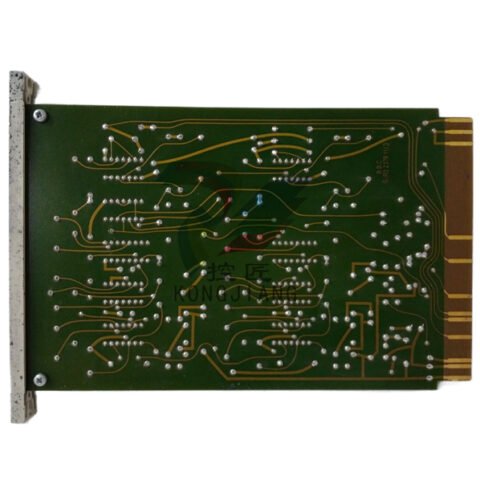

ABB UF C911 B108 Frequency Converter Accessories, Designed for Precision Control

Introducing the ABB UF C911 B108 – a pinnacle of innovation and reliability in the realm of industrial automation. With its advanced technology and robust design, the ABB UF C911 B108 is engineered to meet the demanding requirements of modern manufacturing environments, making it an indispensable asset for businesses seeking efficiency and precision in their operations.

**Key Technical Features**

The ABB UF C911 B108 is designed with cutting-edge features that set it apart from traditional automation solutions. Equipped with a high-performance processor, this unit ensures rapid data processing and seamless integration with various industrial systems. It supports multiple communication protocols, including Ethernet/IP, Modbus, and CANopen, allowing for versatile connectivity options tailored to your specific requirements.

Furthermore, the ABB UF C911 B108 boasts an extensive range of I/O options, enabling it to interface with numerous sensors and actuators. This flexibility allows for the customization of control schemes to optimize processes across diverse applications, from assembly lines to complex automated systems. The device also features built-in diagnostic tools, ensuring easy troubleshooting and maintenance, which minimizes downtime and maximizes productivity.

With a compact design, the ABB UF C911 B108 can be easily integrated into existing systems without requiring extensive modifications. This adaptability is complemented by its robust construction, designed to withstand harsh industrial conditions, making it suitable for use in environments with high levels of dust, moisture, or temperature fluctuations.

**Usage Scenarios**

The ABB UF C911 B108 excels in various industrial applications, making it an ideal choice for manufacturers across multiple sectors. In automotive assembly lines, the device can be used to control robotic arms and conveyor belts, ensuring precise coordination and timing to enhance production efficiency. In the food and beverage industry, it can monitor temperature and humidity levels, ensuring compliance with safety standards while optimizing product quality.

Another significant application is in material handling systems, where the ABB UF C911 B108 can manage automated storage and retrieval systems (AS/RS). Its ability to communicate with various sensors and actuators allows for real-time monitoring and control, resulting in improved inventory management and reduced operational costs.

In energy management systems, the ABB UF C911 B108 can facilitate real-time data collection and monitoring, enabling companies to optimize energy consumption and reduce costs. Its versatility extends to process automation in chemical and pharmaceutical industries, where precise control over variables such as temperature, pressure, and flow is crucial for product quality and safety.

**Comparison with Other Models**

When comparing the ABB UF C911 B108 to other models within the ABB automation products portfolio, such as the ABB UNS1860B-P and ABB TU852 S800 I/O, the UF C911 B108 stands out due to its superior processing power and extensive I/O capabilities. While the UNS1860B-P is designed primarily for specific applications, the UF C911 B108 offers broader applicability across various sectors, providing greater flexibility for businesses looking to streamline their automation processes.

Compared to the ABB TU841, which is tailored for modular systems, the ABB UF C911 B108 provides a more integrated solution, allowing for rapid deployment and reduced integration complexity. Furthermore, the built-in diagnostic tools of the UF C911 B108 enhance usability, making it easier for operators to monitor system performance and troubleshoot issues as they arise.

For companies that require high levels of customization, the ABB PM511V16 and ABB DC551-CS31 are also noteworthy mentions. However, the ease of integration and versatility of the ABB UF C911 B108 makes it a more favorable option for organizations seeking a balance between performance and adaptability.

**Related Models**

The ABB UF C911 B108 is part of a comprehensive suite of ABB automation products that cater to various industrial needs. Here are ten related models that complement the UF C911 B108 and enhance overall automation capabilities:

1. ABB UNS1860B-P – Ideal for specific applications needing robust communication.

2. ABB TU852 S800 I/O – A modular I/O solution for flexible system design.

3. ABB PM511V16 – A versatile power management unit for energy optimization.

4. ABB DC551-CS31 – Designed for complex control applications.

5. ABB 07DC91 – A reliable controller for streamlined operations.

6. ABB IRB 2600 – A high-performance industrial robot for precision tasks.

7. ABB ACS880-01-246A-3 – An advanced drive for energy efficiency and control.

8. ABB SDCS-PIN-51 – A powerful controller for process automation.

9. ABB PCD231 – A compact controller for small-scale automation.

10. ABB TU841 – A modular system suitable for various applications.

**Conclusion**

In summary, the ABB UF C911 B108 represents a significant advancement in industrial automation, combining robust performance, flexibility, and ease of integration. Its comprehensive feature set and adaptability make it an essential tool for manufacturers aiming to enhance operational efficiency and product quality. Whether in automotive, food processing, material handling, or energy management, the ABB UF C911 B108 stands out as a cornerstone of modern automation solutions.

