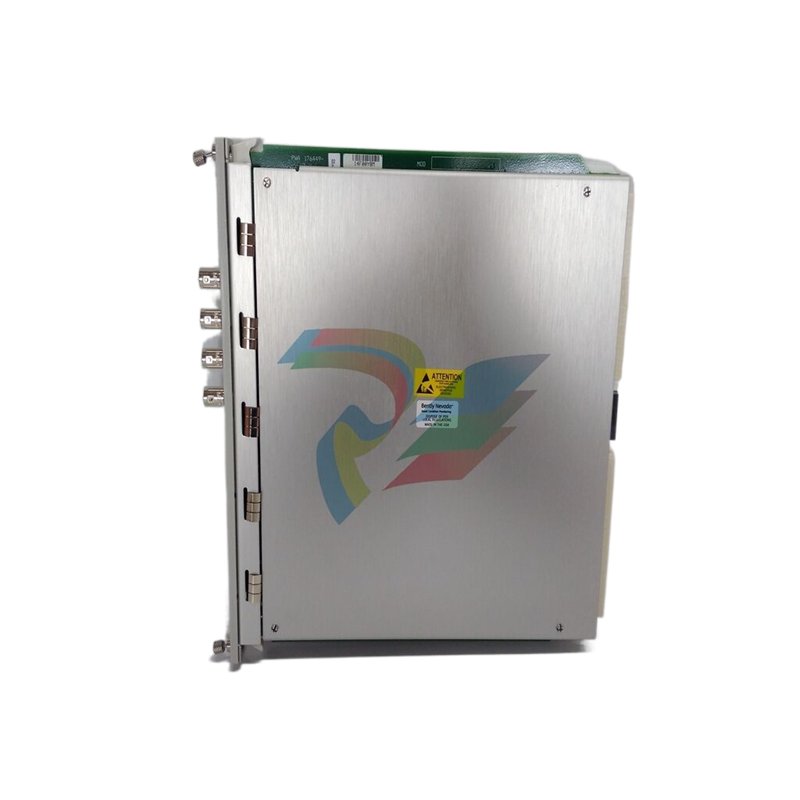

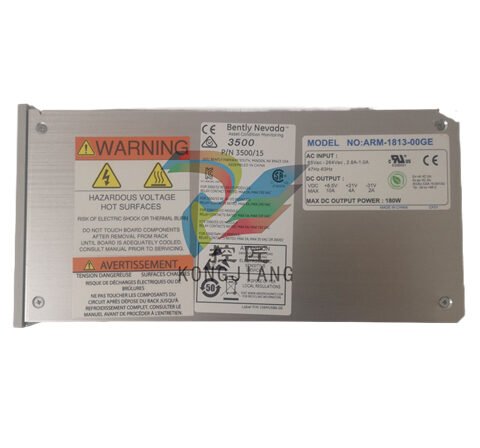

BENTLY Nevada 33180-51-00 3300XL Proximitor Sensor

Introducing the BENTLY Nevada 33180-51-00 – a pinnacle of precision and reliability in the world of condition monitoring and predictive maintenance. This advanced sensor system is engineered to enhance operational efficiency while minimizing downtime in industrial applications. Whether you're monitoring machinery vibrations, temperature, or other critical parameters, the BENTLY Nevada 33180-51-00 is designed to deliver exceptional performance.

Key Technical Features

The BENTLY Nevada 33180-51-00 is packed with cutting-edge technology that sets it apart from the competition. It features high-resolution vibration sensors capable of measuring a wide frequency range, ensuring accurate data capture for predictive maintenance. The device is equipped with advanced signal processing algorithms that filter out noise and optimize data for reliable diagnostics. Its robust construction ensures durability in harsh industrial environments, making it suitable for various applications.

With its user-friendly interface, the BENTLY Nevada 33180-51-00 simplifies installation and configuration. The device supports multiple communication protocols, including Modbus and Ethernet, allowing seamless integration with existing BENTLY automation products. Additionally, it features extensive data logging capabilities, enabling users to analyze historical performance trends easily.

Usage Scenarios

The BENTLY Nevada 33180-51-00 is ideal for a wide range of applications across various industries, including oil and gas, power generation, and manufacturing. In oil and gas, it can be used to monitor the health of pumps, compressors, and turbines, ensuring optimal performance and preventing costly failures. In power generation, this device plays a crucial role in monitoring turbines and generators, where even minor irregularities can lead to significant operational disruptions.

Manufacturing facilities can also benefit from the BENTLY Nevada 33180-51-00 by implementing predictive maintenance strategies that reduce downtime and enhance productivity. By continuously monitoring machinery, operators can identify potential issues before they escalate, saving time and resources. Its versatility makes it an essential tool for any organization looking to improve operational efficiency and reliability.

Comparison with Other Models

When comparing the BENTLY Nevada 33180-51-00 with other models in the BENTLY lineup, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/40M, the differences become apparent. While the 3500 series is renowned for its extensive functionality and scalability, the 33180-51-00 provides a more specialized approach to condition monitoring, focusing specifically on vibration analysis.

For instance, the BENTLY 3500/45 176449-04 offers a broader range of monitoring capabilities, including temperature and pressure, making it suitable for applications requiring comprehensive data collection. In contrast, the BENTLY Nevada 33180-51-00 excels at delivering precise vibration measurements, making it the go-to choice for vibration-centric applications.

Another notable comparison is with the BENTLY 3500/22M, which is optimized for monitoring rotating machinery. While both devices offer high-quality data and reliability, the BENTLY Nevada 33180-51-00's advanced signal processing capabilities give it an edge in environments where noise reduction is critical.

