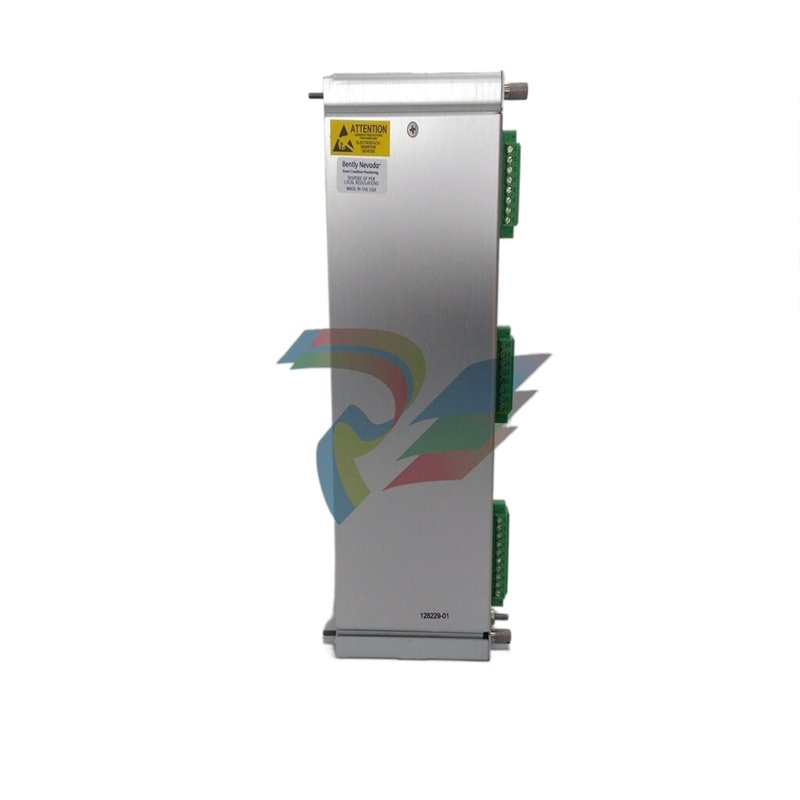

BENTLY Nevada 330130-00-03-10-02-CN, XL Extension Cable for Vibration Monitoring

Introducing the BENTLY Nevada: A Pinnacle of Precision in Condition Monitoring

In the realm of industrial automation, the BENTLY Nevada series stands as a hallmark of excellence, precision, and reliability. The BENTLY Nevada model is designed to enhance operational efficiency and ensure the optimal performance of your machinery through advanced condition monitoring systems. This innovative product combines cutting-edge technology with user-friendly features, making it an indispensable tool for industries reliant on machinery and equipment performance.

Key Technical Features

The BENTLY Nevada model is equipped with a comprehensive suite of technical features that set it apart in the market of condition monitoring systems:

1. **Advanced Vibration Analysis**: With high-frequency data acquisition capabilities, the BENTLY Nevada excels in capturing critical vibration data. This feature enables early detection of potential failures, allowing for timely maintenance interventions and reducing unexpected downtimes.

2. **Real-Time Monitoring**: The system provides real-time monitoring capabilities, delivering immediate insights into machine health and performance. This ensures that operators can make informed decisions based on current data rather than relying solely on historical trends.

3. **Flexible Sensor Integration**: The BENTLY Nevada supports a wide range of sensors, allowing for customized solutions tailored to specific machinery and operational needs. This flexibility ensures that users can monitor various parameters, including displacement, velocity, and acceleration.

4. **Robust Data Logging**: With extensive data logging capabilities, the BENTLY Nevada model captures and stores historical data for trend analysis. Users can review past performances, identify patterns, and make strategic adjustments to maintenance schedules.

5. **User-Friendly Interface**: The intuitive interface of the BENTLY Nevada enhances user experience, making it easy for operators to navigate through settings, access reports, and analyze data efficiently.

6. **Durability and Reliability**: Built to withstand harsh industrial environments, the BENTLY Nevada is designed with robust materials and components, ensuring longevity and consistent performance even in the most challenging conditions.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide array of industrial applications. Here are some notable usage scenarios:

1. **Power Generation**: In power plants, the BENTLY Nevada system can monitor turbine and generator performance, detecting imbalances and potential failures before they escalate into costly outages.

