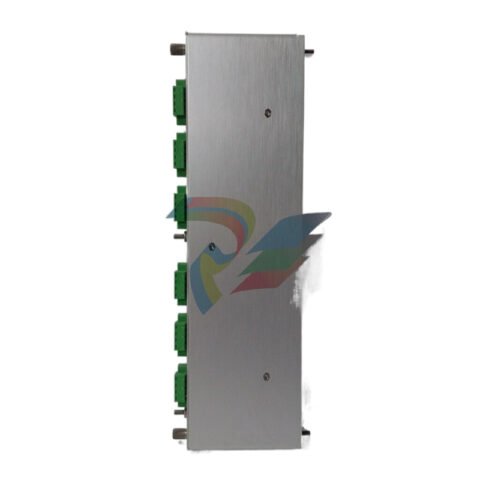

BENTLY Nevada 330102-00-20-10-01-00 Control Cable

Introducing the BENTLY Nevada: Elevate Your Monitoring with Precision and Reliability

The BENTLY Nevada model represents the pinnacle of condition monitoring and machinery protection technology. As part of BENTLY's esteemed line of automation products, the Nevada model is designed to deliver unparalleled performance and reliability in the most demanding industrial environments.

Key Technical Features

At the heart of the BENTLY Nevada is its cutting-edge technology, which includes advanced vibration analysis, dynamic performance monitoring, and comprehensive diagnostic capabilities. This model is equipped with high-resolution sensors that provide real-time data on machine performance, allowing for proactive maintenance and minimizing downtime.

Key features of the BENTLY Nevada include:

1. **Robust Sensor Technology**: The Nevada model utilizes high-quality sensors capable of measuring vibration, temperature, and other critical parameters. This ensures accurate monitoring of machinery health and performance.

2. **Advanced Signal Processing**: With sophisticated algorithms, the BENTLY Nevada processes data to detect anomalies and predict potential failures before they occur. This predictive capability is crucial for maintaining operational efficiency.

3. **User-Friendly Interface**: The intuitive interface of the Nevada model makes it easy for operators to access data and generate reports, facilitating informed decision-making.

4. **Scalability**: The BENTLY Nevada is designed to be scalable, allowing integration into existing systems and providing flexibility as monitoring needs evolve.

5. **Durability**: Built to withstand harsh industrial environments, the BENTLY Nevada is resistant to dust, moisture, and temperature fluctuations, ensuring consistent performance in a variety of settings.

Usage Scenarios

The BENTLY Nevada excels in a multitude of applications across various industries. It is particularly effective in sectors such as oil and gas, power generation, and manufacturing, where machinery reliability is crucial.

1. **Oil and Gas**: In the oil and gas industry, the BENTLY Nevada continuously monitors critical rotating equipment, such as pumps and compressors, providing early warnings of potential issues that could lead to costly shutdowns.

2. **Power Generation**: The model is essential in power plants, where it monitors turbines and generators, ensuring they operate within safe parameters and optimizing energy production.

3. **Manufacturing**: In manufacturing settings, the BENTLY Nevada helps maintain the health of production machinery, reducing maintenance costs and improving uptime.

4. **Mining Operations**: For mining companies, the Nevada model provides vital insights into the performance of heavy machinery, helping to prevent unexpected failures that could disrupt operations.

Comparison with Other Models

When comparing the BENTLY Nevada to other models within the BENTLY lineup, its advanced capabilities set it apart. For instance, while the BENTLY 3500/20 125744-02 focuses primarily on vibration monitoring, the Nevada model offers a more comprehensive suite of features, including temperature monitoring and predictive analytics.

In contrast to the BENTLY 3500/45 176449-04, which is designed for basic condition monitoring, the Nevada model's advanced algorithms and user-friendly interface provide a more robust solution for operators seeking to enhance their maintenance strategies. Models such as the BENTLY 3500/50 and BENTLY 3500/40M also serve specific monitoring needs but lack the full range of capabilities that the Nevada offers.

Moreover, the BENTLY 330500-00-00 is tailored for specific applications, while the BENTLY Nevada is versatile enough to adapt to various industrial needs, making it a more appealing choice for organizations looking to invest in comprehensive monitoring solutions.

Related Models

For those exploring the world of BENTLY automation products, several related models are worth considering:

1. **BENTLY 3500/20 125744-02** – Ideal for vibration monitoring applications, providing foundational insights into machinery health.

2. **BENTLY 3500/45 176449-04** – Focuses on machinery condition monitoring and is suitable for various industrial environments.

3. **BENTLY 3500/50** – Offers enhanced data collection features for advanced monitoring scenarios.

4. **BENTLY 3500/40M** – Specializes in dynamic performance monitoring with real-time diagnostics.

5. **BENTLY 3500/22M** – Designed for machine protection, ensuring critical equipment remains operational.

6. **BENTLY 3500/15** – A reliable choice for basic monitoring applications within less demanding environments.

7. **BENTLY 3500/53** – Provides extensive data collection capabilities, ideal for complex monitoring setups.

8. **BENTLY 3500/92** – Focuses on advanced diagnostics, providing in-depth analysis for machinery performance.

9. **BENTLY 3500/34** – Tailored for specific applications, offering a more focused monitoring solution.

10. **BENTLY 3300/20-12-01** – A versatile option for general condition monitoring in various industrial setups.

