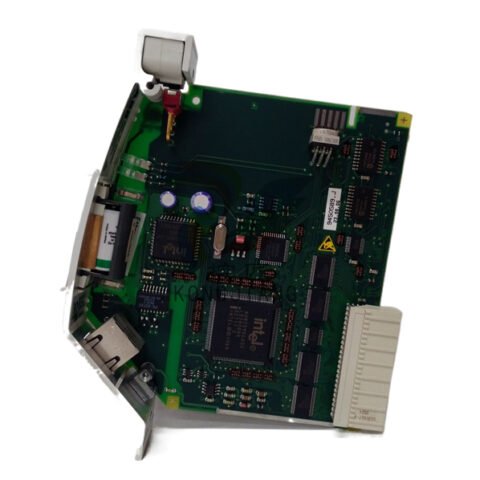

BENTLY Nevada 1900/65A-01-01-01-00-01 General Purpose Equipment Monitor

Introducing the BENTLY Nevada: The Ultimate Solution for Condition Monitoring and Machinery Protection

In the world of industrial automation, the BENTLY Nevada series stands out as a symbol of reliability and precision. This state-of-the-art machinery protection and condition monitoring system is designed to enhance the performance and longevity of critical assets in various sectors, including oil and gas, power generation, manufacturing, and more. The BENTLY Nevada not only meets but exceeds industry standards, making it a preferred choice among professionals seeking robust solutions for their operations.

Key Technical Features

The BENTLY Nevada system is packed with advanced features that set it apart from its competitors. One of its standout features is the unparalleled data acquisition capabilities. With high-speed sampling rates and a wide range of sensor compatibility, the BENTLY Nevada can collect real-time data on vibration, temperature, and other critical parameters. This enables users to perform comprehensive condition monitoring, ensuring that any potential issues are detected early.

Another significant advantage of the BENTLY Nevada is its modular architecture. This design allows for easy integration with existing systems, making it a versatile option for upgrading or expanding your current monitoring capabilities. The system supports various communication protocols, including Ethernet, Modbus, and Profibus, ensuring seamless connectivity with other automation products.

The BENTLY Nevada also boasts advanced diagnostic features that leverage sophisticated algorithms to analyze data trends and provide actionable insights. This predictive maintenance capability helps organizations minimize downtime and optimize maintenance schedules, leading to substantial cost savings over time.

Usage Scenarios

The BENTLY Nevada is ideal for a wide range of applications. In the oil and gas industry, for example, it plays a crucial role in monitoring rotating equipment such as compressors, pumps, and turbines. By providing real-time insights into machinery health, operators can ensure optimal performance and prevent costly failures.

In the power generation sector, the BENTLY Nevada is essential for monitoring generator bearings and steam turbines. Its ability to detect anomalies early allows for timely interventions, ensuring that plants operate efficiently and safely.

Moreover, the BENTLY Nevada is also well-suited for manufacturing environments where precision and uptime are critical. Whether it’s monitoring conveyor systems or critical assembly machinery, the system provides the insights needed to keep production lines running smoothly.

Comparison with Other Models

When comparing the BENTLY Nevada to other models in the BENTLY lineup, such as the BENTLY 3500 series and the BENTLY 3300 series, it becomes evident that the Nevada offers superior data acquisition and diagnostic capabilities. While the BENTLY 3500 series focuses on comprehensive machinery protection, the Nevada enhances condition monitoring with its advanced analytics features.

For instance, the BENTLY 3500/20 provides robust vibration monitoring, but it lacks the extensive data analytics capabilities found in the BENTLY Nevada. Similarly, the BENTLY 3300/20 series is excellent for basic monitoring, but it does not offer the same level of integration and modularity as the Nevada.

In contrast to models like the BENTLY 3500/40M, which is known for its reliability in harsh environments, the BENTLY Nevada takes it a step further by providing enhanced diagnostic tools that can predict failures before they occur. This proactive approach to maintenance sets the Nevada apart from its peers.

Related Models

The BENTLY Nevada is part of an extensive family of automation products, each designed for specific applications. Here are ten related models that complement the BENTLY Nevada:

1. BENTLY 3500/20 125744-02: A reliable vibration monitoring system known for its robustness.

2. BENTLY 3500/45 176449-04: Specifically designed for monitoring gearboxes and rotating equipment.

3. BENTLY 3500/34: Offers comprehensive machinery protection with a focus on critical asset management.

4. BENTLY 132419-01: A versatile model that supports a wide range of industrial applications.

5. BENTLY 3500/50: Known for its high-speed data acquisition capabilities, perfect for demanding environments.

6. BENTLY 330500-00-00: A reliable option for high-frequency applications.

7. BENTLY 3500/92: Features advanced diagnostics for enhanced condition monitoring.

8. BENTLY 3500/25: A compact solution for monitoring a variety of machinery types.

9. BENTLY 3500/53: Integrates seamlessly with existing automation systems for enhanced performance.

10. BENTLY 3500/64M: Designed for multi-channel applications, providing comprehensive monitoring capabilities.

Why Choose BENTLY Nevada?

