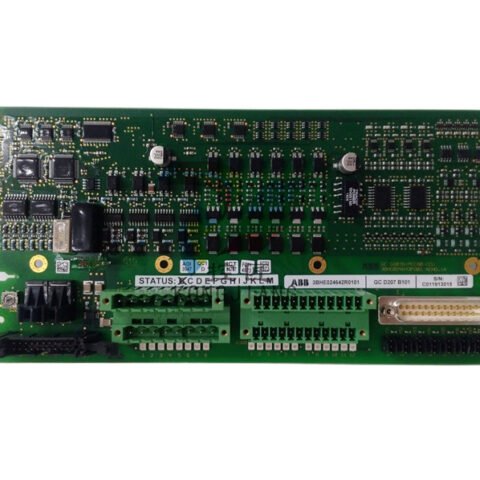

ABB YPK107 Communication Unit – Reliable Industrial Networking Solution

Introducing the ABB YPK107: A Cutting-Edge Solution in ABB Automation Products

The ABB YPK107 stands out in the extensive portfolio of ABB automation products, designed to optimize performance in various industrial applications. With its robust technical features and innovative design, the YPK107 is engineered to meet the evolving needs of modern automation environments.

Key Technical Features

The ABB YPK107 is distinguished by its advanced performance specifications and versatility. Key features include:

1. **High Processing Speed**: Equipped with a powerful processor, the YPK107 delivers rapid data processing capabilities, enabling real-time decision-making in complex automation systems. This feature ensures minimal latency, which is critical in high-speed manufacturing environments.

2. **Flexible Communication Protocols**: The YPK107 supports multiple communication protocols, including Ethernet/IP, PROFINET, and Modbus. This flexibility allows seamless integration with various devices and systems, enhancing interoperability across different platforms.

3. **Robust I/O Capacity**: The model boasts an extensive range of input/output options, accommodating diverse application requirements. This versatility makes the YPK107 suitable for everything from simple control tasks to complex process automation.

4. **User-Friendly Interface**: The intuitive interface of the YPK107 simplifies programming and operation, allowing users to quickly adapt to the system. This feature is particularly beneficial for industries that require frequent changes in production setups.

5. **Enhanced Security Features**: With built-in cybersecurity measures, the YPK107 protects critical data and system integrity against potential threats. This is increasingly important in today's interconnected industrial landscape.

6. **Compact Design**: The YPK107’s compact footprint is ideal for installations where space is at a premium, without compromising performance or functionality.

Usage Scenarios

The ABB YPK107 is engineered for a wide array of applications across various industries. Here are some common usage scenarios:

1. **Manufacturing Automation**: In manufacturing plants, the YPK107 can control assembly lines, monitor production processes, and manage robotic systems to enhance efficiency and productivity.

2. **Process Control**: The model is ideal for process industries such as chemical, pharmaceutical, and food processing, where precise control of variables is essential for maintaining quality and compliance with regulatory standards.

3. **Building Automation**: The YPK107 can be utilized in smart building systems for energy management, lighting control, and HVAC optimization, offering significant energy savings and improved occupant comfort.

4. **Logistics and Warehousing**: In logistics, the YPK107 can streamline operations by managing conveyor systems, automated guided vehicles (AGVs), and inventory tracking systems, thus improving throughput and accuracy.

5. **Renewable Energy Systems**: The YPK107 is also applicable in renewable energy systems, such as solar farms and wind energy installations, where it can monitor and control various components for optimal energy generation.

Comparison with Other Models

When comparing the ABB YPK107 with other models in the ABB automation products lineup, several distinctions become apparent. For instance, compared to the ABB TU841, which is renowned for its I/O capabilities, the YPK107 excels with its superior processing speed and flexible communication options.

In contrast to the ABB PM511V16, known for its precision in motion control, the YPK107 offers a broader scope of applications, making it a more versatile choice for manufacturers looking to streamline multiple processes with a single unit. Moreover, while the ABB SDCS-PIN-51 focuses on process control applications, the YPK107 integrates both process and discrete control, making it suitable for a wider variety of industrial scenarios.

Related Models

The ABB YPK107 can be effectively utilized alongside several related models to enhance overall system functionality. Here are ten noteworthy models to consider:

1. **ABB UNS1860B-P**: A reliable option for control systems, complementing the YPK107's capabilities.

2. **ABB PPE100A 3BHE037824R0101**: Excellent for power management applications in conjunction with the YPK107.

3. **ABB TU852 S800 I/O**: An ideal pairing for enhanced I/O flexibility.

4. **ABB YPM106E YT204001-FN**: A versatile model that works well with the YPK107 in various automation scenarios.

5. **ABB PM511V16 3BSE011181R1**: Suitable for motion control applications, can be integrated with the YPK107 for comprehensive automation solutions.

6. **ABB IRB 2600**: A robust industrial robot that can be controlled via the YPK107 for seamless automation in manufacturing processes.

7. **ABB ACS880-01-246A-3**: A drive solution that pairs well with the YPK107 for motor control applications.

8. **ABB DSQC352B**: This model can enhance the YPK107's capabilities in robotic applications.

9. **ABB TB820-1**: A flexible terminal block that complements the YPK107's I/O functionalities.

10. **ABB AGDR-76C**: This model can be used in conjunction with the YPK107 to optimize control in complex automated systems.