2. **Oil and Gas**: For oil and gas extraction operations, the BENTLY Nevada plays a critical role in monitoring equipment such as pumps and compressors, ensuring operational efficiency and safety in demanding environments.

3. **Manufacturing**: In manufacturing facilities, the BENTLY Nevada system aids in the monitoring of conveyor systems, motors, and other critical machinery, helping to minimize operational interruptions and enhance productivity.

4. **Chemical Processing**: The BENTLY Nevada is instrumental in monitoring reactors and distillation columns in chemical processing plants, ensuring that equipment operates within safe parameters and adheres to regulatory standards.

5. **Mining Operations**: In the mining sector, the BENTLY Nevada model can be used to monitor heavy machinery, such as excavators and haul trucks, optimizing maintenance schedules and improving overall equipment effectiveness.

Comparison with Other Models

When compared to other models within the BENTLY product line, the BENTLY Nevada stands out due to its advanced features and robust performance. For instance, while the BENTLY 3500/20 provides reliable vibration monitoring, the BENTLY Nevada offers enhanced data acquisition and real-time monitoring capabilities, making it a more comprehensive solution for critical machinery.

Another notable comparison can be made with the BENTLY 3500/40M, which focuses primarily on vibration monitoring and protection. The BENTLY Nevada, on the other hand, integrates a wider range of sensors and monitoring parameters, making it a more versatile option for diverse industrial applications.

Additionally, when looking at the BENTLY 3500/53, known for its machine condition monitoring, the BENTLY Nevada offers superior data logging capabilities and an easier-to-navigate user interface, allowing operators to access critical information swiftly.

Related Models

The BENTLY Nevada is part of a broader family of BENTLY automation products that cater to various monitoring needs. Here are ten related models that complement the BENTLY Nevada:

1. **BENTLY 3500/20 125744-02**: A reliable choice for vibration monitoring.

2. **BENTLY 3500/40M 176449-01**: Features advanced monitoring for critical machines.

3. **BENTLY 3500/53**: Known for its comprehensive condition monitoring.

4. **BENTLY 3500/25**: Offers protection and monitoring solutions.

5. **BENTLY 3300/20-12-01**: A robust option for general vibration monitoring.

6. **BENTLY 3500/45 176449-04**: Focuses on machinery protection systems.

7. **BENTLY 3500/22M**: Designed for machinery performance monitoring.

8. **BENTLY 330500-00-00**: Provides advanced data acquisition capabilities.

9. **BENTLY 3500/15**: Ideal for basic vibration monitoring needs.

10. **BENTLY 3500/92**: A specialized model for enhanced monitoring applications.

Conclusion

In summary, the BENTLY Nevada model is an exemplary product within the BENTLY automation products line, offering advanced features, extensive usage scenarios, and unparalleled reliability. Its capability to enhance operational efficiency across various industries makes it a must-have for organizations seeking to improve their machinery performance and minimize downtime. By choosing the BENTLY Nevada, users invest in a future of proactive maintenance and enhanced productivity, setting a new standard in condition monitoring systems.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the realm of industrial automation, the BENTLY Nevada series stands as a hallmark of excellence, precision, and reliability. The BENTLY Nevada model is designed to enhance operational efficiency and ensure the optimal performance of your machinery through advanced condition monitoring systems. This innovative product combines cutting-edge technology with user-friendly features, making it an indispensable tool for industries reliant on machinery and equipment performance.

Key Technical Features

The BENTLY Nevada model is equipped with a comprehensive suite of technical features that set it apart in the market of condition monitoring systems:

1. **Advanced Vibration Analysis**: With high-frequency data acquisition capabilities, the BENTLY Nevada excels in capturing critical vibration data. This feature enables early detection of potential failures, allowing for timely maintenance interventions and reducing unexpected downtimes.

2. **Real-Time Monitoring**: The system provides real-time monitoring capabilities, delivering immediate insights into machine health and performance. This ensures that operators can make informed decisions based on current data rather than relying solely on historical trends.

