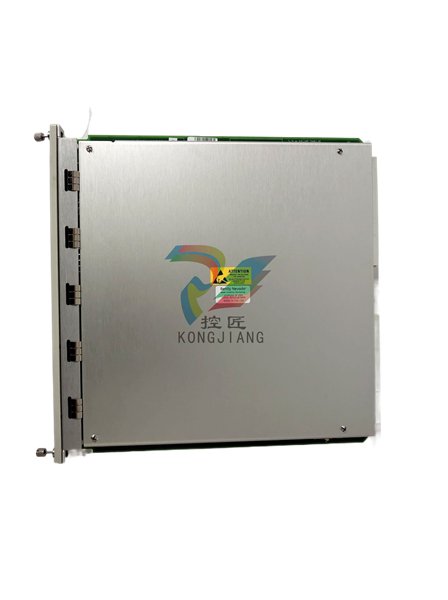

BENTLY Nevada 3300/16-15-01-03-00-00-00 Dual Channel Vibration Monitor Precision Engineering for Industrial Control Systems

Introducing the BENTLY Nevada 3300/16-15-01-03-00-00-00 Dual Channel Vibration Monitor, a robust and versatile solution for precise vibration monitoring in critical industrial applications. Designed to enhance the reliability and performance of your machinery, this dual-channel monitor is a key component of BENTLY automation products, ensuring that you maintain peak operational efficiency.

Key Technical Features:

The BENTLY Nevada 3300/16-15-01-03-00-00-00 is engineered with advanced technology to provide unparalleled performance in vibration analysis. Here are some of its standout features:

1. **Dual Channel Monitoring**: This device supports simultaneous monitoring of two channels, allowing for comprehensive analysis of machine conditions and reducing the need for multiple instruments.

2. **High Sensitivity**: With its high sensitivity capabilities, the monitor can detect minute vibrations that may indicate underlying mechanical issues, enabling early intervention before costly failures occur.

3. **Broad Frequency Range**: The wide frequency range of the 3300/16 model allows it to effectively analyze a variety of machinery, from slow-speed bearings to high-speed turbines, making it suitable for diverse applications.

4. **User-Friendly Interface**: The intuitive interface and display options facilitate easy setup and operation, ensuring that plant personnel can quickly get the monitor up and running with minimal training.

5. **Durability and Reliability**: Built for harsh industrial environments, the BENTLY Nevada 3300/16 is designed to withstand temperature fluctuations, dust, and moisture, ensuring reliable performance over time.

6. **Compatibility**: This model is compatible with other BENTLY products, allowing for seamless integration into existing monitoring systems, such as the BENTLY 3500 series, enhancing your overall vibration monitoring strategy.

Usage Scenarios:

The BENTLY Nevada 3300/16-15-01-03-00-00-00 is ideally suited for a range of applications across various industries, including:

– **Oil and Gas**: Monitor pumps, compressors, and turbines in oil rigs and refineries to ensure operational integrity and prevent downtime.

– **Power Generation**: Utilize the monitor in power plants to keep an eye on generators, turbines, and other critical assets, thus safeguarding against failure and extending equipment life.

– **Manufacturing**: In manufacturing environments, the monitor can be used to oversee rotating equipment, ensuring smooth operations and enhancing productivity.

– **Mining and Minerals**: Keep track of critical machinery such as crushers and conveyors, where vibration monitoring is key to maintaining efficiency and safety.

Comparison with Other Models:

When compared to other models in the BENTLY Nevada series, the 3300/16-15-01-03-00-00-00 stands out due to its dual-channel capability, which is particularly advantageous for monitoring complex systems that require simultaneous analysis of multiple parameters. For instance:

– **BENTLY 3500/20**: While the 3500/20 is a powerful single-channel monitor, it lacks the simultaneous monitoring feature of the 3300/16, making the latter a more flexible choice for intricate setups.

– **BENTLY 3500/42M**: This model is excellent for machinery protection, but the dual-channel feature of the 3300/16 allows users to monitor two points of data at once, providing greater insight into machinery health.

– **BENTLY 3500/25**: The 3500/25 is tailored for specific applications, while the versatility of the 3300/16 makes it suitable for a wider array of machinery.

Related Models:

To give you a better understanding of the BENTLY product lineup, here are ten related models that complement the capabilities of the BENTLY Nevada 3300/16:

1. **BENTLY 3500/20 125744-02**: A single-channel monitor ideal for basic applications.

2. **BENTLY 3500/45 176449-04**: Focused on machinery protection with advanced features.

3. **BENTLY 330500-00-00**: A versatile model within the Nevada series.

4. **BENTLY 3500/40M**: Designed for monitoring mechanical vibration in specific machinery.

5. **BENTLY 3500/92**: A high-performance model for critical applications.

6. **BENTLY 3500/50**: Focused on protecting rotating equipment.

7. **BENTLY 330130-040-00-00**: Another robust model in the 3300 series.

