BENTLY Nevada 3300/20-05-03-01-00-00 3300 XL 8 mm Probe

Introducing the BENTLY Nevada: The Pinnacle of Condition Monitoring Technology

When it comes to advanced condition monitoring solutions, BENTLY Nevada stands at the forefront, delivering unmatched reliability and precision. This model is specifically engineered to meet the rigorous demands of industries such as oil and gas, power generation, and manufacturing. With a suite of key technical features, versatile usage scenarios, and a comprehensive comparison with other models, the BENTLY Nevada is your go-to choice for enhanced operational efficiency and safety.

Key Technical Features

The BENTLY Nevada is equipped with cutting-edge technology that sets it apart from the competition. Its robust architecture includes:

1. **Vibration Monitoring**: The BENTLY Nevada excels in real-time vibration analysis, allowing for the early detection of mechanical faults. With superior sensitivity and accuracy, it can identify issues before they escalate into costly failures.

2. **Multi-Channel Capability**: This model supports multiple channels, enabling simultaneous monitoring of various machinery components. This feature is crucial for complex systems where multiple parameters need to be tracked at once.

3. **Advanced Signal Processing**: Utilizing state-of-the-art algorithms, the BENTLY Nevada processes signals to provide clear and actionable insights. Its advanced filtering techniques minimize noise interference, ensuring data accuracy.

4. **User-Friendly Interface**: Designed with the operator in mind, the BENTLY Nevada offers an intuitive user interface that simplifies setup and data interpretation. This feature enhances user engagement, making the monitoring process straightforward and efficient.

5. **Robust Communication Protocols**: The BENTLY Nevada is compatible with various communication protocols, including Ethernet and Modbus, allowing seamless integration into existing automation systems. This flexibility makes it a perfect fit for modern industrial environments.

6. **Durable Build Quality**: Built to withstand harsh industrial conditions, the BENTLY Nevada features a rugged design that ensures long-lasting performance. Its robust casing protects against dust, moisture, and extreme temperatures, making it ideal for demanding applications.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide range of applications. Here are some common usage scenarios:

1. **Rotating Machinery Monitoring**: Ideal for turbines, compressors, and pumps, the BENTLY Nevada provides continuous monitoring to detect imbalance, misalignment, and bearing wear, ensuring optimal performance and longevity.

2. **Predictive Maintenance**: By analyzing vibration data, the BENTLY Nevada helps organizations implement predictive maintenance strategies. This proactive approach reduces downtime and maintenance costs, leading to significant operational savings.

3. **Safety Monitoring**: In industries where machinery failure can lead to catastrophic events, the BENTLY Nevada serves as a critical safety tool. Its real-time monitoring capabilities allow for immediate responses to potential hazards, safeguarding personnel and assets.

4. **Process Optimization**: The data collected by the BENTLY Nevada can be used to optimize processes, improving overall efficiency. By identifying inefficiencies, businesses can make informed decisions to enhance productivity and reduce waste.

Comparison with Other Models

When comparing the BENTLY Nevada to other models in the BENTLY family, it's evident that it holds a unique position. While models such as the BENTLY 3500/20 and BENTLY 3500/45 focus on specific aspects of machinery monitoring, the BENTLY Nevada offers a comprehensive solution that integrates multiple functionalities into one robust unit.

For instance, the BENTLY 3500/50 is excellent for machine protection, but it lacks the advanced signal processing capabilities of the BENTLY Nevada. Similarly, while the BENTLY 3300 series provides reliable vibration monitoring, it does not match the multi-channel support and user-friendly interface of the BENTLY Nevada.

The BENTLY Nevada also stands out when compared to models like the BENTLY 3500/42M and BENTLY 3500/34, which are designed for specific applications. The Nevada's versatility and all-encompassing monitoring capabilities make it the ideal choice for organizations looking for a holistic solution.

Reference to Related Models

To further understand how the BENTLY Nevada fits into the broader landscape of BENTLY automation products, consider the following related models:

1. **BENTLY 3500/20 125744-02**: Focused on machine protection with specific monitoring capabilities.

2. **BENTLY 3500/45 176449-04**: Designed for advanced machinery diagnostics.

3. **BENTLY 330500-00-00**: A versatile model offering basic vibration monitoring.

