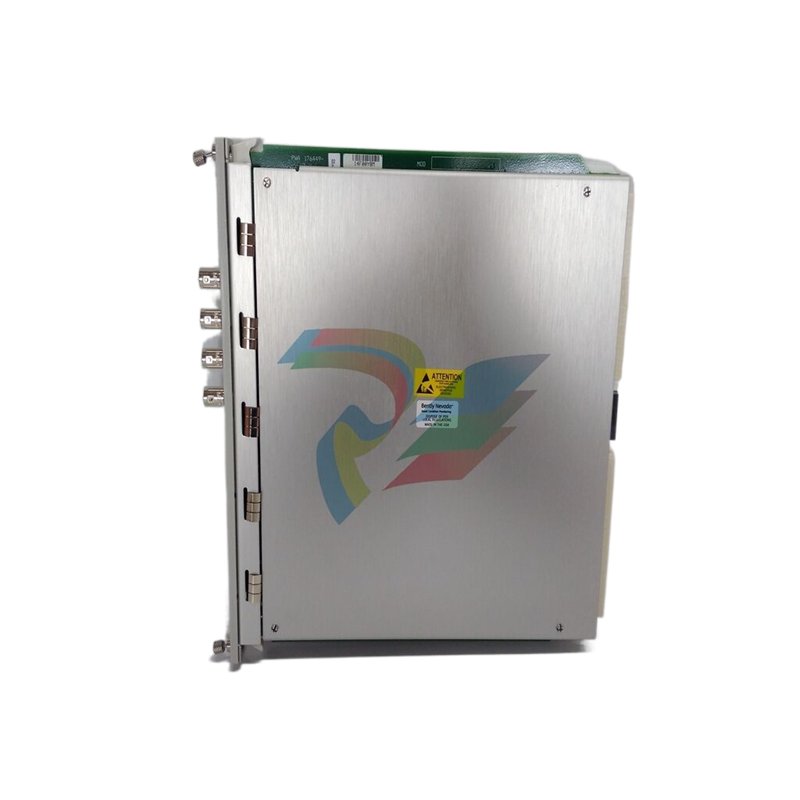

BENTLY 3500/50 133388-02 Control Module

Introducing the BENTLY 3500/50 – the pinnacle of reliability and precision in condition monitoring systems. Designed to enhance the performance and longevity of your industrial machinery, the BENTLY 3500/50 offers a sophisticated solution for real-time data acquisition and analysis. With its robust architecture and advanced features, this model stands out in the BENTLY automation products lineup, making it an essential tool for any maintenance and engineering professional.

Key Technical Features

The BENTLY 3500/50 is equipped with a variety of high-performance features that ensure optimal monitoring of critical machinery components. This model specializes in vibration monitoring and is designed to provide real-time data on the health of rotating machinery.

1. **Advanced Vibration Analysis**: The BENTLY 3500/50 utilizes advanced algorithms to analyze vibration signals, allowing for early detection of potential faults. This ensures timely intervention and prevents costly downtime.

2. **Flexible Configuration Options**: The system supports multiple configurations, enabling users to tailor the setup to specific application needs. It can monitor up to four channels of vibration data, providing comprehensive insights into machine health.

3. **User-Friendly Interface**: The BENTLY 3500/50 features an intuitive interface that simplifies the monitoring process. Users can easily navigate through data displays and settings, making it accessible even for those with limited technical expertise.

4. **Integration Capabilities**: This model seamlessly integrates with the BENTLY 3500 series, allowing for expanded monitoring capabilities. It can be combined with other BENTLY products, such as the 3500/20 and 3500/40M, to create a comprehensive condition monitoring system.

5. **Durability and Reliability**: Built to withstand harsh industrial environments, the BENTLY 3500/50 is designed with rugged components and protective enclosures, ensuring reliable performance in challenging conditions.