Reference to Related Models

The BENTLY Nevada 33180-51-00 fits seamlessly into the extensive BENTLY automation products ecosystem. Related models that complement its functionality include:

1. BENTLY 3500/20 125744-02 – A versatile monitoring system for various parameters.

2. BENTLY 3500/40M – Known for its advanced machinery health monitoring.

3. BENTLY 3500/25 – Offers comprehensive data logging capabilities.

4. BENTLY 3500/92 – A dedicated solution for monitoring rotating equipment.

5. BENTLY 330500-00-00 – Designed for critical machinery applications.

6. BENTLY 3500/53 – Provides enhanced vibration monitoring features.

7. BENTLY 3500/34 – A reliable choice for condition monitoring in complex environments.

8. BENTLY 3500/42M – Focused on turbine monitoring applications.

9. BENTLY 3300/16-11-01-03-00-00-01 – Ideal for applications requiring high accuracy.

10. BENTLY 3500/72M – Offers advanced diagnostics and monitoring solutions.

These models work in tandem with the BENTLY Nevada 33180-51-00, providing a comprehensive suite of monitoring solutions for various industrial applications.

Conclusion

In today's fast-paced industrial environment, ensuring the reliability and efficiency of machinery is paramount. The BENTLY Nevada 33180-51-00 stands out as a premier choice for those seeking to implement advanced predictive maintenance strategies. Its robust technical features, versatility in usage scenarios, and compatibility with other BENTLY automation products make it an indispensable asset for industries ranging from oil and gas to manufacturing.

By investing in the BENTLY Nevada 33180-51-00, organizations can harness the power of state-of-the-art vibration monitoring technology, ensuring their operations run smoothly and efficiently. Don't let machinery failures disrupt your productivity – choose the BENTLY Nevada 33180-51-00 for unparalleled reliability and performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada 33180-51-00 is packed with cutting-edge technology that sets it apart from the competition. It features high-resolution vibration sensors capable of measuring a wide frequency range, ensuring accurate data capture for predictive maintenance. The device is equipped with advanced signal processing algorithms that filter out noise and optimize data for reliable diagnostics. Its robust construction ensures durability in harsh industrial environments, making it suitable for various applications.

With its user-friendly interface, the BENTLY Nevada 33180-51-00 simplifies installation and configuration. The device supports multiple communication protocols, including Modbus and Ethernet, allowing seamless integration with existing BENTLY automation products. Additionally, it features extensive data logging capabilities, enabling users to analyze historical performance trends easily.

Usage Scenarios

The BENTLY Nevada 33180-51-00 is ideal for a wide range of applications across various industries, including oil and gas, power generation, and manufacturing. In oil and gas, it can be used to monitor the health of pumps, compressors, and turbines, ensuring optimal performance and preventing costly failures. In power generation, this device plays a crucial role in monitoring turbines and generators, where even minor irregularities can lead to significant operational disruptions.

Manufacturing facilities can also benefit from the BENTLY Nevada 33180-51-00 by implementing predictive maintenance strategies that reduce downtime and enhance productivity. By continuously monitoring machinery, operators can identify potential issues before they escalate, saving time and resources. Its versatility makes it an essential tool for any organization looking to improve operational efficiency and reliability.

Comparison with Other Models

When comparing the BENTLY Nevada 33180-51-00 with other models in the BENTLY lineup, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/40M, the differences become apparent. While the 3500 series is renowned for its extensive functionality and scalability, the 33180-51-00 provides a more specialized approach to condition monitoring, focusing specifically on vibration analysis.

For instance, the BENTLY 3500/45 176449-04 offers a broader range of monitoring capabilities, including temperature and pressure, making it suitable for applications requiring comprehensive data collection. In contrast, the BENTLY Nevada 33180-51-00 excels at delivering precise vibration measurements, making it the go-to choice for vibration-centric applications.

Another notable comparison is with the BENTLY 3500/22M, which is optimized for monitoring rotating machinery. While both devices offer high-quality data and reliability, the BENTLY Nevada 33180-51-00's advanced signal processing capabilities give it an edge in environments where noise reduction is critical.

Reference to Related Models

The BENTLY Nevada 33180-51-00 fits seamlessly into the extensive BENTLY automation products ecosystem. Related models that complement its functionality include:

1. BENTLY 3500/20 125744-02 – A versatile monitoring system for various parameters.

2. BENTLY 3500/40M – Known for its advanced machinery health monitoring.

3. BENTLY 3500/25 – Offers comprehensive data logging capabilities.

4. BENTLY 3500/92 – A dedicated solution for monitoring rotating equipment.

5. BENTLY 330500-00-00 – Designed for critical machinery applications.

6. BENTLY 3500/53 – Provides enhanced vibration monitoring features.

7. BENTLY 3500/34 – A reliable choice for condition monitoring in complex environments.

8. BENTLY 3500/42M – Focused on turbine monitoring applications.

9. BENTLY 3300/16-11-01-03-00-00-01 – Ideal for applications requiring high accuracy.

10. BENTLY 3500/72M – Offers advanced diagnostics and monitoring solutions.

These models work in tandem with the BENTLY Nevada 33180-51-00, providing a comprehensive suite of monitoring solutions for various industrial applications.

Conclusion

In today's fast-paced industrial environment, ensuring the reliability and efficiency of machinery is paramount. The BENTLY Nevada 33180-51-00 stands out as a premier choice for those seeking to implement advanced predictive maintenance strategies. Its robust technical features, versatility in usage scenarios, and compatibility with other BENTLY automation products make it an indispensable asset for industries ranging from oil and gas to manufacturing.

By investing in the BENTLY Nevada 33180-51-00, organizations can harness the power of state-of-the-art vibration monitoring technology, ensuring their operations run smoothly and efficiently. Don't let machinery failures disrupt your productivity – choose the BENTLY Nevada 33180-51-00 for unparalleled reliability and performance.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.