Conclusion

The BENTLY Nevada is the ultimate solution for organizations seeking to enhance their machinery monitoring capabilities. With its advanced technical features, adaptability to various industries, and robust performance, the Nevada model stands out as a leading choice among BENTLY automation products. By investing in the BENTLY Nevada, businesses can ensure operational efficiency, reduce maintenance costs, and maximize the lifespan of their critical assets. Elevate your monitoring strategies today with the unparalleled reliability of the BENTLY Nevada.

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY Nevada model represents the pinnacle of condition monitoring and machinery protection technology. As part of BENTLY's esteemed line of automation products, the Nevada model is designed to deliver unparalleled performance and reliability in the most demanding industrial environments.

Key Technical Features

At the heart of the BENTLY Nevada is its cutting-edge technology, which includes advanced vibration analysis, dynamic performance monitoring, and comprehensive diagnostic capabilities. This model is equipped with high-resolution sensors that provide real-time data on machine performance, allowing for proactive maintenance and minimizing downtime.

Key features of the BENTLY Nevada include:

1. **Robust Sensor Technology**: The Nevada model utilizes high-quality sensors capable of measuring vibration, temperature, and other critical parameters. This ensures accurate monitoring of machinery health and performance.

2. **Advanced Signal Processing**: With sophisticated algorithms, the BENTLY Nevada processes data to detect anomalies and predict potential failures before they occur. This predictive capability is crucial for maintaining operational efficiency.

3. **User-Friendly Interface**: The intuitive interface of the Nevada model makes it easy for operators to access data and generate reports, facilitating informed decision-making.

4. **Scalability**: The BENTLY Nevada is designed to be scalable, allowing integration into existing systems and providing flexibility as monitoring needs evolve.

5. **Durability**: Built to withstand harsh industrial environments, the BENTLY Nevada is resistant to dust, moisture, and temperature fluctuations, ensuring consistent performance in a variety of settings.

Usage Scenarios

The BENTLY Nevada excels in a multitude of applications across various industries. It is particularly effective in sectors such as oil and gas, power generation, and manufacturing, where machinery reliability is crucial.

1. **Oil and Gas**: In the oil and gas industry, the BENTLY Nevada continuously monitors critical rotating equipment, such as pumps and compressors, providing early warnings of potential issues that could lead to costly shutdowns.

2. **Power Generation**: The model is essential in power plants, where it monitors turbines and generators, ensuring they operate within safe parameters and optimizing energy production.

3. **Manufacturing**: In manufacturing settings, the BENTLY Nevada helps maintain the health of production machinery, reducing maintenance costs and improving uptime.

4. **Mining Operations**: For mining companies, the Nevada model provides vital insights into the performance of heavy machinery, helping to prevent unexpected failures that could disrupt operations.

Comparison with Other Models

When comparing the BENTLY Nevada to other models within the BENTLY lineup, its advanced capabilities set it apart. For instance, while the BENTLY 3500/20 125744-02 focuses primarily on vibration monitoring, the Nevada model offers a more comprehensive suite of features, including temperature monitoring and predictive analytics.

In contrast to the BENTLY 3500/45 176449-04, which is designed for basic condition monitoring, the Nevada model's advanced algorithms and user-friendly interface provide a more robust solution for operators seeking to enhance their maintenance strategies. Models such as the BENTLY 3500/50 and BENTLY 3500/40M also serve specific monitoring needs but lack the full range of capabilities that the Nevada offers.

Moreover, the BENTLY 330500-00-00 is tailored for specific applications, while the BENTLY Nevada is versatile enough to adapt to various industrial needs, making it a more appealing choice for organizations looking to invest in comprehensive monitoring solutions.

Related Models

For those exploring the world of BENTLY automation products, several related models are worth considering:

1. **BENTLY 3500/20 125744-02** – Ideal for vibration monitoring applications, providing foundational insights into machinery health.

2. **BENTLY 3500/45 176449-04** – Focuses on machinery condition monitoring and is suitable for various industrial environments.

3. **BENTLY 3500/50** – Offers enhanced data collection features for advanced monitoring scenarios.

4. **BENTLY 3500/40M** – Specializes in dynamic performance monitoring with real-time diagnostics.

5. **BENTLY 3500/22M** – Designed for machine protection, ensuring critical equipment remains operational.

6. **BENTLY 3500/15** – A reliable choice for basic monitoring applications within less demanding environments.

7. **BENTLY 3500/53** – Provides extensive data collection capabilities, ideal for complex monitoring setups.

8. **BENTLY 3500/92** – Focuses on advanced diagnostics, providing in-depth analysis for machinery performance.

9. **BENTLY 3500/34** – Tailored for specific applications, offering a more focused monitoring solution.

10. **BENTLY 3300/20-12-01** – A versatile option for general condition monitoring in various industrial setups.

Conclusion

The BENTLY Nevada is the ultimate solution for organizations seeking to enhance their machinery monitoring capabilities. With its advanced technical features, adaptability to various industries, and robust performance, the Nevada model stands out as a leading choice among BENTLY automation products. By investing in the BENTLY Nevada, businesses can ensure operational efficiency, reduce maintenance costs, and maximize the lifespan of their critical assets. Elevate your monitoring strategies today with the unparalleled reliability of the BENTLY Nevada.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.