In summary, the ABB YPK107 is a powerful and versatile addition to the range of ABB automation products. With its superior processing capabilities, flexible communication protocols, and robust I/O options, it stands ready to tackle a wide variety of applications across different industries. Whether it’s enhancing manufacturing efficiency, optimizing building operations, or streamlining logistics, the YPK107 is engineered to deliver exceptional performance and reliability. Explore the potential of your automation systems with the ABB YPK107 and experience the difference it can make in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

The ABB YPK107 stands out in the extensive portfolio of ABB automation products, designed to optimize performance in various industrial applications. With its robust technical features and innovative design, the YPK107 is engineered to meet the evolving needs of modern automation environments.

Key Technical Features

The ABB YPK107 is distinguished by its advanced performance specifications and versatility. Key features include:

1. **High Processing Speed**: Equipped with a powerful processor, the YPK107 delivers rapid data processing capabilities, enabling real-time decision-making in complex automation systems. This feature ensures minimal latency, which is critical in high-speed manufacturing environments.

2. **Flexible Communication Protocols**: The YPK107 supports multiple communication protocols, including Ethernet/IP, PROFINET, and Modbus. This flexibility allows seamless integration with various devices and systems, enhancing interoperability across different platforms.

3. **Robust I/O Capacity**: The model boasts an extensive range of input/output options, accommodating diverse application requirements. This versatility makes the YPK107 suitable for everything from simple control tasks to complex process automation.

4. **User-Friendly Interface**: The intuitive interface of the YPK107 simplifies programming and operation, allowing users to quickly adapt to the system. This feature is particularly beneficial for industries that require frequent changes in production setups.

5. **Enhanced Security Features**: With built-in cybersecurity measures, the YPK107 protects critical data and system integrity against potential threats. This is increasingly important in today's interconnected industrial landscape.

6. **Compact Design**: The YPK107’s compact footprint is ideal for installations where space is at a premium, without compromising performance or functionality.

Usage Scenarios

The ABB YPK107 is engineered for a wide array of applications across various industries. Here are some common usage scenarios:

1. **Manufacturing Automation**: In manufacturing plants, the YPK107 can control assembly lines, monitor production processes, and manage robotic systems to enhance efficiency and productivity.

2. **Process Control**: The model is ideal for process industries such as chemical, pharmaceutical, and food processing, where precise control of variables is essential for maintaining quality and compliance with regulatory standards.

3. **Building Automation**: The YPK107 can be utilized in smart building systems for energy management, lighting control, and HVAC optimization, offering significant energy savings and improved occupant comfort.

4. **Logistics and Warehousing**: In logistics, the YPK107 can streamline operations by managing conveyor systems, automated guided vehicles (AGVs), and inventory tracking systems, thus improving throughput and accuracy.

5. **Renewable Energy Systems**: The YPK107 is also applicable in renewable energy systems, such as solar farms and wind energy installations, where it can monitor and control various components for optimal energy generation.

Comparison with Other Models

When comparing the ABB YPK107 with other models in the ABB automation products lineup, several distinctions become apparent. For instance, compared to the ABB TU841, which is renowned for its I/O capabilities, the YPK107 excels with its superior processing speed and flexible communication options.

In contrast to the ABB PM511V16, known for its precision in motion control, the YPK107 offers a broader scope of applications, making it a more versatile choice for manufacturers looking to streamline multiple processes with a single unit. Moreover, while the ABB SDCS-PIN-51 focuses on process control applications, the YPK107 integrates both process and discrete control, making it suitable for a wider variety of industrial scenarios.

Related Models

The ABB YPK107 can be effectively utilized alongside several related models to enhance overall system functionality. Here are ten noteworthy models to consider:

1. **ABB UNS1860B-P**: A reliable option for control systems, complementing the YPK107's capabilities.

2. **ABB PPE100A 3BHE037824R0101**: Excellent for power management applications in conjunction with the YPK107.

3. **ABB TU852 S800 I/O**: An ideal pairing for enhanced I/O flexibility.

4. **ABB YPM106E YT204001-FN**: A versatile model that works well with the YPK107 in various automation scenarios.

5. **ABB PM511V16 3BSE011181R1**: Suitable for motion control applications, can be integrated with the YPK107 for comprehensive automation solutions.

6. **ABB IRB 2600**: A robust industrial robot that can be controlled via the YPK107 for seamless automation in manufacturing processes.

7. **ABB ACS880-01-246A-3**: A drive solution that pairs well with the YPK107 for motor control applications.

8. **ABB DSQC352B**: This model can enhance the YPK107's capabilities in robotic applications.

9. **ABB TB820-1**: A flexible terminal block that complements the YPK107's I/O functionalities.

10. **ABB AGDR-76C**: This model can be used in conjunction with the YPK107 to optimize control in complex automated systems.

In summary, the ABB YPK107 is a powerful and versatile addition to the range of ABB automation products. With its superior processing capabilities, flexible communication protocols, and robust I/O options, it stands ready to tackle a wide variety of applications across different industries. Whether it’s enhancing manufacturing efficiency, optimizing building operations, or streamlining logistics, the YPK107 is engineered to deliver exceptional performance and reliability. Explore the potential of your automation systems with the ABB YPK107 and experience the difference it can make in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.