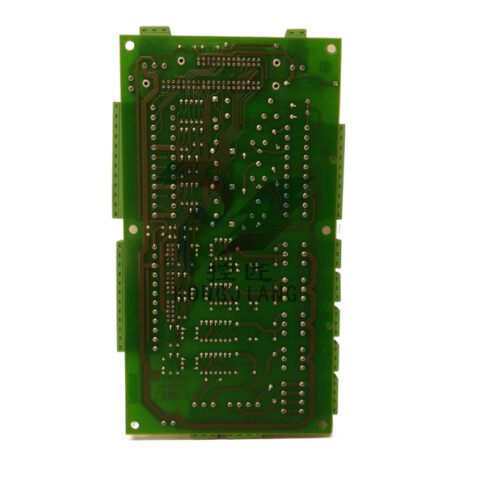

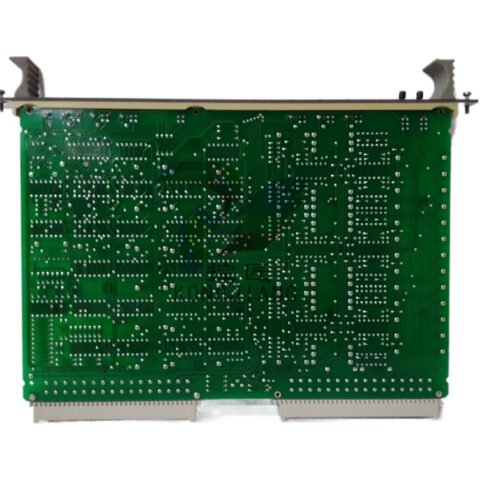

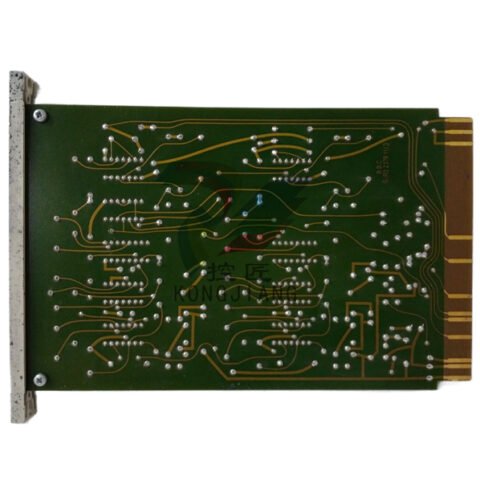

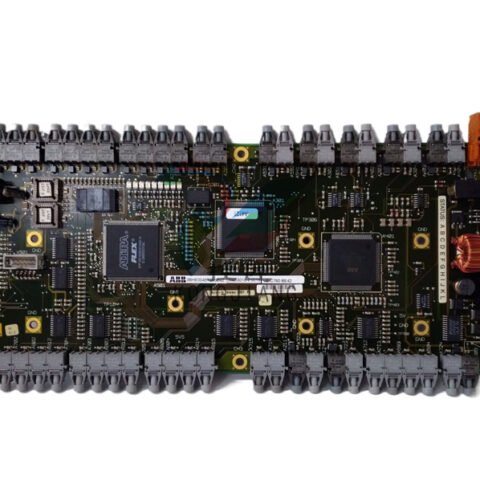

ABB TINT-6511 Modular Analog Input Terminal, Industrial Control Module

Introducing the ABB TINT-6511: A Pinnacle of Industrial Automation

In the realm of industrial automation, ABB has long been recognized for its commitment to innovation and excellence. The ABB TINT-6511 model is no exception. Designed to meet the demanding requirements of modern manufacturing and process control, this device combines advanced technology with user-friendly features, ensuring optimal performance in a variety of applications.

**Key Technical Features**

The ABB TINT-6511 boasts a robust set of technical features that set it apart in the competitive landscape of ABB automation products.

1. **High-Performance Processing**: Equipped with a powerful processor, the TINT-6511 enables rapid data processing and seamless communication between connected devices. This feature is crucial for applications requiring real-time monitoring and control.

2. **Versatile Input/Output Options**: The model offers a comprehensive range of I/O configurations, accommodating various sensors and actuators. This flexibility allows for easy integration into existing systems, making it an ideal choice for diverse industrial environments.

