining, and distribution. Its ability to handle multiple I/O configurations allows for comprehensive oversight of equipment and environmental parameters, enhancing safety and operational efficiency.

In food and beverage processing, the TB805 can optimize production lines by regulating temperature, pressure, and flow rates, ensuring product consistency and compliance with industry regulations. Its advanced analytics capabilities can track key performance indicators, helping to identify areas for improvement and cost savings.

Comparison with Other Models

When comparing the ABB TB805 to other models in the ABB automation products range, such as the ABB TU852 S800 I/O and the ABB PM511V16, it becomes clear that the TB805 offers a more advanced processing capability and greater flexibility. While the TU852 is primarily focused on I/O expansion, the TB805 integrates control, communication, and analytics into a single platform.

Additionally, the ABB PM511V16, although robust, lacks the extensive connectivity options found in the TB805. The TB805's support for modern communication protocols allows for easier integration with existing systems and devices, making it a more future-proof choice for enterprises looking to enhance their automation capabilities.

For those who require even higher levels of integration and processing power, the ABB ACS880-01-246A-3 is another option, but it is tailored more toward drive control applications, whereas the TB805 provides a broader range of functionalities suitable for various automation scenarios.

Related Models

To provide a comprehensive view of the ABB automation products lineup, consider the following related models:

1. ABB UNS1860B-P: A high-performance controller for machine automation.

2. ABB PPE100A 3BHE037824R0101: A versatile power distribution unit suited for multiple applications.

3. ABB TU841 – 3BSE020848R1: An I/O module designed for distributed control systems.

4. ABB TB852 3BSC950263R1: A highly efficient controller for intricate automation tasks.

5. ABB PM864AK01 3BSE018161R1: An advanced controller designed for process automation.

6. ABB SDCS-PIN-51 | 3BSE004940R1: A robust solution for industrial process control.

7. ABB GINT5611C: A communication interface that enhances connectivity options.

8. ABB 3HAC16035-1: A flexible I/O unit for various automation applications.

9. ABB 3HBE012049R0101 UFD128A101: A high-performance controller for demanding industrial environments.

10. ABB DSQC352B: A motion control module that complements the TB805's capabilities.

Conclusion

The ABB TB805 is a game-changer in the world of industrial automation, offering unmatched performance and versatility. Its robust technical features, coupled with its ability to integrate seamlessly into existing systems, make it an ideal choice for businesses looking to enhance operational efficiency and reliability. Whether you're in manufacturing, oil and gas, or food and beverage, the ABB TB805 is designed to meet your automation needs head-on, paving the way for a smarter, more connected future.

As part of ABB's extensive portfolio of automation products, the TB805 not only simplifies the complexities of industrial processes but also empowers businesses to harness the full potential of automation technology. Choose the ABB TB805 for your next project and experience the difference that cutting-edge automation can make in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

Unlock the future of industrial automation with the ABB TB805, a highly advanced controller designed to meet the demands of contemporary manufacturing and process control environments. With its robust architecture, versatile functionality, and seamless integration capabilities, the ABB TB805 stands as a cornerstone in the ABB automation products lineup, ensuring reliability and efficiency for a multitude of applications.

Key Technical Features

The ABB TB805 is engineered with a suite of technical features that set it apart in the realm of industrial automation. At its core, the TB805 employs a powerful processing unit that supports high-speed data processing and real-time control, making it ideal for demanding applications that require precision and speed. Its extensive input/output (I/O) options provide flexibility in connecting a wide variety of sensors and actuators, allowing for comprehensive monitoring and control of processes.

In terms of connectivity, the ABB TB805 boasts multiple communication protocols, including Ethernet/IP, Modbus TCP, and Profibus, ensuring compatibility with an array of devices and systems. This interoperability is crucial for creating a cohesive automation ecosystem. The TB805 also features built-in security measures to protect against unauthorized access, safeguarding your critical operational data.

Another standout feature is the user-friendly interface, which simplifies programming and configuration. The controller supports ABB’s automation software, allowing users to create custom applications that can be tailored to specific operational needs. With support for advanced analytics and diagnostics, the TB805 enables operators to gain insights into system performance, contributing to improved efficiency and reduced downtime.

Usage Scenarios

The ABB TB805 is versatile enough to be deployed across a range of industries, including manufacturing, oil and gas, food and beverage, and pharmaceuticals. In manufacturing, the TB805 can streamline assembly line operations, offering precise control over robotic arms and conveyor systems. Its real-time data processing capabilities ensure that production schedules are met while maintaining high-quality standards.

In the oil and gas sector, the TB805 plays a vital role in monitoring and controlling complex processes such as drilling, refining, and distribution. Its ability to handle multiple I/O configurations allows for comprehensive oversight of equipment and environmental parameters, enhancing safety and operational efficiency.

In food and beverage processing, the TB805 can optimize production lines by regulating temperature, pressure, and flow rates, ensuring product consistency and compliance with industry regulations. Its advanced analytics capabilities can track key performance indicators, helping to identify areas for improvement and cost savings.

Comparison with Other Models

When comparing the ABB TB805 to other models in the ABB automation products range, such as the ABB TU852 S800 I/O and the ABB PM511V16, it becomes clear that the TB805 offers a more advanced processing capability and greater flexibility. While the TU852 is primarily focused on I/O expansion, the TB805 integrates control, communication, and analytics into a single platform.

Additionally, the ABB PM511V16, although robust, lacks the extensive connectivity options found in the TB805. The TB805's support for modern communication protocols allows for easier integration with existing systems and devices, making it a more future-proof choice for enterprises looking to enhance their automation capabilities.

For those who require even higher levels of integration and processing power, the ABB ACS880-01-246A-3 is another option, but it is tailored more toward drive control applications, whereas the TB805 provides a broader range of functionalities suitable for various automation scenarios.

Related Models

To provide a comprehensive view of the ABB automation products lineup, consider the following related models:

1. ABB UNS1860B-P: A high-performance controller for machine automation.

2. ABB PPE100A 3BHE037824R0101: A versatile power distribution unit suited for multiple applications.

3. ABB TU841 – 3BSE020848R1: An I/O module designed for distributed control systems.

4. ABB TB852 3BSC950263R1: A highly efficient controller for intricate automation tasks.

5. ABB PM864AK01 3BSE018161R1: An advanced controller designed for process automation.

6. ABB SDCS-PIN-51 | 3BSE004940R1: A robust solution for industrial process control.

7. ABB GINT5611C: A communication interface that enhances connectivity options.

8. ABB 3HAC16035-1: A flexible I/O unit for various automation applications.

9. ABB 3HBE012049R0101 UFD128A101: A high-performance controller for demanding industrial environments.

10. ABB DSQC352B: A motion control module that complements the TB805's capabilities.

Conclusion

The ABB TB805 is a game-changer in the world of industrial automation, offering unmatched performance and versatility. Its robust technical features, coupled with its ability to integrate seamlessly into existing systems, make it an ideal choice for businesses looking to enhance operational efficiency and reliability. Whether you're in manufacturing, oil and gas, or food and beverage, the ABB TB805 is designed to meet your automation needs head-on, paving the way for a smarter, more connected future.

As part of ABB's extensive portfolio of automation products, the TB805 not only simplifies the complexities of industrial processes but also empowers businesses to harness the full potential of automation technology. Choose the ABB TB805 for your next project and experience the difference that cutting-edge automation can make in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.