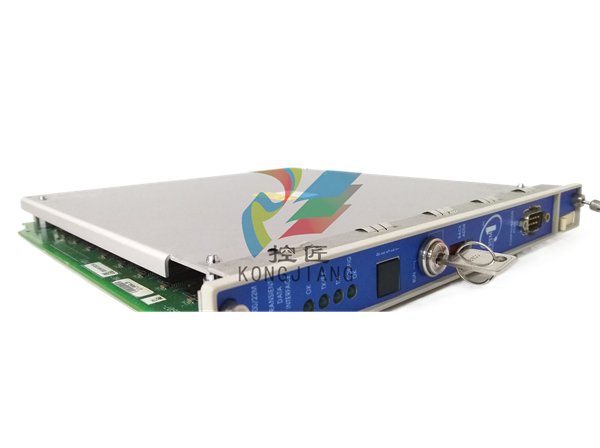

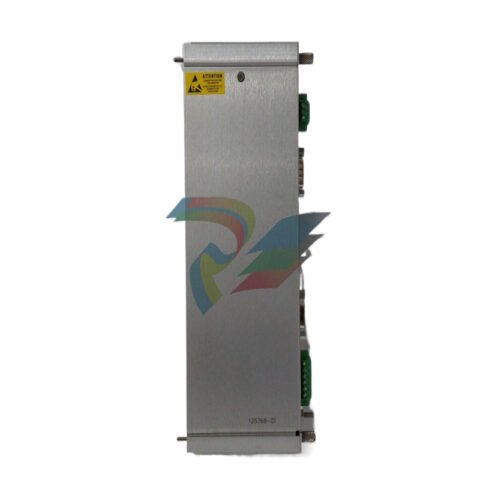

BENTLY Nevada 3500/61 I/O Module 136711-02, with Internal Barriers & Internal Terminations

Introducing the BENTLY Nevada: Your Premier Choice for Condition Monitoring and Asset Protection

In the world of industrial automation, reliability and precision are paramount. The BENTLY Nevada model stands out as a leading solution in condition monitoring and asset protection, designed to meet the rigorous demands of various sectors including oil and gas, power generation, and manufacturing. As an integral part of BENTLY automation products, the BENTLY Nevada provides unparalleled performance and peace of mind.

### Key Technical Features

The BENTLY Nevada is engineered with cutting-edge technology to deliver superior monitoring capabilities. Some of its standout features include:

1. **Advanced Vibration Monitoring**: The BENTLY Nevada is equipped with sophisticated vibration sensors that provide real-time data on equipment health. This allows for early detection of potential issues, reducing the risk of unexpected downtime.

2. **Integrated Data Acquisition**: With its multi-channel capabilities, the BENTLY Nevada can monitor multiple assets simultaneously, streamlining the monitoring process and enhancing operational efficiency.

3. **Ease of Installation and Use**: Designed for user-friendly integration, the BENTLY Nevada can be easily installed in existing setups without the need for extensive modifications. Its intuitive interface allows operators to quickly learn and utilize its features.

4. **Robust Communication Protocols**: The model supports various industry-standard communication protocols, ensuring compatibility with existing BENTLY automation products. This versatility allows for seamless integration into diverse monitoring systems.

5. **Scalability**: The BENTLY Nevada is designed for scalability, which means that as your operation grows, your monitoring system can expand without requiring a complete overhaul.

6. **Durability and Reliability**: Built to withstand harsh industrial environments, the BENTLY Nevada is housed in robust enclosures that protect it from dust, moisture, and extreme temperatures, ensuring reliable operation in demanding conditions.

### Usage Scenarios

The BENTLY Nevada finds application in numerous scenarios, making it a versatile choice for various industries. Here are some typical use cases:

– **Rotating Machinery Monitoring**: Essential for turbines, pumps, and compressors, the BENTLY Nevada monitors vibration levels to prevent catastrophic failures and maintain optimal performance.

– **Predictive Maintenance**: By continuously analyzing data, the BENTLY Nevada aids in predicting maintenance needs, allowing for planned downtime and minimizing production interruptions.

– **Asset Management**: Used by asset managers to ensure the integrity of critical machinery, the BENTLY Nevada provides insights that help in making informed decisions regarding equipment replacement or repair.

– **Industrial Automation**: In automated environments, the BENTLY Nevada can serve as a key component, working alongside other BENTLY automation products to create a holistic monitoring and control system.

### Comparison with Other Models

When compared with other models within the BENTLY product line, the BENTLY Nevada offers unique advantages tailored to specific monitoring needs. For example:

– **BENTLY 3500/20**: While the BENTLY 3500/20 focuses on specific monitoring parameters, the BENTLY Nevada provides a broader range of monitoring capabilities, making it ideal for complex systems.

– **BENTLY 3500/50**: Though similar in function, the BENTLY 3500/50 is often used in more specialized applications. The BENTLY Nevada, with its enhanced scalability, is better suited for operations that require adaptability as they grow.

– **BENTLY 3300/20**: The BENTLY 3300/20 is designed primarily for vibration monitoring, whereas the BENTLY Nevada encompasses a wider array of features, making it a more comprehensive solution for condition monitoring.

### Related Models

To understand how the BENTLY Nevada fits within the broader BENTLY automation products ecosystem, consider these related models:

1. **BENTLY 3500/45**: A high-performance model for machinery protection.

2. **BENTLY 3500/34**: Offers advanced monitoring for machinery in operation.

3. **BENTLY 330500-00-00**: A compact solution for vibration monitoring.

4. **BENTLY 3500/40M**: Focused on machinery health monitoring.

5. **BENTLY 3500/92**: Designed for advanced monitoring applications.

