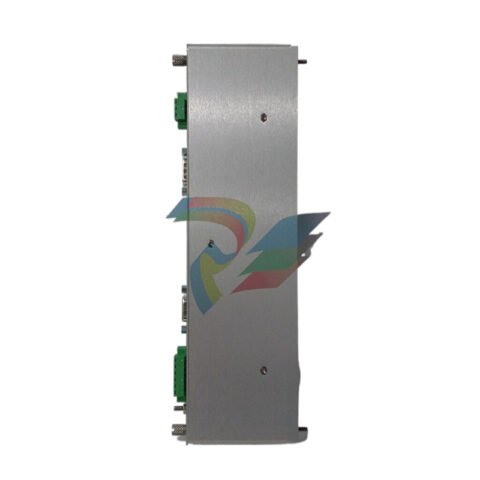

BENTLY Nevada 3500/33-01-01 16-Channel Relay Module for Industrial Control

Introducing the BENTLY Nevada 3500/33-01-01: advanced machinery condition monitoring for the modern industrial landscape. Designed for seamless integration into your operational framework, the BENTLY Nevada 3500/33-01-01 is an essential tool for optimizing the performance and safety of critical rotating machinery. With its robust features and exceptional reliability, this model stands out among BENTLY automation products, catering to industries such as oil and gas, power generation, and manufacturing.

Key Technical Features:

The BENTLY Nevada 3500/33-01-01 boasts a range of impressive specifications that position it at the forefront of condition monitoring technology. This model features high-fidelity vibration measurement capabilities, allowing it to capture real-time data with unparalleled accuracy. The device supports a variety of sensors, including proximity probes and accelerometers, ensuring comprehensive monitoring of machine health.

One of the standout features of the 3500/33-01-01 is its advanced signal processing capabilities. Equipped with sophisticated algorithms, this model can analyze vibration patterns and detect anomalies, providing early warning signals of potential equipment failures. This proactive approach not only enhances machinery lifespan but also minimizes costly downtime associated with unexpected breakdowns.

The BENTLY Nevada 3500/33-01-01 also offers exceptional flexibility. Its modular architecture allows for easy scalability, enabling businesses to expand their monitoring system as their operational needs evolve. Furthermore, the device is compatible with the extensive BENTLY 3500 series, making it a versatile choice for organizations that already utilize other models within the family. The intuitive user interface simplifies operation and provides a seamless experience for technicians and engineers alike.

Usage Scenarios:

The versatility of the BENTLY Nevada 3500/33-01-01 makes it suitable for various industrial applications. In power generation facilities, for instance, this model can be used to monitor gas and steam turbines, ensuring optimal performance and safety. In the oil and gas sector, it effectively tracks the condition of pumps, compressors, and other critical machinery, safeguarding against failures that could lead to significant production losses.

In manufacturing environments, the 3500/33-01-01 is invaluable for monitoring conveyor systems, robotic arms, and other automated processes. By providing real-time insights into machine health, operators can schedule maintenance during non-peak hours, optimizing productivity and reducing operational costs. Moreover, the device's ability to integrate with existing automation systems ensures that it becomes a vital component of an organization's overall predictive maintenance strategy.

Comparison with Other Models:

When compared to other models within the BENTLY Nevada series, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/45 176449-04, the 3500/33-01-01 distinguishes itself with its advanced vibration monitoring capabilities and modular flexibility. While the 3500/20 focuses primarily on machinery protection, the 3500/33-01-01 takes a more comprehensive approach, combining protection with detailed condition monitoring.

Additionally, the BENTLY 3500/40M and 3500/50 models are also notable for their monitoring functions; however, the 3500/33-01-01's superior signal processing and data analysis features give it an edge for businesses requiring in-depth insights into machine performance. Furthermore, for organizations already utilizing models like the BENTLY 3500/34 or the BENTLY 3500/42M, the 3500/33-01-01 seamlessly integrates into existing systems, enhancing overall monitoring capabilities.

