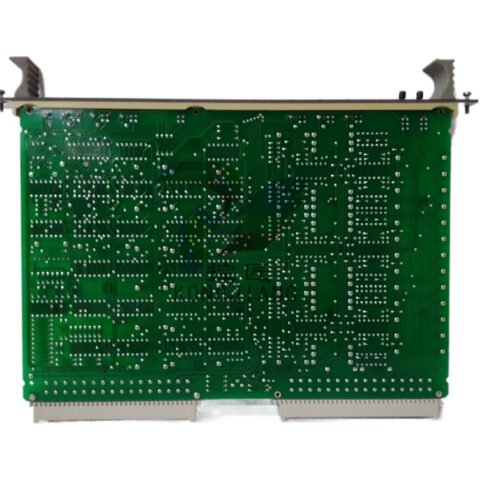

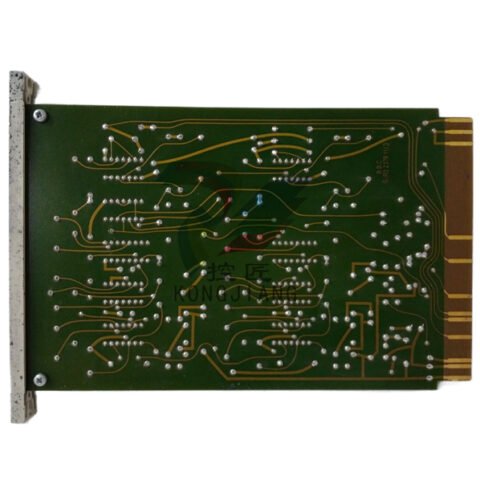

ABB TP830 PLC Module for Industrial Automation

Introducing the ABB TP830: Unleashing the Power of Advanced Automation

ABB, a global leader in industrial technology, continues its legacy of innovation with the ABB TP830, a cutting-edge automation product designed to optimize and enhance operational efficiency in various applications. This sophisticated piece of equipment is engineered with advanced features that cater to the complex demands of modern industries, ensuring seamless integration into existing systems while providing unparalleled performance.

Key Technical Features of the ABB TP830

The ABB TP830 stands out in the marketplace with its impressive array of technical features. At the core of its design is a robust processing unit that delivers high-speed performance, allowing for rapid data processing and real-time system responses. With a powerful microprocessor, the TP830 is capable of handling extensive input and output operations, making it ideal for large-scale industrial setups.

One of the defining characteristics of the ABB TP830 is its exceptional communication capabilities. Equipped with multiple communication protocols, including TCP/IP, Modbus, and Profibus, the TP830 ensures reliable data exchange between various components of the automation ecosystem. This flexibility is crucial for companies looking to integrate their systems with existing networks or expand their automation infrastructure.

The TP830 also features a user-friendly interface with an intuitive graphical display, simplifying the monitoring and control of processes. Users can easily navigate through the system, configure settings, and visualize operational data, thereby enhancing user experience and reducing training time.

Additionally, the ABB TP830 is built for resilience. Its rugged design meets international standards for industrial equipment, ensuring reliability even in harsh operating environments. With an extended temperature range and robust housing, the TP830 is suited for applications in factories, power plants, and other demanding settings.

Usage Scenarios for the ABB TP830

The versatility of the ABB TP830 makes it suitable for a wide range of applications. In manufacturing, it can be used to monitor and control production lines, enabling real-time adjustments that optimize throughput and reduce downtime. The TP830’s ability to process data quickly allows for predictive maintenance, identifying potential issues before they escalate into costly failures.

In the energy sector, the ABB TP830 plays a vital role in the management of power distribution systems. Its advanced communication capabilities facilitate seamless integration with other ABB automation products, enabling utilities to monitor grid performance, manage loads, and respond swiftly to outages.

In the oil and gas industry, the TP830 is instrumental in enhancing operational efficiency and safety. It can be deployed in drilling operations, where real-time data acquisition and processing are critical for decision-making. The robust design of the TP830 ensures it can operate reliably in extreme conditions, providing consistent performance that is vital for mission-critical applications.

Comparison with Other Models

When comparing the ABB TP830 to other models in the ABB portfolio, such as the ABB DI810 and ABB PM861K01, it becomes clear that the TP830 offers unique advantages. While the DI810 is primarily focused on digital input and output operations, the TP830 provides a more comprehensive solution with its enhanced processing power and communication capabilities.

In contrast to the ABB PM861K01, which is tailored for specific control applications, the TP830 serves as a versatile platform that can adapt to various industrial needs. Its ability to handle complex data and integrate with multiple communication protocols places it ahead in terms of flexibility and scalability.

Related Models

The ABB TP830 is part of a broader family of automation products that includes a variety of models designed for specific functions. Some related models worth mentioning include:

1. ABB DI810 – A digital input module designed for collecting binary signals.

2. ABB PM861K01 – A specialized control module for power management applications.

3. ABB CI868K01-eA – A communication interface designed for integration with other systems.

4. ABB 216NG63A – A general-purpose controller suitable for a range of applications.

5. ABB 12KM02E-V0002 – A module focused on fieldbus communication.

6. ABB 57160001-KX – A controller designed for enhanced processing capabilities.

7. ABB DSQC202 – A digital servo controller for robotics.

8. ABB UFC719AE101 – A universal field controller for diverse industrial applications.

9. ABB TP857 – A versatile processing unit similar to the TP830, but with different specifications.

10. ABB 5SHY6545L0001 AC10272001R0101 – An advanced automation component focused on motor control.

By positioning the ABB TP830 alongside these related models, users can see the breadth of options available within the ABB automation products lineup, allowing them to choose the best fit for their specific needs.

