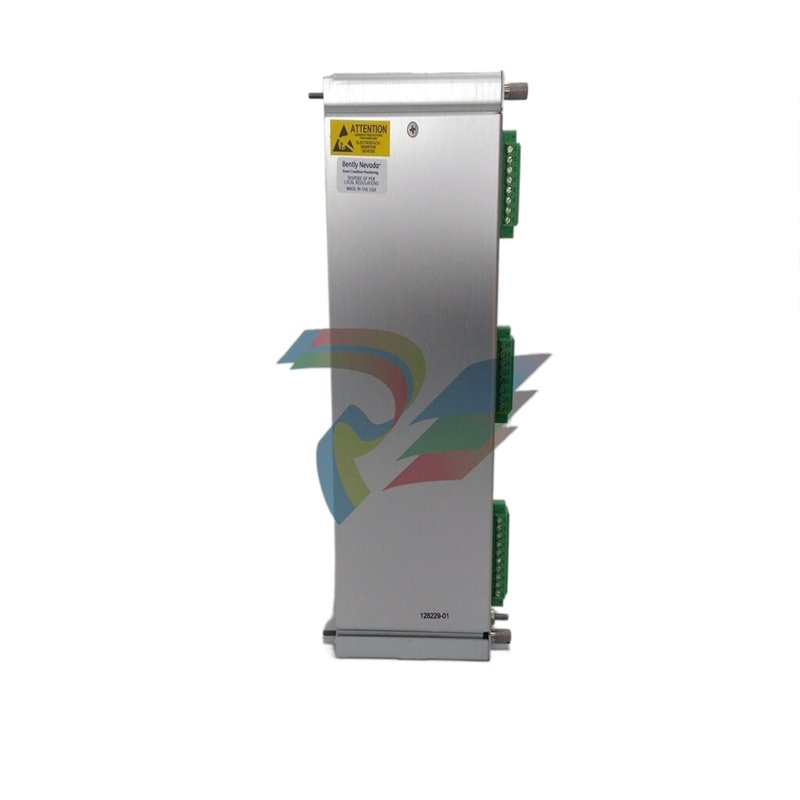

BENTLY Nevada Proximity Probes 330104-08-14-10-02-05, Advanced Automation Solution

Introducing the BENTLY Nevada: The Pinnacle of Condition Monitoring and Predictive Maintenance

In the realm of industrial automation and predictive maintenance, the BENTLY Nevada series stands as a benchmark for excellence. Renowned for its unparalleled reliability and advanced monitoring capabilities, the BENTLY Nevada model is engineered to enhance the performance and longevity of critical machinery across various sectors. This product description delves into the key technical features, usage scenarios, comparisons with other models, and a comprehensive overview of related models within the BENTLY automation products lineup.

Key Technical Features

The BENTLY Nevada model is equipped with state-of-the-art technology that ensures precise monitoring and analysis of rotating machinery. Key technical features include:

1. **Advanced Vibration Monitoring**: The BENTLY Nevada employs sophisticated vibration sensors and analytics to detect even the slightest changes in machinery performance. This enables early identification of potential issues before they escalate into costly failures.

2. **Real-Time Data Acquisition**: With its robust data acquisition capabilities, the BENTLY Nevada can provide real-time insights into your machinery's health. This feature is critical for industries where downtime can lead to significant financial losses.

3. **User-Friendly Interface**: The BENTLY Nevada is designed with an intuitive user interface that simplifies monitoring and data interpretation. Operators can easily navigate through the system, ensuring quick access to critical information.

4. **Scalability**: Whether you’re managing a single machine or an entire fleet, the BENTLY Nevada is scalable to meet your needs. This flexibility allows businesses to expand their monitoring capabilities as they grow.

5. **Integration with Existing Systems**: The BENTLY Nevada is compatible with other BENTLY automation products, making it an ideal choice for businesses that already utilize BENTLY solutions. It can seamlessly integrate into existing monitoring frameworks for enhanced efficiency.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide range of applications across various industries. Key usage scenarios include:

– **Power Generation**: In power plants, the BENTLY Nevada monitors turbine and generator performance, ensuring optimal operation and preventing unplanned outages.

