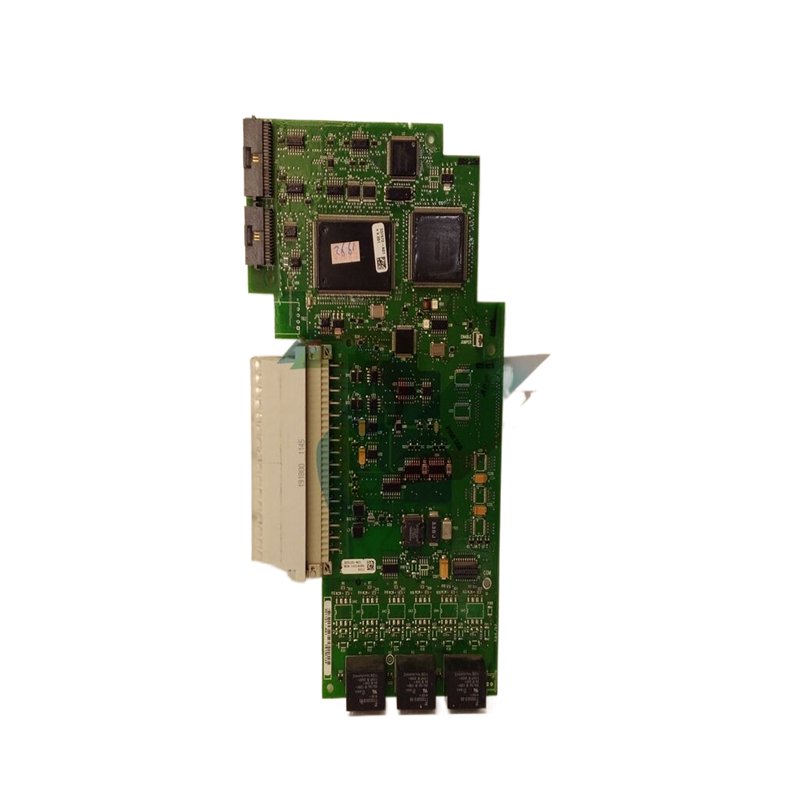

BENTLY 3500/34 Industrial Control Module

Introducing the BENTLY 3500/34: The Pinnacle of Condition Monitoring and Control

In the realm of industrial automation, the BENTLY 3500/34 stands out as a premier solution for condition monitoring and control. Part of the esteemed BENTLY automation products line, this model combines advanced technology with user-friendly features to ensure optimal performance and reliability of critical machinery. Designed for industries where equipment failure can lead to significant downtime and costly repairs, the BENTLY 3500/34 provides unmatched insights into the health of your assets.

Key Technical Features

The BENTLY 3500/34 is engineered with a range of cutting-edge features to deliver precise monitoring and analysis. Key technical specifications include:

– **Comprehensive Vibration Analysis**: The BENTLY 3500/34 utilizes high-fidelity sensors and advanced algorithms to capture detailed vibration data. This capability helps identify potential issues before they escalate into major failures.

– **Multi-Channel Monitoring**: With the ability to monitor up to 8 channels simultaneously, this model supports extensive data collection, allowing for in-depth analysis across multiple machines or components.

– **Integrated Diagnostics**: The BENTLY 3500/34 features real-time diagnostics that provide alerts for abnormal conditions. Users can leverage this information to make informed maintenance decisions and enhance operational efficiency.

– **Flexible Connectivity Options**: The model supports various connectivity options, including Ethernet and serial communication, ensuring seamless integration with existing systems and facilitating data sharing across platforms.

– **User-Friendly Interface**: A straightforward interface allows operators to easily access critical data and system alerts, making it simple to interpret findings and take action.

Usage Scenarios

The versatility of the BENTLY 3500/34 makes it suitable for a multitude of applications across various industries. Common usage scenarios include:

– **Power Generation**: In power plants, the BENTLY 3500/34 is employed to monitor critical rotating equipment such as turbines and generators, ensuring they operate smoothly and efficiently.

