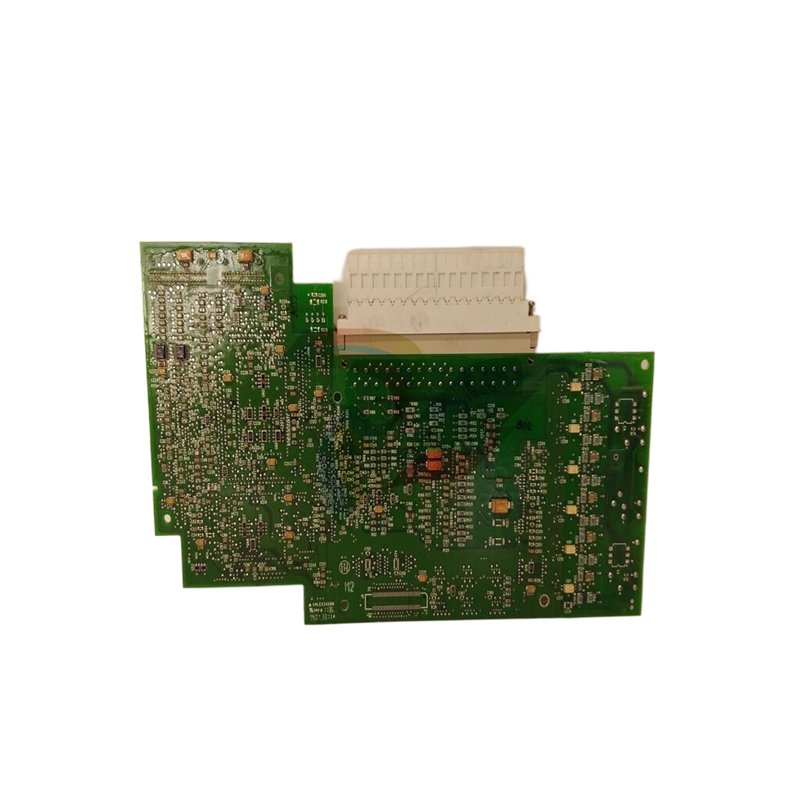

BENTLY Nevada 3500/25-01-02-00 Advanced Keyphasor Module, Engineered for Precision Control Solutions

Introducing the BENTLY Nevada 3500/25-01-02-00: The Future of Condition Monitoring

The BENTLY Nevada 3500/25-01-02-00 is a cutting-edge condition monitoring system designed to optimize the performance and reliability of critical machinery in industrial applications. As part of the renowned BENTLY automation products line, this model brings exceptional precision, versatility, and ease of use to your maintenance strategy.

Key Technical Features

The BENTLY Nevada 3500/25-01-02-00 is engineered with a range of advanced features that set it apart from other models in the BENTLY family. This system offers:

1. **Multi-channel Capability**: With the ability to monitor multiple parameters simultaneously, the 3500/25 model allows for comprehensive analysis of machine health, reducing downtime and improving operational efficiency.

2. **High Accuracy and Sensitivity**: Utilizing advanced sensors and algorithms, this model ensures precise measurements of vibration, temperature, and other critical indicators, enabling early detection of potential issues.

3. **Robust Data Acquisition**: The system can capture and store data over extended periods, providing a wealth of information for trend analysis and predictive maintenance strategies.

4. **User-Friendly Interface**: Designed with ease of use in mind, the BENTLY Nevada 3500/25-01-02-00 features an intuitive interface that allows operators to quickly interpret data and respond to alerts.

5. **Versatile Communication Options**: With support for various communication protocols, including Ethernet and Modbus, integration with existing control systems is seamless, allowing for real-time monitoring and control.

6. **Environmental Resilience**: Built to withstand harsh industrial conditions, the BENTLY Nevada 3500/25-01-02-00 is equipped with robust housing and components resistant to dust, moisture, and temperature fluctuations.