6. **BENTLY 3500/25**: Known for its reliability in critical applications.

7. **BENTLY 3500/53**: Tailored for specific monitoring requirements.

8. **BENTLY 3500/64M**: Integrates seamlessly into existing systems.

9. **BENTLY 3500/77M**: Provides robust monitoring for high-speed machinery.

10. **BENTLY 3300/16-11-01**: A versatile solution for various industrial settings.

### Conclusion

The BENTLY Nevada is more than just a monitoring solution; it is a comprehensive tool designed to enhance operational efficiency, ensure asset protection, and facilitate predictive maintenance across various industries. With its combination of advanced features, ease of use, and compatibility with other BENTLY automation products, the BENTLY Nevada stands as a beacon of reliability in condition monitoring.

Choose the BENTLY Nevada for your industrial automation needs and experience the difference that cutting-edge technology can make in maintaining your operations at peak performance. Embrace the future of monitoring with confidence, knowing that the BENTLY Nevada is your partner in achieving operational excellence.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the world of industrial automation, reliability and precision are paramount. The BENTLY Nevada model stands out as a leading solution in condition monitoring and asset protection, designed to meet the rigorous demands of various sectors including oil and gas, power generation, and manufacturing. As an integral part of BENTLY automation products, the BENTLY Nevada provides unparalleled performance and peace of mind.

### Key Technical Features

The BENTLY Nevada is engineered with cutting-edge technology to deliver superior monitoring capabilities. Some of its standout features include:

1. **Advanced Vibration Monitoring**: The BENTLY Nevada is equipped with sophisticated vibration sensors that provide real-time data on equipment health. This allows for early detection of potential issues, reducing the risk of unexpected downtime.

2. **Integrated Data Acquisition**: With its multi-channel capabilities, the BENTLY Nevada can monitor multiple assets simultaneously, streamlining the monitoring process and enhancing operational efficiency.

3. **Ease of Installation and Use**: Designed for user-friendly integration, the BENTLY Nevada can be easily installed in existing setups without the need for extensive modifications. Its intuitive interface allows operators to quickly learn and utilize its features.

4. **Robust Communication Protocols**: The model supports various industry-standard communication protocols, ensuring compatibility with existing BENTLY automation products. This versatility allows for seamless integration into diverse monitoring systems.

5. **Scalability**: The BENTLY Nevada is designed for scalability, which means that as your operation grows, your monitoring system can expand without requiring a complete overhaul.

6. **Durability and Reliability**: Built to withstand harsh industrial environments, the BENTLY Nevada is housed in robust enclosures that protect it from dust, moisture, and extreme temperatures, ensuring reliable operation in demanding conditions.

### Usage Scenarios

The BENTLY Nevada finds application in numerous scenarios, making it a versatile choice for various industries. Here are some typical use cases:

– **Rotating Machinery Monitoring**: Essential for turbines, pumps, and compressors, the BENTLY Nevada monitors vibration levels to prevent catastrophic failures and maintain optimal performance.

– **Predictive Maintenance**: By continuously analyzing data, the BENTLY Nevada aids in predicting maintenance needs, allowing for planned downtime and minimizing production interruptions.

– **Asset Management**: Used by asset managers to ensure the integrity of critical machinery, the BENTLY Nevada provides insights that help in making informed decisions regarding equipment replacement or repair.

– **Industrial Automation**: In automated environments, the BENTLY Nevada can serve as a key component, working alongside other BENTLY automation products to create a holistic monitoring and control system.

### Comparison with Other Models

When compared with other models within the BENTLY product line, the BENTLY Nevada offers unique advantages tailored to specific monitoring needs. For example:

– **BENTLY 3500/20**: While the BENTLY 3500/20 focuses on specific monitoring parameters, the BENTLY Nevada provides a broader range of monitoring capabilities, making it ideal for complex systems.

– **BENTLY 3500/50**: Though similar in function, the BENTLY 3500/50 is often used in more specialized applications. The BENTLY Nevada, with its enhanced scalability, is better suited for operations that require adaptability as they grow.

– **BENTLY 3300/20**: The BENTLY 3300/20 is designed primarily for vibration monitoring, whereas the BENTLY Nevada encompasses a wider array of features, making it a more comprehensive solution for condition monitoring.

### Related Models

To understand how the BENTLY Nevada fits within the broader BENTLY automation products ecosystem, consider these related models:

1. **BENTLY 3500/45**: A high-performance model for machinery protection.

2. **BENTLY 3500/34**: Offers advanced monitoring for machinery in operation.

3. **BENTLY 330500-00-00**: A compact solution for vibration monitoring.

4. **BENTLY 3500/40M**: Focused on machinery health monitoring.

5. **BENTLY 3500/92**: Designed for advanced monitoring applications.

6. **BENTLY 3500/25**: Known for its reliability in critical applications.

7. **BENTLY 3500/53**: Tailored for specific monitoring requirements.

8. **BENTLY 3500/64M**: Integrates seamlessly into existing systems.

9. **BENTLY 3500/77M**: Provides robust monitoring for high-speed machinery.

10. **BENTLY 3300/16-11-01**: A versatile solution for various industrial settings.

### Conclusion

The BENTLY Nevada is more than just a monitoring solution; it is a comprehensive tool designed to enhance operational efficiency, ensure asset protection, and facilitate predictive maintenance across various industries. With its combination of advanced features, ease of use, and compatibility with other BENTLY automation products, the BENTLY Nevada stands as a beacon of reliability in condition monitoring.

Choose the BENTLY Nevada for your industrial automation needs and experience the difference that cutting-edge technology can make in maintaining your operations at peak performance. Embrace the future of monitoring with confidence, knowing that the BENTLY Nevada is your partner in achieving operational excellence.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.