4. **BENTLY 3500/53 133388-01**: Provides enhanced monitoring features for rotating machinery.

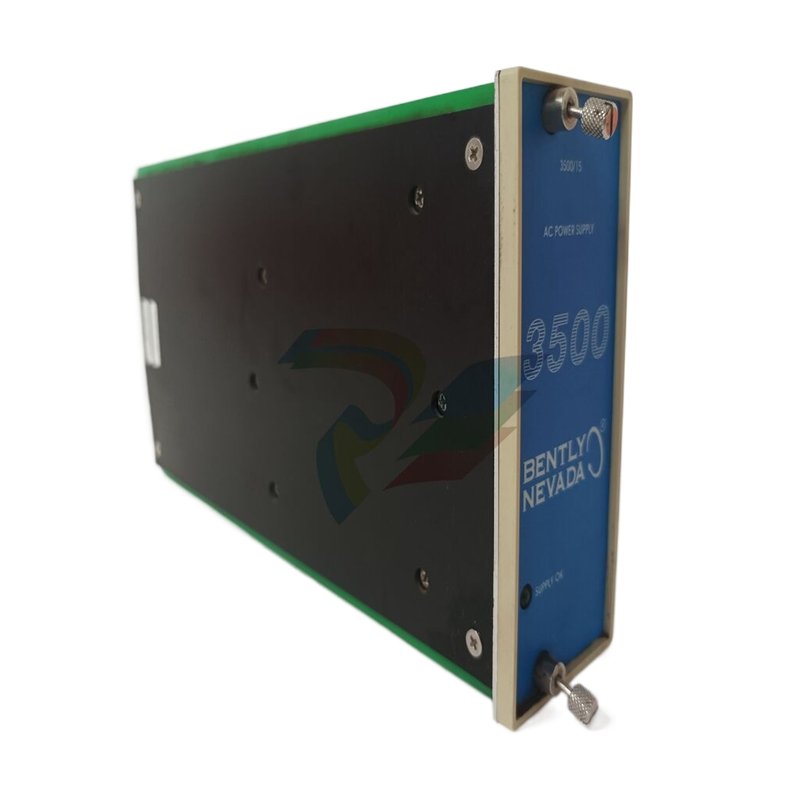

5. **BENTLY 3500/15**: A reliable model for vibration analysis in industrial applications.

6. **BENTLY 3500/92**: Offers comprehensive monitoring solutions for critical assets.

7. **BENTLY 3500/25**: Aimed at machinery protection with limited monitoring capabilities.

8. **BENTLY 3500/40M**: A robust model designed for various industrial applications.

9. **BENTLY 3300/16-11-01-03-00-00-01**: A compact solution for basic vibration monitoring.

10. **BENTLY 3500/77M**: Tailored for specific monitoring applications in industrial settings.

In conclusion, the BENTLY Nevada is more than just a condition monitoring device; it is an essential tool for modern industrial operations. With its advanced features, versatility, and superior performance, the BENTLY Nevada empowers organizations to elevate their maintenance strategies, enhance safety, and optimize processes. When paired with other BENTLY automation products, it creates a powerful ecosystem designed to maximize productivity and reliability in today’s demanding industrial landscape. Choose the BENTLY Nevada for an unparalleled monitoring experience that drives operational excellence.

The above parameters are for reference only. Please contact our technical team for precise selection.

When it comes to advanced condition monitoring solutions, BENTLY Nevada stands at the forefront, delivering unmatched reliability and precision. This model is specifically engineered to meet the rigorous demands of industries such as oil and gas, power generation, and manufacturing. With a suite of key technical features, versatile usage scenarios, and a comprehensive comparison with other models, the BENTLY Nevada is your go-to choice for enhanced operational efficiency and safety.

Key Technical Features

The BENTLY Nevada is equipped with cutting-edge technology that sets it apart from the competition. Its robust architecture includes:

1. **Vibration Monitoring**: The BENTLY Nevada excels in real-time vibration analysis, allowing for the early detection of mechanical faults. With superior sensitivity and accuracy, it can identify issues before they escalate into costly failures.

2. **Multi-Channel Capability**: This model supports multiple channels, enabling simultaneous monitoring of various machinery components. This feature is crucial for complex systems where multiple parameters need to be tracked at once.