3. **User-Friendly Interface**: The TINT-6511 comes with an intuitive user interface that simplifies operation and configuration. Operators can easily navigate through settings, making adjustments with minimal training.

4. **Robust Communication Protocols**: Supporting multiple communication protocols, including Ethernet/IP and Modbus, the TINT-6511 ensures reliable connectivity across different devices and systems. This feature enhances interoperability, allowing for seamless integration with other ABB products and third-party components.

5. **Enhanced Safety Features**: Built with safety in mind, the ABB TINT-6511 includes advanced diagnostic capabilities and fault detection systems, ensuring optimal performance and minimizing downtime. This focus on safety aligns with ABB's dedication to creating secure industrial environments.

6. **Compact Design**: The model's space-saving design allows for easy installation in confined spaces, making it an excellent choice for facilities with limited room for equipment.

**Usage Scenarios**

The ABB TINT-6511 is versatile enough to be utilized across various industries and applications. Some common scenarios include:

– **Manufacturing**: In assembly lines, the TINT-6511 can facilitate automated processes, from material handling to quality control, ensuring efficiency and consistency.

– **Process Control**: The model excels in environments such as oil and gas refining, chemical processing, and water treatment plants, where reliable monitoring and control of various parameters are essential.

– **Building Automation**: The TINT-6511 is also suitable for HVAC systems, lighting control, and security systems within commercial buildings, making it a valuable asset in building management.

– **Robotics**: Integrated with robotic systems, the TINT-6511 can enhance precision and speed, improving overall productivity in tasks such as welding, painting, and assembly.

**Comparison with Other Models**

When compared to other models in the ABB lineup, the TINT-6511 stands out for its advanced processing capabilities and versatile I/O options. For instance, when compared to the ABB PM511V16 3BSE011181R1, which is known for its reliability in process control, the TINT-6511 offers superior connectivity options and a more user-friendly interface.

Unlike the ABB TU852 S800 I/O, which primarily focuses on providing I/O capabilities, the TINT-6511's processing power allows for more complex applications and integration with other automation products. Furthermore, compared to the ABB IRB 2600, a popular industrial robot, the TINT-6511 does not compete directly in terms of physical automation but complements it by enhancing control and data management capabilities.

Overall, the TINT-6511 provides a balanced solution that integrates seamlessly with a wide range of ABB automation products, making it a versatile choice for industries looking to elevate their operations.

**Related Models**

The ABB TINT-6511's features and capabilities can be appreciated further when viewed in the context of related models within the ABB portfolio. Some noteworthy references include:

1. **ABB UNS1860B-P**: A reliable model for basic automation tasks.

2. **ABB PPE100A 3BHE037824R0101**: Known for its excellent performance in power management.

3. **ABB TU841 – 3BSE020848R1**: A versatile I/O module that complements the TINT-6511.

4. **ABB GINT5611C**: Offers advanced networking capabilities for integrated automation solutions.

5. **ABB PM864AK01 3BSE018161R1**: Renowned for its high availability and redundancy features.

6. **ABB IRB 2400/1403/CR3**: A robust industrial robot that can be controlled with the TINT-6511.

7. **ABB DSQC352B**: A motion controller designed for high-performance applications.

8. **ABB 3HAC16035-1**: A fieldbus communication device that enhances connectivity.

9. **ABB ACS880-01-246A-3 3ABD00035954-D**: A drive that can work in tandem with the TINT-6511 for enhanced automation.

10. **ABB 3HNP04014-1**: A model known for its reliability in industrial applications.

**Conclusion**

The ABB TINT-6511 is a remarkable addition to ABB's extensive range of automation products. With its advanced features, flexibility in application, and user-friendly design, it is poised to enhance productivity and efficiency across various sectors. Whether you are looking to improve manufacturing processes, enhance building automation systems, or integrate robotics into your operations, the TINT-6511 is the reliable choice for your automation needs. Embrace the future of industrial automation with ABB TINT-6511, where innovation meets performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the realm of industrial automation, ABB has long been recognized for its commitment to innovation and excellence. The ABB TINT-6511 model is no exception. Designed to meet the demanding requirements of modern manufacturing and process control, this device combines advanced technology with user-friendly features, ensuring optimal performance in a variety of applications.

**Key Technical Features**

The ABB TINT-6511 boasts a robust set of technical features that set it apart in the competitive landscape of ABB automation products.