3. **Flexible Sensor Integration**: The BENTLY Nevada supports a wide range of sensors, allowing for customized solutions tailored to specific machinery and operational needs. This flexibility ensures that users can monitor various parameters, including displacement, velocity, and acceleration.

4. **Robust Data Logging**: With extensive data logging capabilities, the BENTLY Nevada model captures and stores historical data for trend analysis. Users can review past performances, identify patterns, and make strategic adjustments to maintenance schedules.

5. **User-Friendly Interface**: The intuitive interface of the BENTLY Nevada enhances user experience, making it easy for operators to navigate through settings, access reports, and analyze data efficiently.

6. **Durability and Reliability**: Built to withstand harsh industrial environments, the BENTLY Nevada is designed with robust materials and components, ensuring longevity and consistent performance even in the most challenging conditions.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide array of industrial applications. Here are some notable usage scenarios:

1. **Power Generation**: In power plants, the BENTLY Nevada system can monitor turbine and generator performance, detecting imbalances and potential failures before they escalate into costly outages.

2. **Oil and Gas**: For oil and gas extraction operations, the BENTLY Nevada plays a critical role in monitoring equipment such as pumps and compressors, ensuring operational efficiency and safety in demanding environments.

3. **Manufacturing**: In manufacturing facilities, the BENTLY Nevada system aids in the monitoring of conveyor systems, motors, and other critical machinery, helping to minimize operational interruptions and enhance productivity.

4. **Chemical Processing**: The BENTLY Nevada is instrumental in monitoring reactors and distillation columns in chemical processing plants, ensuring that equipment operates within safe parameters and adheres to regulatory standards.

5. **Mining Operations**: In the mining sector, the BENTLY Nevada model can be used to monitor heavy machinery, such as excavators and haul trucks, optimizing maintenance schedules and improving overall equipment effectiveness.

Comparison with Other Models

When compared to other models within the BENTLY product line, the BENTLY Nevada stands out due to its advanced features and robust performance. For instance, while the BENTLY 3500/20 provides reliable vibration monitoring, the BENTLY Nevada offers enhanced data acquisition and real-time monitoring capabilities, making it a more comprehensive solution for critical machinery.

Another notable comparison can be made with the BENTLY 3500/40M, which focuses primarily on vibration monitoring and protection. The BENTLY Nevada, on the other hand, integrates a wider range of sensors and monitoring parameters, making it a more versatile option for diverse industrial applications.

Additionally, when looking at the BENTLY 3500/53, known for its machine condition monitoring, the BENTLY Nevada offers superior data logging capabilities and an easier-to-navigate user interface, allowing operators to access critical information swiftly.

Related Models

The BENTLY Nevada is part of a broader family of BENTLY automation products that cater to various monitoring needs. Here are ten related models that complement the BENTLY Nevada:

1. **BENTLY 3500/20 125744-02**: A reliable choice for vibration monitoring.

2. **BENTLY 3500/40M 176449-01**: Features advanced monitoring for critical machines.

3. **BENTLY 3500/53**: Known for its comprehensive condition monitoring.

4. **BENTLY 3500/25**: Offers protection and monitoring solutions.

5. **BENTLY 3300/20-12-01**: A robust option for general vibration monitoring.

6. **BENTLY 3500/45 176449-04**: Focuses on machinery protection systems.

7. **BENTLY 3500/22M**: Designed for machinery performance monitoring.

8. **BENTLY 330500-00-00**: Provides advanced data acquisition capabilities.

9. **BENTLY 3500/15**: Ideal for basic vibration monitoring needs.

10. **BENTLY 3500/92**: A specialized model for enhanced monitoring applications.

Conclusion

In summary, the BENTLY Nevada model is an exemplary product within the BENTLY automation products line, offering advanced features, extensive usage scenarios, and unparalleled reliability. Its capability to enhance operational efficiency across various industries makes it a must-have for organizations seeking to improve their machinery performance and minimize downtime. By choosing the BENTLY Nevada, users invest in a future of proactive maintenance and enhanced productivity, setting a new standard in condition monitoring systems.

The above parameters are for reference only. Please contact our technical team for precise selection.

-480x480.jpg)

There are no reviews yet.