Usage Scenarios

The BENTLY 3500/50 is ideal for various industries and applications where machinery health is critical. Here are some common usage scenarios:

1. **Power Generation**: In power plants, the BENTLY 3500/50 monitors turbines and generators to prevent failures that can lead to costly outages.

2. **Oil and Gas**: For oil and gas operations, this model tracks the health of pumps, compressors, and other critical machinery, ensuring efficient and safe production processes.

3. **Manufacturing**: In manufacturing facilities, the BENTLY 3500/50 helps maintain the performance of conveyor systems, motors, and other rotating equipment, thus minimizing unplanned downtime.

4. **Mining**: The rugged design of the BENTLY 3500/50 makes it perfect for monitoring heavy machinery in mining applications, where reliability is paramount.

5. **Water and Wastewater Treatment**: This model ensures the operational efficiency of pumps and blowers in treatment facilities, contributing to sustainable water management.

Comparison with Other Models

When comparing the BENTLY 3500/50 with other models in the BENTLY automation products series, several distinctions become evident.

– **BENTLY 3500/20**: While the 3500/20 focuses on general vibration monitoring, the 3500/50 offers enhanced analytical capabilities, making it more suitable for complex machinery.

– **BENTLY 3500/40M**: The 3500/40M is designed for temperature monitoring, whereas the 3500/50 prioritizes vibration analysis, making it the better choice for applications where vibration data is critical.

– **BENTLY 3500/53**: Although the 3500/53 offers similar features, the 3500/50 is particularly advantageous for users seeking a dedicated vibration monitoring solution.

– **BENTLY 3500/92**: The 3500/92 provides additional capabilities for machinery protection; however, the 3500/50 is optimized for real-time vibration analysis, which is essential for predictive maintenance strategies.

– **BENTLY Nevada**: The BENTLY Nevada series focuses on broader condition monitoring solutions, while the 3500/50 specializes in vibration, making it a more targeted option for users needing specific vibration insights.

Related Models

The BENTLY 3500/50 is part of a comprehensive lineup of condition monitoring products, and it’s essential to consider related models to create a complete monitoring solution:

1. **BENTLY 3500/20 125744-02**: General vibration monitoring.

2. **BENTLY 3500/40M**: Temperature monitoring.

3. **BENTLY 3500/45 176449-04**: Machine protection and monitoring.

4. **BENTLY 3500/34**: Advanced monitoring for other critical parameters.

5. **BENTLY 3500/42M**: Multi-channel monitoring capabilities.

6. **BENTLY 3500/53**: Enhanced vibration monitoring.

7. **BENTLY 3500/25**: Focused on specific machinery types.

8. **BENTLY 3500/15**: Compact monitoring solution.

9. **BENTLY 3300/16-11-01-03-00-00-01**: Portable vibration monitoring.

10. **BENTLY 3500/93 P/N:135785-02**: Comprehensive condition monitoring.

In conclusion, the BENTLY 3500/50 is an exceptional choice for professionals seeking an advanced vibration monitoring solution. With its robust technical features, versatile usage scenarios, and clear advantages over other models, it is the ideal tool to enhance machinery performance and reliability. As part of the BENTLY automation products range, the 3500/50 stands out as a crucial investment for optimizing operational efficiency and ensuring the longevity of your critical equipment. Consider integrating the BENTLY 3500/50 into your monitoring strategy and experience the difference in reliability and performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY 3500/50 is equipped with a variety of high-performance features that ensure optimal monitoring of critical machinery components. This model specializes in vibration monitoring and is designed to provide real-time data on the health of rotating machinery.

1. **Advanced Vibration Analysis**: The BENTLY 3500/50 utilizes advanced algorithms to analyze vibration signals, allowing for early detection of potential faults. This ensures timely intervention and prevents costly downtime.

2. **Flexible Configuration Options**: The system supports multiple configurations, enabling users to tailor the setup to specific application needs. It can monitor up to four channels of vibration data, providing comprehensive insights into machine health.