1. **High-Performance Processing**: Equipped with a powerful processor, the TINT-6511 enables rapid data processing and seamless communication between connected devices. This feature is crucial for applications requiring real-time monitoring and control.

2. **Versatile Input/Output Options**: The model offers a comprehensive range of I/O configurations, accommodating various sensors and actuators. This flexibility allows for easy integration into existing systems, making it an ideal choice for diverse industrial environments.

3. **User-Friendly Interface**: The TINT-6511 comes with an intuitive user interface that simplifies operation and configuration. Operators can easily navigate through settings, making adjustments with minimal training.

4. **Robust Communication Protocols**: Supporting multiple communication protocols, including Ethernet/IP and Modbus, the TINT-6511 ensures reliable connectivity across different devices and systems. This feature enhances interoperability, allowing for seamless integration with other ABB products and third-party components.

5. **Enhanced Safety Features**: Built with safety in mind, the ABB TINT-6511 includes advanced diagnostic capabilities and fault detection systems, ensuring optimal performance and minimizing downtime. This focus on safety aligns with ABB's dedication to creating secure industrial environments.

6. **Compact Design**: The model's space-saving design allows for easy installation in confined spaces, making it an excellent choice for facilities with limited room for equipment.

**Usage Scenarios**

The ABB TINT-6511 is versatile enough to be utilized across various industries and applications. Some common scenarios include:

– **Manufacturing**: In assembly lines, the TINT-6511 can facilitate automated processes, from material handling to quality control, ensuring efficiency and consistency.

– **Process Control**: The model excels in environments such as oil and gas refining, chemical processing, and water treatment plants, where reliable monitoring and control of various parameters are essential.

– **Building Automation**: The TINT-6511 is also suitable for HVAC systems, lighting control, and security systems within commercial buildings, making it a valuable asset in building management.

– **Robotics**: Integrated with robotic systems, the TINT-6511 can enhance precision and speed, improving overall productivity in tasks such as welding, painting, and assembly.

**Comparison with Other Models**

When compared to other models in the ABB lineup, the TINT-6511 stands out for its advanced processing capabilities and versatile I/O options. For instance, when compared to the ABB PM511V16 3BSE011181R1, which is known for its reliability in process control, the TINT-6511 offers superior connectivity options and a more user-friendly interface.

Unlike the ABB TU852 S800 I/O, which primarily focuses on providing I/O capabilities, the TINT-6511's processing power allows for more complex applications and integration with other automation products. Furthermore, compared to the ABB IRB 2600, a popular industrial robot, the TINT-6511 does not compete directly in terms of physical automation but complements it by enhancing control and data management capabilities.

Overall, the TINT-6511 provides a balanced solution that integrates seamlessly with a wide range of ABB automation products, making it a versatile choice for industries looking to elevate their operations.

**Related Models**

The ABB TINT-6511's features and capabilities can be appreciated further when viewed in the context of related models within the ABB portfolio. Some noteworthy references include:

1. **ABB UNS1860B-P**: A reliable model for basic automation tasks.

2. **ABB PPE100A 3BHE037824R0101**: Known for its excellent performance in power management.

3. **ABB TU841 – 3BSE020848R1**: A versatile I/O module that complements the TINT-6511.

4. **ABB GINT5611C**: Offers advanced networking capabilities for integrated automation solutions.

5. **ABB PM864AK01 3BSE018161R1**: Renowned for its high availability and redundancy features.

6. **ABB IRB 2400/1403/CR3**: A robust industrial robot that can be controlled with the TINT-6511.

7. **ABB DSQC352B**: A motion controller designed for high-performance applications.

8. **ABB 3HAC16035-1**: A fieldbus communication device that enhances connectivity.

9. **ABB ACS880-01-246A-3 3ABD00035954-D**: A drive that can work in tandem with the TINT-6511 for enhanced automation.

10. **ABB 3HNP04014-1**: A model known for its reliability in industrial applications.

**Conclusion**

The ABB TINT-6511 is a remarkable addition to ABB's extensive range of automation products. With its advanced features, flexibility in application, and user-friendly design, it is poised to enhance productivity and efficiency across various sectors. Whether you are looking to improve manufacturing processes, enhance building automation systems, or integrate robotics into your operations, the TINT-6511 is the reliable choice for your automation needs. Embrace the future of industrial automation with ABB TINT-6511, where innovation meets performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.