– **Oil and Gas**: The model is invaluable in the oil and gas sector, where it safeguards critical machinery such as pumps, compressors, and drilling rigs by providing continuous health assessments.

– **Manufacturing**: In manufacturing environments, the BENTLY Nevada can be used to monitor motors, conveyors, and other moving equipment, ensuring they operate smoothly and efficiently.

– **Water and Wastewater Treatment**: The BENTLY Nevada helps maintain the performance of pumps and treatment equipment, ensuring safe and efficient operations.

– **Mining and Metals**: In the mining sector, it can monitor crushers, conveyors, and other vital equipment, optimizing performance and minimizing downtime.

Comparison with Other Models

When compared to other models within the BENTLY series, the BENTLY Nevada distinguishes itself through its advanced analytics and real-time monitoring capabilities. For example, the BENTLY 3500/20 125744-02 is known for its reliability but may not offer the same level of real-time data and user-friendly interface as the Nevada model. Similarly, while the BENTLY 3500/50 and 3500/40M provide excellent monitoring solutions, the BENTLY Nevada’s scalability and integration capabilities give it a competitive edge in larger operations.

The BENTLY 3500/34 is another model worth mentioning, as it offers robust vibration monitoring; however, it lacks the extensive data analytics features inherent in the BENTLY Nevada. Furthermore, models like the BENTLY 3300/20-12-01-03-00-00 and the BENTLY 3500/42M are excellent for specific applications but do not match the versatility and comprehensive monitoring solutions provided by the BENTLY Nevada.

Related Models

To give you a broader perspective of the BENTLY automation products lineup, here are ten related models that complement the BENTLY Nevada:

1. **BENTLY 3500/20 125744-02**: Ideal for basic monitoring of vibration and temperature.

2. **BENTLY 3500/45 176449-04**: Focused on advanced data analysis for rotating equipment.

3. **BENTLY 3500/40M**: A reliable choice for motor monitoring.

4. **BENTLY 3500/34**: Offers essential vibration monitoring capabilities.

5. **BENTLY 3500/42M**: Known for its advanced monitoring of machinery health.

6. **BENTLY 3500/50**: Provides comprehensive monitoring solutions for various industrial applications.

7. **BENTLY 3500/92**: Designed for high-capacity data collection.

8. **BENTLY 3500/25**: Focuses on temperature monitoring for critical machinery.

9. **BENTLY 3500/53**: Ideal for monitoring pump systems with advanced diagnostics.

10. **BENTLY 3500/72M**: Designed specifically for machinery protection in harsh environments.

In conclusion, the BENTLY Nevada model exemplifies the best of BENTLY automation products, offering advanced monitoring solutions tailored to the needs of modern industries. Its superior features, versatility, and integration capabilities set it apart from other models, making it an indispensable tool for ensuring machinery health and operational efficiency. Whether you are in power generation, oil and gas, manufacturing, or any other sector, the BENTLY Nevada is your go-to solution for proactive maintenance and reliability. Embrace the future of industrial automation with BENTLY Nevada and safeguard your operations today.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the realm of industrial automation and predictive maintenance, the BENTLY Nevada series stands as a benchmark for excellence. Renowned for its unparalleled reliability and advanced monitoring capabilities, the BENTLY Nevada model is engineered to enhance the performance and longevity of critical machinery across various sectors. This product description delves into the key technical features, usage scenarios, comparisons with other models, and a comprehensive overview of related models within the BENTLY automation products lineup.

Key Technical Features

The BENTLY Nevada model is equipped with state-of-the-art technology that ensures precise monitoring and analysis of rotating machinery. Key technical features include:

1. **Advanced Vibration Monitoring**: The BENTLY Nevada employs sophisticated vibration sensors and analytics to detect even the slightest changes in machinery performance. This enables early identification of potential issues before they escalate into costly failures.