Conclusion

In conclusion, the ABB TP830 is a powerful automation product that embodies ABB's commitment to innovation and excellence in industrial technology. With its advanced technical features, flexible usage scenarios, and robust design, it is poised to meet the demands of today's dynamic industrial landscape. By investing in the ABB TP830, businesses can enhance operational efficiency, reduce downtime, and improve overall productivity.

As industries continue to evolve, the ABB TP830 stands ready to support organizations in their automation journey. Whether in manufacturing, energy, or any other sector, the ABB TP830 is the ideal solution for those seeking to leverage the latest advancements in automation technology. Embrace the future of automation with the ABB TP830 and experience the difference it can make in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

ABB, a global leader in industrial technology, continues its legacy of innovation with the ABB TP830, a cutting-edge automation product designed to optimize and enhance operational efficiency in various applications. This sophisticated piece of equipment is engineered with advanced features that cater to the complex demands of modern industries, ensuring seamless integration into existing systems while providing unparalleled performance.

Key Technical Features of the ABB TP830

The ABB TP830 stands out in the marketplace with its impressive array of technical features. At the core of its design is a robust processing unit that delivers high-speed performance, allowing for rapid data processing and real-time system responses. With a powerful microprocessor, the TP830 is capable of handling extensive input and output operations, making it ideal for large-scale industrial setups.

One of the defining characteristics of the ABB TP830 is its exceptional communication capabilities. Equipped with multiple communication protocols, including TCP/IP, Modbus, and Profibus, the TP830 ensures reliable data exchange between various components of the automation ecosystem. This flexibility is crucial for companies looking to integrate their systems with existing networks or expand their automation infrastructure.

The TP830 also features a user-friendly interface with an intuitive graphical display, simplifying the monitoring and control of processes. Users can easily navigate through the system, configure settings, and visualize operational data, thereby enhancing user experience and reducing training time.

Additionally, the ABB TP830 is built for resilience. Its rugged design meets international standards for industrial equipment, ensuring reliability even in harsh operating environments. With an extended temperature range and robust housing, the TP830 is suited for applications in factories, power plants, and other demanding settings.

Usage Scenarios for the ABB TP830

The versatility of the ABB TP830 makes it suitable for a wide range of applications. In manufacturing, it can be used to monitor and control production lines, enabling real-time adjustments that optimize throughput and reduce downtime. The TP830’s ability to process data quickly allows for predictive maintenance, identifying potential issues before they escalate into costly failures.

In the energy sector, the ABB TP830 plays a vital role in the management of power distribution systems. Its advanced communication capabilities facilitate seamless integration with other ABB automation products, enabling utilities to monitor grid performance, manage loads, and respond swiftly to outages.

In the oil and gas industry, the TP830 is instrumental in enhancing operational efficiency and safety. It can be deployed in drilling operations, where real-time data acquisition and processing are critical for decision-making. The robust design of the TP830 ensures it can operate reliably in extreme conditions, providing consistent performance that is vital for mission-critical applications.

Comparison with Other Models

When comparing the ABB TP830 to other models in the ABB portfolio, such as the ABB DI810 and ABB PM861K01, it becomes clear that the TP830 offers unique advantages. While the DI810 is primarily focused on digital input and output operations, the TP830 provides a more comprehensive solution with its enhanced processing power and communication capabilities.

In contrast to the ABB PM861K01, which is tailored for specific control applications, the TP830 serves as a versatile platform that can adapt to various industrial needs. Its ability to handle complex data and integrate with multiple communication protocols places it ahead in terms of flexibility and scalability.

Related Models

The ABB TP830 is part of a broader family of automation products that includes a variety of models designed for specific functions. Some related models worth mentioning include:

1. ABB DI810 – A digital input module designed for collecting binary signals.

2. ABB PM861K01 – A specialized control module for power management applications.

3. ABB CI868K01-eA – A communication interface designed for integration with other systems.

4. ABB 216NG63A – A general-purpose controller suitable for a range of applications.

5. ABB 12KM02E-V0002 – A module focused on fieldbus communication.

6. ABB 57160001-KX – A controller designed for enhanced processing capabilities.

7. ABB DSQC202 – A digital servo controller for robotics.

8. ABB UFC719AE101 – A universal field controller for diverse industrial applications.

9. ABB TP857 – A versatile processing unit similar to the TP830, but with different specifications.

10. ABB 5SHY6545L0001 AC10272001R0101 – An advanced automation component focused on motor control.

By positioning the ABB TP830 alongside these related models, users can see the breadth of options available within the ABB automation products lineup, allowing them to choose the best fit for their specific needs.

Conclusion

In conclusion, the ABB TP830 is a powerful automation product that embodies ABB's commitment to innovation and excellence in industrial technology. With its advanced technical features, flexible usage scenarios, and robust design, it is poised to meet the demands of today's dynamic industrial landscape. By investing in the ABB TP830, businesses can enhance operational efficiency, reduce downtime, and improve overall productivity.

As industries continue to evolve, the ABB TP830 stands ready to support organizations in their automation journey. Whether in manufacturing, energy, or any other sector, the ABB TP830 is the ideal solution for those seeking to leverage the latest advancements in automation technology. Embrace the future of automation with the ABB TP830 and experience the difference it can make in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.