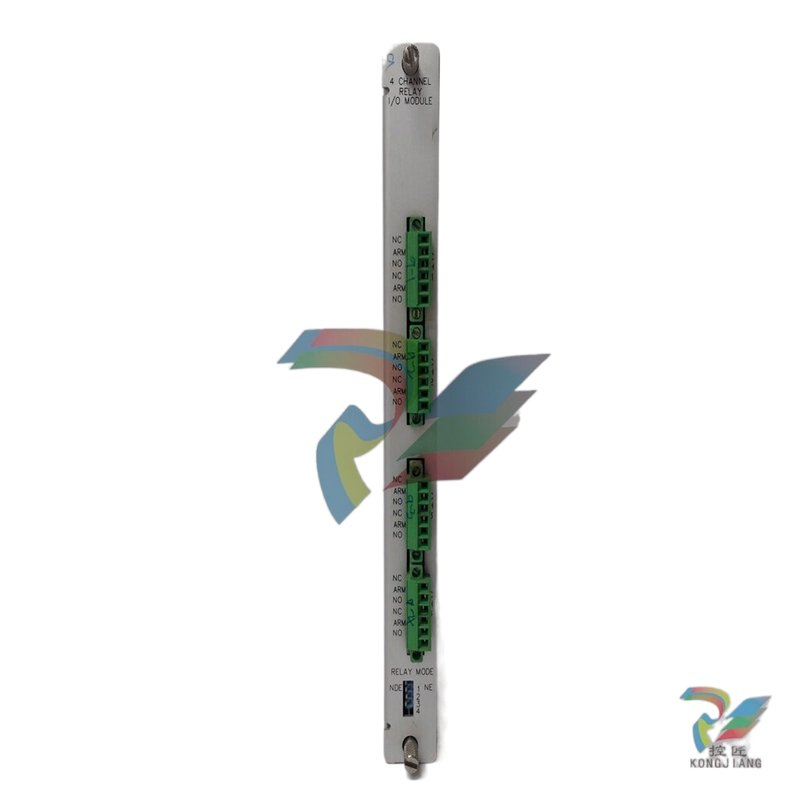

BENTLY Nevada 138708-01 Advanced PLC Module for Industrial Automation

Introducing the BENTLY Nevada 138708-01, a cutting-edge solution in the realm of industrial automation and monitoring. Engineered for reliability and precision, this model exemplifies BENTLY’s commitment to excellence in performance and functionality. The BENTLY Nevada 138708-01 is designed to optimize asset management and enhance operational efficiency, making it an essential component for industries such as oil and gas, power generation, and manufacturing.

Key Technical Features:

The BENTLY Nevada 138708-01 boasts a range of advanced technical features that set it apart from the competition. At the heart of its design is its high-resolution data acquisition capability, enabling real-time monitoring of machinery health. This model supports a wide array of sensors, allowing for comprehensive vibration analysis, temperature monitoring, and other critical measurements. With its robust communication interface, the BENTLY Nevada 138708-01 seamlessly integrates into existing control systems, enhancing data accessibility and operational insight.

One of the standout features of the BENTLY Nevada 138708-01 is its exceptional data processing power. With built-in algorithms for fault detection, it can identify potential issues before they escalate into costly failures. Additionally, the device supports advanced diagnostics and trend analysis, providing users with actionable insights that drive maintenance decisions. The user-friendly interface and intuitive software further simplify operation and monitoring, ensuring that teams can focus on optimizing performance rather than troubleshooting complex systems.

Usage Scenarios:

The BENTLY Nevada 138708-01 is versatile and well-suited for various usage scenarios across multiple industries. In the oil and gas sector, for instance, it can be employed to monitor rotating equipment, such as pumps and compressors, ensuring they operate within safe parameters. By providing early warnings of potential malfunctions, it minimizes downtime and enhances safety.

In power generation, the BENTLY Nevada 138708-01 plays a crucial role in monitoring turbines and generators. Its ability to analyze vibrations and thermal conditions helps operators maintain peak performance while reducing the risk of unexpected outages. Manufacturing facilities also benefit from its capabilities, using it for condition monitoring on critical machinery to ensure smooth operations and high productivity.

Comparison with Other Models:

When comparing the BENTLY Nevada 138708-01 to other models within the BENTLY automation products lineup, it stands out for its advanced diagnostic capabilities and user-friendly design. For instance, the BENTLY 3500/20 (125744-02) offers robust monitoring solutions for machinery, but may lack some of the advanced processing algorithms found in the 138708-01. Similarly, while the BENTLY 3500/50 is known for its reliability, it does not provide the same level of detailed analytics that the Nevada 138708-01 offers.

In contrast to models like the BENTLY 3500/40M or BENTLY 3500/92, which are designed for specific applications, the Nevada 138708-01 delivers a more comprehensive solution adaptable to various environments. This flexibility makes it a preferred choice for organizations looking to streamline their monitoring processes without compromising on performance.