Related Models:

If you're exploring options within the BENTLY automation products lineup, consider the following related models:

1. BENTLY 3500/20 125744-02 – Ideal for baseline protection applications.

2. BENTLY 3500/45 176449-04 – Focused on machinery protection and monitoring.

3. BENTLY 3500/34 – A reliable option for monitoring machinery health.

4. BENTLY 3500/42M – Provides robust monitoring for rotating equipment.

5. BENTLY 3500/40M – Known for its advanced diagnostics capabilities.

6. BENTLY 3500/50 – Offers comprehensive monitoring and protection features.

7. BENTLY 3500/92 – A great choice for critical machinery performance monitoring.

8. BENTLY 3500/25 – Designed for protection applications in various industries.

9. BENTLY 3500/53 – Integrates seamlessly into existing monitoring frameworks.

10. BENTLY 3500/72M – Known for its extensive monitoring capabilities across multiple applications.

In conclusion, the BENTLY Nevada 3500/33-01-01 is a cutting-edge solution for businesses looking to enhance their condition monitoring efforts. Its robust features, flexible design, and compatibility with other BENTLY automation products make it a standout choice for industries where machinery reliability is paramount. Invest in the BENTLY Nevada 3500/33-01-01 today and take a proactive step towards optimizing your operations, safeguarding your assets, and ensuring peak performance for years to come.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY Nevada 3500/33-01-01 boasts a range of impressive specifications that position it at the forefront of condition monitoring technology. This model features high-fidelity vibration measurement capabilities, allowing it to capture real-time data with unparalleled accuracy. The device supports a variety of sensors, including proximity probes and accelerometers, ensuring comprehensive monitoring of machine health.

One of the standout features of the 3500/33-01-01 is its advanced signal processing capabilities. Equipped with sophisticated algorithms, this model can analyze vibration patterns and detect anomalies, providing early warning signals of potential equipment failures. This proactive approach not only enhances machinery lifespan but also minimizes costly downtime associated with unexpected breakdowns.

The BENTLY Nevada 3500/33-01-01 also offers exceptional flexibility. Its modular architecture allows for easy scalability, enabling businesses to expand their monitoring system as their operational needs evolve. Furthermore, the device is compatible with the extensive BENTLY 3500 series, making it a versatile choice for organizations that already utilize other models within the family. The intuitive user interface simplifies operation and provides a seamless experience for technicians and engineers alike.

Usage Scenarios:

The versatility of the BENTLY Nevada 3500/33-01-01 makes it suitable for various industrial applications. In power generation facilities, for instance, this model can be used to monitor gas and steam turbines, ensuring optimal performance and safety. In the oil and gas sector, it effectively tracks the condition of pumps, compressors, and other critical machinery, safeguarding against failures that could lead to significant production losses.

In manufacturing environments, the 3500/33-01-01 is invaluable for monitoring conveyor systems, robotic arms, and other automated processes. By providing real-time insights into machine health, operators can schedule maintenance during non-peak hours, optimizing productivity and reducing operational costs. Moreover, the device's ability to integrate with existing automation systems ensures that it becomes a vital component of an organization's overall predictive maintenance strategy.

Comparison with Other Models:

When compared to other models within the BENTLY Nevada series, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/45 176449-04, the 3500/33-01-01 distinguishes itself with its advanced vibration monitoring capabilities and modular flexibility. While the 3500/20 focuses primarily on machinery protection, the 3500/33-01-01 takes a more comprehensive approach, combining protection with detailed condition monitoring.

Additionally, the BENTLY 3500/40M and 3500/50 models are also notable for their monitoring functions; however, the 3500/33-01-01's superior signal processing and data analysis features give it an edge for businesses requiring in-depth insights into machine performance. Furthermore, for organizations already utilizing models like the BENTLY 3500/34 or the BENTLY 3500/42M, the 3500/33-01-01 seamlessly integrates into existing systems, enhancing overall monitoring capabilities.

Related Models:

If you're exploring options within the BENTLY automation products lineup, consider the following related models:

1. BENTLY 3500/20 125744-02 – Ideal for baseline protection applications.

2. BENTLY 3500/45 176449-04 – Focused on machinery protection and monitoring.

3. BENTLY 3500/34 – A reliable option for monitoring machinery health.

4. BENTLY 3500/42M – Provides robust monitoring for rotating equipment.

5. BENTLY 3500/40M – Known for its advanced diagnostics capabilities.

6. BENTLY 3500/50 – Offers comprehensive monitoring and protection features.

7. BENTLY 3500/92 – A great choice for critical machinery performance monitoring.

8. BENTLY 3500/25 – Designed for protection applications in various industries.

9. BENTLY 3500/53 – Integrates seamlessly into existing monitoring frameworks.

10. BENTLY 3500/72M – Known for its extensive monitoring capabilities across multiple applications.

In conclusion, the BENTLY Nevada 3500/33-01-01 is a cutting-edge solution for businesses looking to enhance their condition monitoring efforts. Its robust features, flexible design, and compatibility with other BENTLY automation products make it a standout choice for industries where machinery reliability is paramount. Invest in the BENTLY Nevada 3500/33-01-01 today and take a proactive step towards optimizing your operations, safeguarding your assets, and ensuring peak performance for years to come.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.