2. **Real-Time Data Acquisition**: With its robust data acquisition capabilities, the BENTLY Nevada can provide real-time insights into your machinery's health. This feature is critical for industries where downtime can lead to significant financial losses.

3. **User-Friendly Interface**: The BENTLY Nevada is designed with an intuitive user interface that simplifies monitoring and data interpretation. Operators can easily navigate through the system, ensuring quick access to critical information.

4. **Scalability**: Whether you’re managing a single machine or an entire fleet, the BENTLY Nevada is scalable to meet your needs. This flexibility allows businesses to expand their monitoring capabilities as they grow.

5. **Integration with Existing Systems**: The BENTLY Nevada is compatible with other BENTLY automation products, making it an ideal choice for businesses that already utilize BENTLY solutions. It can seamlessly integrate into existing monitoring frameworks for enhanced efficiency.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide range of applications across various industries. Key usage scenarios include:

– **Power Generation**: In power plants, the BENTLY Nevada monitors turbine and generator performance, ensuring optimal operation and preventing unplanned outages.

– **Oil and Gas**: The model is invaluable in the oil and gas sector, where it safeguards critical machinery such as pumps, compressors, and drilling rigs by providing continuous health assessments.

– **Manufacturing**: In manufacturing environments, the BENTLY Nevada can be used to monitor motors, conveyors, and other moving equipment, ensuring they operate smoothly and efficiently.

– **Water and Wastewater Treatment**: The BENTLY Nevada helps maintain the performance of pumps and treatment equipment, ensuring safe and efficient operations.

– **Mining and Metals**: In the mining sector, it can monitor crushers, conveyors, and other vital equipment, optimizing performance and minimizing downtime.

Comparison with Other Models

When compared to other models within the BENTLY series, the BENTLY Nevada distinguishes itself through its advanced analytics and real-time monitoring capabilities. For example, the BENTLY 3500/20 125744-02 is known for its reliability but may not offer the same level of real-time data and user-friendly interface as the Nevada model. Similarly, while the BENTLY 3500/50 and 3500/40M provide excellent monitoring solutions, the BENTLY Nevada’s scalability and integration capabilities give it a competitive edge in larger operations.

The BENTLY 3500/34 is another model worth mentioning, as it offers robust vibration monitoring; however, it lacks the extensive data analytics features inherent in the BENTLY Nevada. Furthermore, models like the BENTLY 3300/20-12-01-03-00-00 and the BENTLY 3500/42M are excellent for specific applications but do not match the versatility and comprehensive monitoring solutions provided by the BENTLY Nevada.

Related Models

To give you a broader perspective of the BENTLY automation products lineup, here are ten related models that complement the BENTLY Nevada:

1. **BENTLY 3500/20 125744-02**: Ideal for basic monitoring of vibration and temperature.

2. **BENTLY 3500/45 176449-04**: Focused on advanced data analysis for rotating equipment.

3. **BENTLY 3500/40M**: A reliable choice for motor monitoring.

4. **BENTLY 3500/34**: Offers essential vibration monitoring capabilities.

5. **BENTLY 3500/42M**: Known for its advanced monitoring of machinery health.

6. **BENTLY 3500/50**: Provides comprehensive monitoring solutions for various industrial applications.

7. **BENTLY 3500/92**: Designed for high-capacity data collection.

8. **BENTLY 3500/25**: Focuses on temperature monitoring for critical machinery.

9. **BENTLY 3500/53**: Ideal for monitoring pump systems with advanced diagnostics.

10. **BENTLY 3500/72M**: Designed specifically for machinery protection in harsh environments.

In conclusion, the BENTLY Nevada model exemplifies the best of BENTLY automation products, offering advanced monitoring solutions tailored to the needs of modern industries. Its superior features, versatility, and integration capabilities set it apart from other models, making it an indispensable tool for ensuring machinery health and operational efficiency. Whether you are in power generation, oil and gas, manufacturing, or any other sector, the BENTLY Nevada is your go-to solution for proactive maintenance and reliability. Embrace the future of industrial automation with BENTLY Nevada and safeguard your operations today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.