Related Models:

For those exploring options within the BENTLY product family, several models complement the functionality of the BENTLY Nevada 138708-01. The BENTLY 131151-01 is another reliable model focused on vibration monitoring, while the BENTLY 3500/34 and BENTLY 3500/45 are also worth considering for their versatile applications in industrial settings.

The BENTLY 3500/42M offers enhanced monitoring for rotating equipment, and the BENTLY 3500/25 is ideal for condition-based monitoring scenarios. For those needing more specialized solutions, models like the BENTLY 3300/20-12-01-03-00-00 and BENTLY 3500/72M provide additional capabilities tailored to specific machinery types.

Choosing the right model depends on individual operational needs, and understanding the nuances between these models can help users make informed decisions that best suit their requirements.

Conclusion:

The BENTLY Nevada 138708-01 represents the pinnacle of industrial automation solutions, combining advanced technology with user-centric design. Its ability to provide real-time monitoring, data analytics, and seamless integration makes it an indispensable asset for industries aiming to enhance operational efficiency and minimize downtime. With a range of related models to choose from, users can tailor their monitoring solutions to meet specific application needs, ensuring the highest level of performance for their critical machinery.

Investing in the BENTLY Nevada 138708-01 is a decision that not only safeguards assets but also empowers organizations to navigate the complexities of modern industrial environments with confidence and precision. Experience the unparalleled capabilities of this model and discover how it can transform your operations today.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY Nevada 138708-01 boasts a range of advanced technical features that set it apart from the competition. At the heart of its design is its high-resolution data acquisition capability, enabling real-time monitoring of machinery health. This model supports a wide array of sensors, allowing for comprehensive vibration analysis, temperature monitoring, and other critical measurements. With its robust communication interface, the BENTLY Nevada 138708-01 seamlessly integrates into existing control systems, enhancing data accessibility and operational insight.

One of the standout features of the BENTLY Nevada 138708-01 is its exceptional data processing power. With built-in algorithms for fault detection, it can identify potential issues before they escalate into costly failures. Additionally, the device supports advanced diagnostics and trend analysis, providing users with actionable insights that drive maintenance decisions. The user-friendly interface and intuitive software further simplify operation and monitoring, ensuring that teams can focus on optimizing performance rather than troubleshooting complex systems.

Usage Scenarios:

The BENTLY Nevada 138708-01 is versatile and well-suited for various usage scenarios across multiple industries. In the oil and gas sector, for instance, it can be employed to monitor rotating equipment, such as pumps and compressors, ensuring they operate within safe parameters. By providing early warnings of potential malfunctions, it minimizes downtime and enhances safety.

In power generation, the BENTLY Nevada 138708-01 plays a crucial role in monitoring turbines and generators. Its ability to analyze vibrations and thermal conditions helps operators maintain peak performance while reducing the risk of unexpected outages. Manufacturing facilities also benefit from its capabilities, using it for condition monitoring on critical machinery to ensure smooth operations and high productivity.

Comparison with Other Models:

When comparing the BENTLY Nevada 138708-01 to other models within the BENTLY automation products lineup, it stands out for its advanced diagnostic capabilities and user-friendly design. For instance, the BENTLY 3500/20 (125744-02) offers robust monitoring solutions for machinery, but may lack some of the advanced processing algorithms found in the 138708-01. Similarly, while the BENTLY 3500/50 is known for its reliability, it does not provide the same level of detailed analytics that the Nevada 138708-01 offers.

In contrast to models like the BENTLY 3500/40M or BENTLY 3500/92, which are designed for specific applications, the Nevada 138708-01 delivers a more comprehensive solution adaptable to various environments. This flexibility makes it a preferred choice for organizations looking to streamline their monitoring processes without compromising on performance.

Related Models:

For those exploring options within the BENTLY product family, several models complement the functionality of the BENTLY Nevada 138708-01. The BENTLY 131151-01 is another reliable model focused on vibration monitoring, while the BENTLY 3500/34 and BENTLY 3500/45 are also worth considering for their versatile applications in industrial settings.

The BENTLY 3500/42M offers enhanced monitoring for rotating equipment, and the BENTLY 3500/25 is ideal for condition-based monitoring scenarios. For those needing more specialized solutions, models like the BENTLY 3300/20-12-01-03-00-00 and BENTLY 3500/72M provide additional capabilities tailored to specific machinery types.

Choosing the right model depends on individual operational needs, and understanding the nuances between these models can help users make informed decisions that best suit their requirements.

Conclusion:

The BENTLY Nevada 138708-01 represents the pinnacle of industrial automation solutions, combining advanced technology with user-centric design. Its ability to provide real-time monitoring, data analytics, and seamless integration makes it an indispensable asset for industries aiming to enhance operational efficiency and minimize downtime. With a range of related models to choose from, users can tailor their monitoring solutions to meet specific application needs, ensuring the highest level of performance for their critical machinery.

Investing in the BENTLY Nevada 138708-01 is a decision that not only safeguards assets but also empowers organizations to navigate the complexities of modern industrial environments with confidence and precision. Experience the unparalleled capabilities of this model and discover how it can transform your operations today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.