8. **BENTLY 3500/53**: Suitable for comprehensive monitoring of critical assets.

9. **BENTLY 3500/34**: A flexible model for various machine types.

10. **BENTLY 330104-00-25-10-02-00**: A well-rounded option for standard vibration monitoring needs.

In conclusion, the BENTLY Nevada 3300/16-15-01-03-00-00-00 Dual Channel Vibration Monitor is an essential tool for industries that rely on the optimal performance of machinery. With its advanced features, user-friendly design, and robust construction, it is well-equipped to meet the demands of modern industrial environments. Whether you are looking to enhance reliability in oil and gas, power generation, manufacturing, or mining, this monitor stands as a premier choice among BENTLY automation products, ensuring your operations run smoothly and efficiently.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY Nevada 3300/16-15-01-03-00-00-00 is engineered with advanced technology to provide unparalleled performance in vibration analysis. Here are some of its standout features:

1. **Dual Channel Monitoring**: This device supports simultaneous monitoring of two channels, allowing for comprehensive analysis of machine conditions and reducing the need for multiple instruments.

2. **High Sensitivity**: With its high sensitivity capabilities, the monitor can detect minute vibrations that may indicate underlying mechanical issues, enabling early intervention before costly failures occur.

3. **Broad Frequency Range**: The wide frequency range of the 3300/16 model allows it to effectively analyze a variety of machinery, from slow-speed bearings to high-speed turbines, making it suitable for diverse applications.

4. **User-Friendly Interface**: The intuitive interface and display options facilitate easy setup and operation, ensuring that plant personnel can quickly get the monitor up and running with minimal training.

5. **Durability and Reliability**: Built for harsh industrial environments, the BENTLY Nevada 3300/16 is designed to withstand temperature fluctuations, dust, and moisture, ensuring reliable performance over time.

6. **Compatibility**: This model is compatible with other BENTLY products, allowing for seamless integration into existing monitoring systems, such as the BENTLY 3500 series, enhancing your overall vibration monitoring strategy.

Usage Scenarios:

The BENTLY Nevada 3300/16-15-01-03-00-00-00 is ideally suited for a range of applications across various industries, including:

– **Oil and Gas**: Monitor pumps, compressors, and turbines in oil rigs and refineries to ensure operational integrity and prevent downtime.

– **Power Generation**: Utilize the monitor in power plants to keep an eye on generators, turbines, and other critical assets, thus safeguarding against failure and extending equipment life.

– **Manufacturing**: In manufacturing environments, the monitor can be used to oversee rotating equipment, ensuring smooth operations and enhancing productivity.

– **Mining and Minerals**: Keep track of critical machinery such as crushers and conveyors, where vibration monitoring is key to maintaining efficiency and safety.

Comparison with Other Models:

When compared to other models in the BENTLY Nevada series, the 3300/16-15-01-03-00-00-00 stands out due to its dual-channel capability, which is particularly advantageous for monitoring complex systems that require simultaneous analysis of multiple parameters. For instance:

– **BENTLY 3500/20**: While the 3500/20 is a powerful single-channel monitor, it lacks the simultaneous monitoring feature of the 3300/16, making the latter a more flexible choice for intricate setups.

– **BENTLY 3500/42M**: This model is excellent for machinery protection, but the dual-channel feature of the 3300/16 allows users to monitor two points of data at once, providing greater insight into machinery health.

– **BENTLY 3500/25**: The 3500/25 is tailored for specific applications, while the versatility of the 3300/16 makes it suitable for a wider array of machinery.

Related Models:

To give you a better understanding of the BENTLY product lineup, here are ten related models that complement the capabilities of the BENTLY Nevada 3300/16:

1. **BENTLY 3500/20 125744-02**: A single-channel monitor ideal for basic applications.

2. **BENTLY 3500/45 176449-04**: Focused on machinery protection with advanced features.

3. **BENTLY 330500-00-00**: A versatile model within the Nevada series.

4. **BENTLY 3500/40M**: Designed for monitoring mechanical vibration in specific machinery.

5. **BENTLY 3500/92**: A high-performance model for critical applications.

6. **BENTLY 3500/50**: Focused on protecting rotating equipment.

7. **BENTLY 330130-040-00-00**: Another robust model in the 3300 series.

8. **BENTLY 3500/53**: Suitable for comprehensive monitoring of critical assets.

9. **BENTLY 3500/34**: A flexible model for various machine types.

10. **BENTLY 330104-00-25-10-02-00**: A well-rounded option for standard vibration monitoring needs.

In conclusion, the BENTLY Nevada 3300/16-15-01-03-00-00-00 Dual Channel Vibration Monitor is an essential tool for industries that rely on the optimal performance of machinery. With its advanced features, user-friendly design, and robust construction, it is well-equipped to meet the demands of modern industrial environments. Whether you are looking to enhance reliability in oil and gas, power generation, manufacturing, or mining, this monitor stands as a premier choice among BENTLY automation products, ensuring your operations run smoothly and efficiently.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.