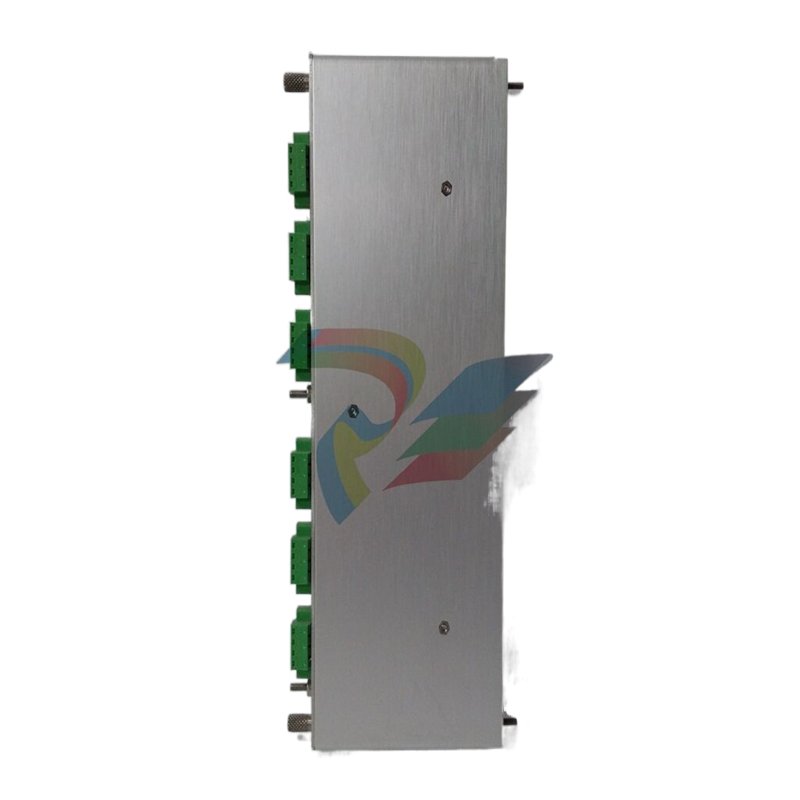

BENTLY 135613-02 High Temperature Case Expansion Transducer Assembly, Precision Measuring Solution

Introducing the BENTLY 135613-02: the pinnacle of advanced monitoring and diagnostic solutions in industrial applications. BENTLY, a trusted name in automation products, continues to push the boundaries of technology with this innovative model, expertly designed to meet the rigorous demands of modern industry.

Key Technical Features

The BENTLY 135613-02 is engineered with a range of cutting-edge features that set it apart from competitors. At its core, the model boasts exceptional data acquisition capabilities, allowing for real-time monitoring of critical parameters. Its high-speed data processing unit ensures accurate analysis, enabling users to make informed decisions quickly.

One of the standout features of the BENTLY 135613-02 is its multi-channel capability, allowing simultaneous monitoring of multiple data points. This versatility is particularly beneficial in complex environments where various machinery and systems operate concurrently. With an impressive sampling rate, users can expect precise readings, enhancing predictive maintenance strategies and minimizing unplanned downtimes.

The model also features robust networking options, including Ethernet and serial communication, ensuring seamless integration with existing systems. This flexibility is crucial for industries looking to upgrade their infrastructure without overhauling their entire setup. With built-in diagnostic tools, the BENTLY 135613-02 provides alerts and notifications that help identify potential issues before they escalate, ensuring operational efficiency and safety.

Usage Scenarios

The BENTLY 135613-02 is ideal for a plethora of industrial applications, including power generation, oil and gas, and manufacturing. In power generation, for instance, it can monitor turbine health, providing vital data on vibration and temperature. This information is essential for maintaining optimal performance and extending the lifespan of critical equipment.

In the oil and gas sector, the BENTLY 135613-02 is invaluable for monitoring pipelines and drilling operations. By providing real-time data, it helps operators identify leaks or anomalies, thereby preventing environmental hazards and costly repairs. Furthermore, in manufacturing, this model can oversee assembly line machinery, ensuring that production remains uninterrupted and efficient.

The BENTLY 135613-02 is also well-suited for facilities that rely heavily on automation. Its compatibility with various BENTLY automation products allows for integrated solutions that enhance overall system performance. Whether monitoring pumps, compressors, or generators, this model provides the reliability and accuracy that industries demand.

Comparison with Other Models

When comparing the BENTLY 135613-02 to other models in the BENTLY lineup, such as the BENTLY 3500/20 125744-02 or the BENTLY 3500/40M, several distinctions become apparent. While the 3500 series is renowned for its extensive data logging capabilities, the 135613-02 excels in real-time monitoring with advanced diagnostic features. This makes the 135613-02 particularly appealing to industries focused on immediate data utilization and proactive maintenance.

In contrast to the BENTLY 3500/50, which is designed for specific applications, the 135613-02 offers a broader range of monitoring capabilities, making it more adaptable across various industries. Additionally, the BENTLY 3500/34 provides excellent vibration monitoring, but the 135613-02's multi-channel design gives it an edge in environments where simultaneous data collection is critical.