Choosing the BENTLY Nevada means investing in a future-proof solution that not only meets today’s demands but also adapts to the evolving landscape of industrial automation. With its advanced features, modular design, and unmatched reliability, the BENTLY Nevada stands as a leader in condition monitoring and machinery protection.

In conclusion, if you seek a solution that offers exceptional performance and reliability, look no further than the BENTLY Nevada. Its ability to provide real-time insights and predictive analytics makes it an indispensable tool for any industrial operation. Elevate your condition monitoring capabilities with BENTLY automation products and experience the difference in efficiency and reliability.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the world of industrial automation, the BENTLY Nevada series stands out as a symbol of reliability and precision. This state-of-the-art machinery protection and condition monitoring system is designed to enhance the performance and longevity of critical assets in various sectors, including oil and gas, power generation, manufacturing, and more. The BENTLY Nevada not only meets but exceeds industry standards, making it a preferred choice among professionals seeking robust solutions for their operations.

Key Technical Features

The BENTLY Nevada system is packed with advanced features that set it apart from its competitors. One of its standout features is the unparalleled data acquisition capabilities. With high-speed sampling rates and a wide range of sensor compatibility, the BENTLY Nevada can collect real-time data on vibration, temperature, and other critical parameters. This enables users to perform comprehensive condition monitoring, ensuring that any potential issues are detected early.

Another significant advantage of the BENTLY Nevada is its modular architecture. This design allows for easy integration with existing systems, making it a versatile option for upgrading or expanding your current monitoring capabilities. The system supports various communication protocols, including Ethernet, Modbus, and Profibus, ensuring seamless connectivity with other automation products.

The BENTLY Nevada also boasts advanced diagnostic features that leverage sophisticated algorithms to analyze data trends and provide actionable insights. This predictive maintenance capability helps organizations minimize downtime and optimize maintenance schedules, leading to substantial cost savings over time.

Usage Scenarios

The BENTLY Nevada is ideal for a wide range of applications. In the oil and gas industry, for example, it plays a crucial role in monitoring rotating equipment such as compressors, pumps, and turbines. By providing real-time insights into machinery health, operators can ensure optimal performance and prevent costly failures.

In the power generation sector, the BENTLY Nevada is essential for monitoring generator bearings and steam turbines. Its ability to detect anomalies early allows for timely interventions, ensuring that plants operate efficiently and safely.

Moreover, the BENTLY Nevada is also well-suited for manufacturing environments where precision and uptime are critical. Whether it’s monitoring conveyor systems or critical assembly machinery, the system provides the insights needed to keep production lines running smoothly.

Comparison with Other Models

When comparing the BENTLY Nevada to other models in the BENTLY lineup, such as the BENTLY 3500 series and the BENTLY 3300 series, it becomes evident that the Nevada offers superior data acquisition and diagnostic capabilities. While the BENTLY 3500 series focuses on comprehensive machinery protection, the Nevada enhances condition monitoring with its advanced analytics features.

For instance, the BENTLY 3500/20 provides robust vibration monitoring, but it lacks the extensive data analytics capabilities found in the BENTLY Nevada. Similarly, the BENTLY 3300/20 series is excellent for basic monitoring, but it does not offer the same level of integration and modularity as the Nevada.

In contrast to models like the BENTLY 3500/40M, which is known for its reliability in harsh environments, the BENTLY Nevada takes it a step further by providing enhanced diagnostic tools that can predict failures before they occur. This proactive approach to maintenance sets the Nevada apart from its peers.

Related Models

The BENTLY Nevada is part of an extensive family of automation products, each designed for specific applications. Here are ten related models that complement the BENTLY Nevada:

1. BENTLY 3500/20 125744-02: A reliable vibration monitoring system known for its robustness.

2. BENTLY 3500/45 176449-04: Specifically designed for monitoring gearboxes and rotating equipment.

3. BENTLY 3500/34: Offers comprehensive machinery protection with a focus on critical asset management.

4. BENTLY 132419-01: A versatile model that supports a wide range of industrial applications.

5. BENTLY 3500/50: Known for its high-speed data acquisition capabilities, perfect for demanding environments.

6. BENTLY 330500-00-00: A reliable option for high-frequency applications.

7. BENTLY 3500/92: Features advanced diagnostics for enhanced condition monitoring.

8. BENTLY 3500/25: A compact solution for monitoring a variety of machinery types.

9. BENTLY 3500/53: Integrates seamlessly with existing automation systems for enhanced performance.

10. BENTLY 3500/64M: Designed for multi-channel applications, providing comprehensive monitoring capabilities.

Why Choose BENTLY Nevada?

Choosing the BENTLY Nevada means investing in a future-proof solution that not only meets today’s demands but also adapts to the evolving landscape of industrial automation. With its advanced features, modular design, and unmatched reliability, the BENTLY Nevada stands as a leader in condition monitoring and machinery protection.

In conclusion, if you seek a solution that offers exceptional performance and reliability, look no further than the BENTLY Nevada. Its ability to provide real-time insights and predictive analytics makes it an indispensable tool for any industrial operation. Elevate your condition monitoring capabilities with BENTLY automation products and experience the difference in efficiency and reliability.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.