Investing in the ABB UF C911 B108 means choosing a future-proof solution that aligns with the evolving landscape of industrial automation, ensuring your business remains competitive in an increasingly automated world. Discover the potential of ABB automation products and elevate your operations with the ABB UF C911 B108 today.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The ABB UF C911 B108 is designed with cutting-edge features that set it apart from traditional automation solutions. Equipped with a high-performance processor, this unit ensures rapid data processing and seamless integration with various industrial systems. It supports multiple communication protocols, including Ethernet/IP, Modbus, and CANopen, allowing for versatile connectivity options tailored to your specific requirements.

Furthermore, the ABB UF C911 B108 boasts an extensive range of I/O options, enabling it to interface with numerous sensors and actuators. This flexibility allows for the customization of control schemes to optimize processes across diverse applications, from assembly lines to complex automated systems. The device also features built-in diagnostic tools, ensuring easy troubleshooting and maintenance, which minimizes downtime and maximizes productivity.

With a compact design, the ABB UF C911 B108 can be easily integrated into existing systems without requiring extensive modifications. This adaptability is complemented by its robust construction, designed to withstand harsh industrial conditions, making it suitable for use in environments with high levels of dust, moisture, or temperature fluctuations.

**Usage Scenarios**

The ABB UF C911 B108 excels in various industrial applications, making it an ideal choice for manufacturers across multiple sectors. In automotive assembly lines, the device can be used to control robotic arms and conveyor belts, ensuring precise coordination and timing to enhance production efficiency. In the food and beverage industry, it can monitor temperature and humidity levels, ensuring compliance with safety standards while optimizing product quality.

Another significant application is in material handling systems, where the ABB UF C911 B108 can manage automated storage and retrieval systems (AS/RS). Its ability to communicate with various sensors and actuators allows for real-time monitoring and control, resulting in improved inventory management and reduced operational costs.

In energy management systems, the ABB UF C911 B108 can facilitate real-time data collection and monitoring, enabling companies to optimize energy consumption and reduce costs. Its versatility extends to process automation in chemical and pharmaceutical industries, where precise control over variables such as temperature, pressure, and flow is crucial for product quality and safety.

**Comparison with Other Models**

When comparing the ABB UF C911 B108 to other models within the ABB automation products portfolio, such as the ABB UNS1860B-P and ABB TU852 S800 I/O, the UF C911 B108 stands out due to its superior processing power and extensive I/O capabilities. While the UNS1860B-P is designed primarily for specific applications, the UF C911 B108 offers broader applicability across various sectors, providing greater flexibility for businesses looking to streamline their automation processes.

Compared to the ABB TU841, which is tailored for modular systems, the ABB UF C911 B108 provides a more integrated solution, allowing for rapid deployment and reduced integration complexity. Furthermore, the built-in diagnostic tools of the UF C911 B108 enhance usability, making it easier for operators to monitor system performance and troubleshoot issues as they arise.

For companies that require high levels of customization, the ABB PM511V16 and ABB DC551-CS31 are also noteworthy mentions. However, the ease of integration and versatility of the ABB UF C911 B108 makes it a more favorable option for organizations seeking a balance between performance and adaptability.

**Related Models**

The ABB UF C911 B108 is part of a comprehensive suite of ABB automation products that cater to various industrial needs. Here are ten related models that complement the UF C911 B108 and enhance overall automation capabilities:

1. ABB UNS1860B-P – Ideal for specific applications needing robust communication.

2. ABB TU852 S800 I/O – A modular I/O solution for flexible system design.

3. ABB PM511V16 – A versatile power management unit for energy optimization.

4. ABB DC551-CS31 – Designed for complex control applications.

5. ABB 07DC91 – A reliable controller for streamlined operations.

6. ABB IRB 2600 – A high-performance industrial robot for precision tasks.

7. ABB ACS880-01-246A-3 – An advanced drive for energy efficiency and control.

8. ABB SDCS-PIN-51 – A powerful controller for process automation.

9. ABB PCD231 – A compact controller for small-scale automation.

10. ABB TU841 – A modular system suitable for various applications.

**Conclusion**

In summary, the ABB UF C911 B108 represents a significant advancement in industrial automation, combining robust performance, flexibility, and ease of integration. Its comprehensive feature set and adaptability make it an essential tool for manufacturers aiming to enhance operational efficiency and product quality. Whether in automotive, food processing, material handling, or energy management, the ABB UF C911 B108 stands out as a cornerstone of modern automation solutions.

Investing in the ABB UF C911 B108 means choosing a future-proof solution that aligns with the evolving landscape of industrial automation, ensuring your business remains competitive in an increasingly automated world. Discover the potential of ABB automation products and elevate your operations with the ABB UF C911 B108 today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.