Reference to Related Models

For those considering the BENTLY 135613-02, it's worth exploring several related models that complement its features. These include:

1. BENTLY 3500/20 125744-02 – Known for its robust data logging capabilities.

2. BENTLY 131151-01 – A reliable choice for basic monitoring applications.

3. BENTLY 3500/45 176449-04 – Specializes in advanced vibration analysis.

4. BENTLY 3500/42M – Focused on machinery protection with real-time alerts.

5. BENTLY Nevada – A well-regarded line for asset condition monitoring.

6. BENTLY 3500/50 – Offers specialized monitoring for specific applications.

7. BENTLY 3500/92 – A high-performance model for extensive monitoring needs.

8. BENTLY 3500/34 – Ideal for vibration monitoring in rotating equipment.

9. BENTLY 3500/40M – Provides enhanced diagnostics for machinery.

10. BENTLY 3300/20-12-01-03-00-00 – A versatile choice for condition monitoring.

These models, along with the BENTLY 135613-02, create a comprehensive suite of monitoring solutions tailored to various industrial needs. Each model has its strengths, but the 135613-02 stands out for its real-time capabilities and multi-channel functionality.

Conclusion

The BENTLY 135613-02 represents a significant advancement in the field of industrial automation and monitoring. With its superior technical features, versatile usage scenarios, and adaptability in comparison to other models, it is an essential tool for industries aiming to enhance operational efficiency and minimize downtime. Whether you are in power generation, oil and gas, or manufacturing, the BENTLY 135613-02 is designed to meet your needs head-on.

By choosing the BENTLY 135613-02, you are not just investing in a product; you are equipping your operations with a powerful tool that embodies the future of industrial monitoring. With BENTLY automation products, you gain a trusted partner in your journey toward enhanced productivity and safety.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY 135613-02 is engineered with a range of cutting-edge features that set it apart from competitors. At its core, the model boasts exceptional data acquisition capabilities, allowing for real-time monitoring of critical parameters. Its high-speed data processing unit ensures accurate analysis, enabling users to make informed decisions quickly.

One of the standout features of the BENTLY 135613-02 is its multi-channel capability, allowing simultaneous monitoring of multiple data points. This versatility is particularly beneficial in complex environments where various machinery and systems operate concurrently. With an impressive sampling rate, users can expect precise readings, enhancing predictive maintenance strategies and minimizing unplanned downtimes.

The model also features robust networking options, including Ethernet and serial communication, ensuring seamless integration with existing systems. This flexibility is crucial for industries looking to upgrade their infrastructure without overhauling their entire setup. With built-in diagnostic tools, the BENTLY 135613-02 provides alerts and notifications that help identify potential issues before they escalate, ensuring operational efficiency and safety.

Usage Scenarios

The BENTLY 135613-02 is ideal for a plethora of industrial applications, including power generation, oil and gas, and manufacturing. In power generation, for instance, it can monitor turbine health, providing vital data on vibration and temperature. This information is essential for maintaining optimal performance and extending the lifespan of critical equipment.

In the oil and gas sector, the BENTLY 135613-02 is invaluable for monitoring pipelines and drilling operations. By providing real-time data, it helps operators identify leaks or anomalies, thereby preventing environmental hazards and costly repairs. Furthermore, in manufacturing, this model can oversee assembly line machinery, ensuring that production remains uninterrupted and efficient.

The BENTLY 135613-02 is also well-suited for facilities that rely heavily on automation. Its compatibility with various BENTLY automation products allows for integrated solutions that enhance overall system performance. Whether monitoring pumps, compressors, or generators, this model provides the reliability and accuracy that industries demand.

Comparison with Other Models

When comparing the BENTLY 135613-02 to other models in the BENTLY lineup, such as the BENTLY 3500/20 125744-02 or the BENTLY 3500/40M, several distinctions become apparent. While the 3500 series is renowned for its extensive data logging capabilities, the 135613-02 excels in real-time monitoring with advanced diagnostic features. This makes the 135613-02 particularly appealing to industries focused on immediate data utilization and proactive maintenance.

In contrast to the BENTLY 3500/50, which is designed for specific applications, the 135613-02 offers a broader range of monitoring capabilities, making it more adaptable across various industries. Additionally, the BENTLY 3500/34 provides excellent vibration monitoring, but the 135613-02's multi-channel design gives it an edge in environments where simultaneous data collection is critical.

Reference to Related Models

For those considering the BENTLY 135613-02, it's worth exploring several related models that complement its features. These include:

1. BENTLY 3500/20 125744-02 – Known for its robust data logging capabilities.

2. BENTLY 131151-01 – A reliable choice for basic monitoring applications.

3. BENTLY 3500/45 176449-04 – Specializes in advanced vibration analysis.

4. BENTLY 3500/42M – Focused on machinery protection with real-time alerts.

5. BENTLY Nevada – A well-regarded line for asset condition monitoring.

6. BENTLY 3500/50 – Offers specialized monitoring for specific applications.

7. BENTLY 3500/92 – A high-performance model for extensive monitoring needs.

8. BENTLY 3500/34 – Ideal for vibration monitoring in rotating equipment.

9. BENTLY 3500/40M – Provides enhanced diagnostics for machinery.

10. BENTLY 3300/20-12-01-03-00-00 – A versatile choice for condition monitoring.

These models, along with the BENTLY 135613-02, create a comprehensive suite of monitoring solutions tailored to various industrial needs. Each model has its strengths, but the 135613-02 stands out for its real-time capabilities and multi-channel functionality.

Conclusion

The BENTLY 135613-02 represents a significant advancement in the field of industrial automation and monitoring. With its superior technical features, versatile usage scenarios, and adaptability in comparison to other models, it is an essential tool for industries aiming to enhance operational efficiency and minimize downtime. Whether you are in power generation, oil and gas, or manufacturing, the BENTLY 135613-02 is designed to meet your needs head-on.

By choosing the BENTLY 135613-02, you are not just investing in a product; you are equipping your operations with a powerful tool that embodies the future of industrial monitoring. With BENTLY automation products, you gain a trusted partner in your journey toward enhanced productivity and safety.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.