3. **User-Friendly Interface**: The BENTLY 3500/50 features an intuitive interface that simplifies the monitoring process. Users can easily navigate through data displays and settings, making it accessible even for those with limited technical expertise.

4. **Integration Capabilities**: This model seamlessly integrates with the BENTLY 3500 series, allowing for expanded monitoring capabilities. It can be combined with other BENTLY products, such as the 3500/20 and 3500/40M, to create a comprehensive condition monitoring system.

5. **Durability and Reliability**: Built to withstand harsh industrial environments, the BENTLY 3500/50 is designed with rugged components and protective enclosures, ensuring reliable performance in challenging conditions.

Usage Scenarios

The BENTLY 3500/50 is ideal for various industries and applications where machinery health is critical. Here are some common usage scenarios:

1. **Power Generation**: In power plants, the BENTLY 3500/50 monitors turbines and generators to prevent failures that can lead to costly outages.

2. **Oil and Gas**: For oil and gas operations, this model tracks the health of pumps, compressors, and other critical machinery, ensuring efficient and safe production processes.

3. **Manufacturing**: In manufacturing facilities, the BENTLY 3500/50 helps maintain the performance of conveyor systems, motors, and other rotating equipment, thus minimizing unplanned downtime.

4. **Mining**: The rugged design of the BENTLY 3500/50 makes it perfect for monitoring heavy machinery in mining applications, where reliability is paramount.

5. **Water and Wastewater Treatment**: This model ensures the operational efficiency of pumps and blowers in treatment facilities, contributing to sustainable water management.

Comparison with Other Models

When comparing the BENTLY 3500/50 with other models in the BENTLY automation products series, several distinctions become evident.

– **BENTLY 3500/20**: While the 3500/20 focuses on general vibration monitoring, the 3500/50 offers enhanced analytical capabilities, making it more suitable for complex machinery.

– **BENTLY 3500/40M**: The 3500/40M is designed for temperature monitoring, whereas the 3500/50 prioritizes vibration analysis, making it the better choice for applications where vibration data is critical.

– **BENTLY 3500/53**: Although the 3500/53 offers similar features, the 3500/50 is particularly advantageous for users seeking a dedicated vibration monitoring solution.

– **BENTLY 3500/92**: The 3500/92 provides additional capabilities for machinery protection; however, the 3500/50 is optimized for real-time vibration analysis, which is essential for predictive maintenance strategies.

– **BENTLY Nevada**: The BENTLY Nevada series focuses on broader condition monitoring solutions, while the 3500/50 specializes in vibration, making it a more targeted option for users needing specific vibration insights.

Related Models

The BENTLY 3500/50 is part of a comprehensive lineup of condition monitoring products, and it’s essential to consider related models to create a complete monitoring solution:

1. **BENTLY 3500/20 125744-02**: General vibration monitoring.

2. **BENTLY 3500/40M**: Temperature monitoring.

3. **BENTLY 3500/45 176449-04**: Machine protection and monitoring.

4. **BENTLY 3500/34**: Advanced monitoring for other critical parameters.

5. **BENTLY 3500/42M**: Multi-channel monitoring capabilities.

6. **BENTLY 3500/53**: Enhanced vibration monitoring.

7. **BENTLY 3500/25**: Focused on specific machinery types.

8. **BENTLY 3500/15**: Compact monitoring solution.

9. **BENTLY 3300/16-11-01-03-00-00-01**: Portable vibration monitoring.

10. **BENTLY 3500/93 P/N:135785-02**: Comprehensive condition monitoring.

In conclusion, the BENTLY 3500/50 is an exceptional choice for professionals seeking an advanced vibration monitoring solution. With its robust technical features, versatile usage scenarios, and clear advantages over other models, it is the ideal tool to enhance machinery performance and reliability. As part of the BENTLY automation products range, the 3500/50 stands out as a crucial investment for optimizing operational efficiency and ensuring the longevity of your critical equipment. Consider integrating the BENTLY 3500/50 into your monitoring strategy and experience the difference in reliability and performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.