Usage Scenarios

The BENTLY Nevada 3500/25-01-02-00 is ideally suited for a range of industrial applications, including:

1. **Power Generation**: In power plants, the model can monitor turbines, generators, and pumps, ensuring optimal performance and early detection of mechanical failures.

2. **Oil and Gas**: Used in refineries and offshore platforms, it provides critical insights into the condition of compressors, pumps, and drilling equipment, preventing costly shutdowns.

3. **Manufacturing**: In manufacturing settings, the system can monitor conveyor belts, motors, and machinery, enhancing productivity by reducing unplanned maintenance.

4. **Aerospace and Defense**: The BENTLY Nevada 3500/25-01-02-00 is also applicable in aerospace and defense sectors, ensuring the reliability of critical systems and components.

5. **Mining and Metals**: For mining operations, this system monitors heavy machinery and equipment, optimizing performance and extending equipment life.

Comparison with Other Models

When comparing the BENTLY Nevada 3500/25-01-02-00 with other models in the BENTLY lineup, such as the BENTLY 3500/20 125744-02 and the BENTLY 3500/40M, several distinctions emerge.

The 3500/25-01-02-00 stands out with its advanced multi-channel monitoring capabilities, making it an ideal choice for facilities that require extensive surveillance of multiple assets. In contrast, the BENTLY 3500/20 125744-02 is typically designed for specific applications, providing effective monitoring for individual machines but lacking the expansive functionality of the 3500/25 series.

Additionally, the BENTLY 3500/40M focuses on high-speed data acquisition for rotating equipment, making it suitable for applications where rapid response is crucial. However, for organizations seeking a comprehensive solution that includes versatility and ease of integration, the BENTLY Nevada 3500/25-01-02-00 is the superior choice.

Related Models

For those interested in exploring additional options within the BENTLY automation products range, consider the following models:

1. **BENTLY 3500/20 125744-02** – Ideal for specific machine monitoring applications.

2. **BENTLY 3500/45 176449-04** – Designed for advanced vibration monitoring.

3. **BENTLY 3500/42M** – A reliable option for critical machine health monitoring.

4. **BENTLY 3500/40M** – Focused on high-speed data acquisition for rotating equipment.

5. **BENTLY 3500/92** – Offers enhanced monitoring and diagnostics.

6. **BENTLY 3500/53 133388-01** – A high-performance model for machinery health.

7. **BENTLY 3500/15** – A compact solution for basic monitoring needs.

8. **BENTLY 3500/34** – Offers comprehensive monitoring for various machinery.

9. **BENTLY 3500/50** – Provides versatile monitoring with a focus on reliability.

10. **BENTLY 3500/25-01-00-00** – A foundational model with essential monitoring features.

Conclusion

The BENTLY Nevada 3500/25-01-02-00 represents a significant advancement in condition monitoring technology, offering unparalleled features, versatility, and reliability. Whether in power generation, oil and gas, manufacturing, or other industrial sectors, this model stands poised to enhance operational efficiency and reduce maintenance costs. With its robust capabilities and user-friendly design, the BENTLY Nevada 3500/25-01-02-00 is the ultimate choice for organizations committed to optimizing their asset performance and ensuring the longevity of their critical machinery. Experience the future of condition monitoring with BENTLY automation products.

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY Nevada 3500/25-01-02-00 is a cutting-edge condition monitoring system designed to optimize the performance and reliability of critical machinery in industrial applications. As part of the renowned BENTLY automation products line, this model brings exceptional precision, versatility, and ease of use to your maintenance strategy.

Key Technical Features

The BENTLY Nevada 3500/25-01-02-00 is engineered with a range of advanced features that set it apart from other models in the BENTLY family. This system offers:

1. **Multi-channel Capability**: With the ability to monitor multiple parameters simultaneously, the 3500/25 model allows for comprehensive analysis of machine health, reducing downtime and improving operational efficiency.

2. **High Accuracy and Sensitivity**: Utilizing advanced sensors and algorithms, this model ensures precise measurements of vibration, temperature, and other critical indicators, enabling early detection of potential issues.