– **Oil and Gas**: This model is invaluable in the oil and gas sector for tracking the condition of pumps, compressors, and other machinery, helping to prevent costly outages.

– **Manufacturing**: In manufacturing facilities, the BENTLY 3500/34 monitors equipment like motors and conveyors, providing insights that improve overall production reliability.

– **Water and Wastewater Treatment**: The model is used to monitor pumps and motors in treatment plants, ensuring optimal performance and compliance with regulatory standards.

Comparison with Other Models

When comparing the BENTLY 3500/34 to other models within the BENTLY automation products line, its capabilities shine. For instance, the BENTLY 3500/20 focuses primarily on vibration monitoring but lacks the multi-channel flexibility offered by the 3500/34. On the other hand, the BENTLY 3500/40M provides enhanced monitoring capabilities for machinery but may not deliver the same level of diagnostic insights as the 3500/34.

While the BENTLY 3500/50 is known for its robust performance in high-speed applications, the 3500/34 provides a balanced approach with its versatile monitoring options, making it ideal for a broader range of industrial contexts. Additionally, the BENTLY 3500/42M and 3500/53 cater to specific niche requirements, yet the 3500/34 remains the go-to for comprehensive condition monitoring across diverse applications.

Related Models

The BENTLY 3500/34 is part of a broad portfolio of related models that cater to various monitoring and automation needs. Here are ten models that complement the capabilities of the 3500/34:

1. BENTLY 3500/20 125744-02 – Focused on vibration monitoring.

2. BENTLY 3500/45 176449-04 – Designed for advanced machinery protection.

3. BENTLY 330500-00-00 – A versatile monitoring solution for different applications.

4. BENTLY 3500/40M – Known for its high-speed monitoring capabilities.

5. BENTLY 3500/42M – Offers enhanced monitoring for specific machinery.

6. BENTLY 3500/50 – Ideal for high-performance applications.

7. BENTLY 3500/92 – Focused on advanced machinery diagnostics.

8. BENTLY 3500/25 – A model tailored for simpler monitoring tasks.

9. BENTLY 3500/53 – Known for its robust data collection features.

10. BENTLY 3500/15 – A reliable model for basic vibration monitoring.

Why Choose the BENTLY 3500/34?

Choosing the BENTLY 3500/34 means investing in a future-proof solution that enhances the reliability and efficiency of your industrial operations. With its comprehensive features and user-friendly design, this model stands as a testament to BENTLY's commitment to quality and innovation in automation products.

The integration of advanced technology with practical functionality makes the BENTLY 3500/34 an essential tool for organizations seeking to minimize downtime and maximize asset performance. Its ability to provide real-time insights and diagnostics empowers operators to make proactive decisions, ensuring machinery operates at peak performance levels.

In conclusion, the BENTLY 3500/34 is not just another condition monitoring device; it is a powerful ally in your quest for operational excellence. Whether you are in power generation, oil and gas, manufacturing, or wastewater treatment, the BENTLY 3500/34 delivers the reliability and precision you need to keep your operations running smoothly. Explore the world of BENTLY automation products today and discover how the 3500/34 can transform your maintenance strategies and equipment performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the realm of industrial automation, the BENTLY 3500/34 stands out as a premier solution for condition monitoring and control. Part of the esteemed BENTLY automation products line, this model combines advanced technology with user-friendly features to ensure optimal performance and reliability of critical machinery. Designed for industries where equipment failure can lead to significant downtime and costly repairs, the BENTLY 3500/34 provides unmatched insights into the health of your assets.

Key Technical Features

The BENTLY 3500/34 is engineered with a range of cutting-edge features to deliver precise monitoring and analysis. Key technical specifications include:

– **Comprehensive Vibration Analysis**: The BENTLY 3500/34 utilizes high-fidelity sensors and advanced algorithms to capture detailed vibration data. This capability helps identify potential issues before they escalate into major failures.

– **Multi-Channel Monitoring**: With the ability to monitor up to 8 channels simultaneously, this model supports extensive data collection, allowing for in-depth analysis across multiple machines or components.