3. **Advanced Signal Processing**: Utilizing state-of-the-art algorithms, the BENTLY Nevada processes signals to provide clear and actionable insights. Its advanced filtering techniques minimize noise interference, ensuring data accuracy.

4. **User-Friendly Interface**: Designed with the operator in mind, the BENTLY Nevada offers an intuitive user interface that simplifies setup and data interpretation. This feature enhances user engagement, making the monitoring process straightforward and efficient.

5. **Robust Communication Protocols**: The BENTLY Nevada is compatible with various communication protocols, including Ethernet and Modbus, allowing seamless integration into existing automation systems. This flexibility makes it a perfect fit for modern industrial environments.

6. **Durable Build Quality**: Built to withstand harsh industrial conditions, the BENTLY Nevada features a rugged design that ensures long-lasting performance. Its robust casing protects against dust, moisture, and extreme temperatures, making it ideal for demanding applications.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide range of applications. Here are some common usage scenarios:

1. **Rotating Machinery Monitoring**: Ideal for turbines, compressors, and pumps, the BENTLY Nevada provides continuous monitoring to detect imbalance, misalignment, and bearing wear, ensuring optimal performance and longevity.

2. **Predictive Maintenance**: By analyzing vibration data, the BENTLY Nevada helps organizations implement predictive maintenance strategies. This proactive approach reduces downtime and maintenance costs, leading to significant operational savings.

3. **Safety Monitoring**: In industries where machinery failure can lead to catastrophic events, the BENTLY Nevada serves as a critical safety tool. Its real-time monitoring capabilities allow for immediate responses to potential hazards, safeguarding personnel and assets.

4. **Process Optimization**: The data collected by the BENTLY Nevada can be used to optimize processes, improving overall efficiency. By identifying inefficiencies, businesses can make informed decisions to enhance productivity and reduce waste.

Comparison with Other Models

When comparing the BENTLY Nevada to other models in the BENTLY family, it's evident that it holds a unique position. While models such as the BENTLY 3500/20 and BENTLY 3500/45 focus on specific aspects of machinery monitoring, the BENTLY Nevada offers a comprehensive solution that integrates multiple functionalities into one robust unit.

For instance, the BENTLY 3500/50 is excellent for machine protection, but it lacks the advanced signal processing capabilities of the BENTLY Nevada. Similarly, while the BENTLY 3300 series provides reliable vibration monitoring, it does not match the multi-channel support and user-friendly interface of the BENTLY Nevada.

The BENTLY Nevada also stands out when compared to models like the BENTLY 3500/42M and BENTLY 3500/34, which are designed for specific applications. The Nevada's versatility and all-encompassing monitoring capabilities make it the ideal choice for organizations looking for a holistic solution.

Reference to Related Models

To further understand how the BENTLY Nevada fits into the broader landscape of BENTLY automation products, consider the following related models:

1. **BENTLY 3500/20 125744-02**: Focused on machine protection with specific monitoring capabilities.

2. **BENTLY 3500/45 176449-04**: Designed for advanced machinery diagnostics.

3. **BENTLY 330500-00-00**: A versatile model offering basic vibration monitoring.

4. **BENTLY 3500/53 133388-01**: Provides enhanced monitoring features for rotating machinery.

5. **BENTLY 3500/15**: A reliable model for vibration analysis in industrial applications.

6. **BENTLY 3500/92**: Offers comprehensive monitoring solutions for critical assets.

7. **BENTLY 3500/25**: Aimed at machinery protection with limited monitoring capabilities.

8. **BENTLY 3500/40M**: A robust model designed for various industrial applications.

9. **BENTLY 3300/16-11-01-03-00-00-01**: A compact solution for basic vibration monitoring.

10. **BENTLY 3500/77M**: Tailored for specific monitoring applications in industrial settings.

In conclusion, the BENTLY Nevada is more than just a condition monitoring device; it is an essential tool for modern industrial operations. With its advanced features, versatility, and superior performance, the BENTLY Nevada empowers organizations to elevate their maintenance strategies, enhance safety, and optimize processes. When paired with other BENTLY automation products, it creates a powerful ecosystem designed to maximize productivity and reliability in today’s demanding industrial landscape. Choose the BENTLY Nevada for an unparalleled monitoring experience that drives operational excellence.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.