3. **Robust Data Acquisition**: The system can capture and store data over extended periods, providing a wealth of information for trend analysis and predictive maintenance strategies.

4. **User-Friendly Interface**: Designed with ease of use in mind, the BENTLY Nevada 3500/25-01-02-00 features an intuitive interface that allows operators to quickly interpret data and respond to alerts.

5. **Versatile Communication Options**: With support for various communication protocols, including Ethernet and Modbus, integration with existing control systems is seamless, allowing for real-time monitoring and control.

6. **Environmental Resilience**: Built to withstand harsh industrial conditions, the BENTLY Nevada 3500/25-01-02-00 is equipped with robust housing and components resistant to dust, moisture, and temperature fluctuations.

Usage Scenarios

The BENTLY Nevada 3500/25-01-02-00 is ideally suited for a range of industrial applications, including:

1. **Power Generation**: In power plants, the model can monitor turbines, generators, and pumps, ensuring optimal performance and early detection of mechanical failures.

2. **Oil and Gas**: Used in refineries and offshore platforms, it provides critical insights into the condition of compressors, pumps, and drilling equipment, preventing costly shutdowns.

3. **Manufacturing**: In manufacturing settings, the system can monitor conveyor belts, motors, and machinery, enhancing productivity by reducing unplanned maintenance.

4. **Aerospace and Defense**: The BENTLY Nevada 3500/25-01-02-00 is also applicable in aerospace and defense sectors, ensuring the reliability of critical systems and components.

5. **Mining and Metals**: For mining operations, this system monitors heavy machinery and equipment, optimizing performance and extending equipment life.

Comparison with Other Models

When comparing the BENTLY Nevada 3500/25-01-02-00 with other models in the BENTLY lineup, such as the BENTLY 3500/20 125744-02 and the BENTLY 3500/40M, several distinctions emerge.

The 3500/25-01-02-00 stands out with its advanced multi-channel monitoring capabilities, making it an ideal choice for facilities that require extensive surveillance of multiple assets. In contrast, the BENTLY 3500/20 125744-02 is typically designed for specific applications, providing effective monitoring for individual machines but lacking the expansive functionality of the 3500/25 series.

Additionally, the BENTLY 3500/40M focuses on high-speed data acquisition for rotating equipment, making it suitable for applications where rapid response is crucial. However, for organizations seeking a comprehensive solution that includes versatility and ease of integration, the BENTLY Nevada 3500/25-01-02-00 is the superior choice.

Related Models

For those interested in exploring additional options within the BENTLY automation products range, consider the following models:

1. **BENTLY 3500/20 125744-02** – Ideal for specific machine monitoring applications.

2. **BENTLY 3500/45 176449-04** – Designed for advanced vibration monitoring.

3. **BENTLY 3500/42M** – A reliable option for critical machine health monitoring.

4. **BENTLY 3500/40M** – Focused on high-speed data acquisition for rotating equipment.

5. **BENTLY 3500/92** – Offers enhanced monitoring and diagnostics.

6. **BENTLY 3500/53 133388-01** – A high-performance model for machinery health.

7. **BENTLY 3500/15** – A compact solution for basic monitoring needs.

8. **BENTLY 3500/34** – Offers comprehensive monitoring for various machinery.

9. **BENTLY 3500/50** – Provides versatile monitoring with a focus on reliability.

10. **BENTLY 3500/25-01-00-00** – A foundational model with essential monitoring features.

Conclusion

The BENTLY Nevada 3500/25-01-02-00 represents a significant advancement in condition monitoring technology, offering unparalleled features, versatility, and reliability. Whether in power generation, oil and gas, manufacturing, or other industrial sectors, this model stands poised to enhance operational efficiency and reduce maintenance costs. With its robust capabilities and user-friendly design, the BENTLY Nevada 3500/25-01-02-00 is the ultimate choice for organizations committed to optimizing their asset performance and ensuring the longevity of their critical machinery. Experience the future of condition monitoring with BENTLY automation products.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.