– **Integrated Diagnostics**: The BENTLY 3500/34 features real-time diagnostics that provide alerts for abnormal conditions. Users can leverage this information to make informed maintenance decisions and enhance operational efficiency.

– **Flexible Connectivity Options**: The model supports various connectivity options, including Ethernet and serial communication, ensuring seamless integration with existing systems and facilitating data sharing across platforms.

– **User-Friendly Interface**: A straightforward interface allows operators to easily access critical data and system alerts, making it simple to interpret findings and take action.

Usage Scenarios

The versatility of the BENTLY 3500/34 makes it suitable for a multitude of applications across various industries. Common usage scenarios include:

– **Power Generation**: In power plants, the BENTLY 3500/34 is employed to monitor critical rotating equipment such as turbines and generators, ensuring they operate smoothly and efficiently.

– **Oil and Gas**: This model is invaluable in the oil and gas sector for tracking the condition of pumps, compressors, and other machinery, helping to prevent costly outages.

– **Manufacturing**: In manufacturing facilities, the BENTLY 3500/34 monitors equipment like motors and conveyors, providing insights that improve overall production reliability.

– **Water and Wastewater Treatment**: The model is used to monitor pumps and motors in treatment plants, ensuring optimal performance and compliance with regulatory standards.

Comparison with Other Models

When comparing the BENTLY 3500/34 to other models within the BENTLY automation products line, its capabilities shine. For instance, the BENTLY 3500/20 focuses primarily on vibration monitoring but lacks the multi-channel flexibility offered by the 3500/34. On the other hand, the BENTLY 3500/40M provides enhanced monitoring capabilities for machinery but may not deliver the same level of diagnostic insights as the 3500/34.

While the BENTLY 3500/50 is known for its robust performance in high-speed applications, the 3500/34 provides a balanced approach with its versatile monitoring options, making it ideal for a broader range of industrial contexts. Additionally, the BENTLY 3500/42M and 3500/53 cater to specific niche requirements, yet the 3500/34 remains the go-to for comprehensive condition monitoring across diverse applications.

Related Models

The BENTLY 3500/34 is part of a broad portfolio of related models that cater to various monitoring and automation needs. Here are ten models that complement the capabilities of the 3500/34:

1. BENTLY 3500/20 125744-02 – Focused on vibration monitoring.

2. BENTLY 3500/45 176449-04 – Designed for advanced machinery protection.

3. BENTLY 330500-00-00 – A versatile monitoring solution for different applications.

4. BENTLY 3500/40M – Known for its high-speed monitoring capabilities.

5. BENTLY 3500/42M – Offers enhanced monitoring for specific machinery.

6. BENTLY 3500/50 – Ideal for high-performance applications.

7. BENTLY 3500/92 – Focused on advanced machinery diagnostics.

8. BENTLY 3500/25 – A model tailored for simpler monitoring tasks.

9. BENTLY 3500/53 – Known for its robust data collection features.

10. BENTLY 3500/15 – A reliable model for basic vibration monitoring.

Why Choose the BENTLY 3500/34?

Choosing the BENTLY 3500/34 means investing in a future-proof solution that enhances the reliability and efficiency of your industrial operations. With its comprehensive features and user-friendly design, this model stands as a testament to BENTLY's commitment to quality and innovation in automation products.

The integration of advanced technology with practical functionality makes the BENTLY 3500/34 an essential tool for organizations seeking to minimize downtime and maximize asset performance. Its ability to provide real-time insights and diagnostics empowers operators to make proactive decisions, ensuring machinery operates at peak performance levels.

In conclusion, the BENTLY 3500/34 is not just another condition monitoring device; it is a powerful ally in your quest for operational excellence. Whether you are in power generation, oil and gas, manufacturing, or wastewater treatment, the BENTLY 3500/34 delivers the reliability and precision you need to keep your operations running smoothly. Explore the world of BENTLY automation products today and discover how the 3500/34 can transform your maintenance strategies and equipment performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.