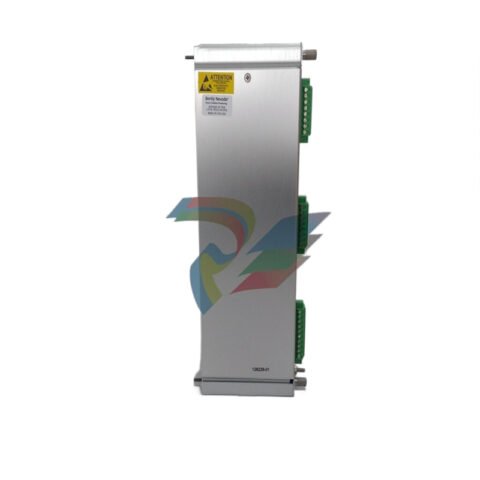

BENTLY Nevada Proximity Sensor 143493-00-080-040-50-00, Advanced Industrial Automation Solution

Introducing the BENTLY Nevada: A Benchmark in Industrial Monitoring Solutions

In the world of industrial automation, precision and reliability are paramount. The BENTLY Nevada model stands as a testament to BENTLY's commitment to delivering cutting-edge technology for monitoring rotating machinery. This product is engineered to enhance operational efficiency, ensuring that your systems run smoothly and effectively.

Key Technical Features

The BENTLY Nevada is characterized by its advanced monitoring capabilities, which include vibration analysis, temperature measurements, and dynamic performance monitoring. Equipped with the latest technology, this model offers comprehensive diagnostics that allow for real-time analysis of machinery conditions.

1. Vibration Monitoring: The BENTLY Nevada integrates sophisticated vibration sensors that provide critical data on the health of rotating machinery. This feature enables early detection of potential failures, minimizing downtime and extending equipment lifespan.

2. Temperature Monitoring: With built-in temperature sensors, the BENTLY Nevada continuously tracks the thermal condition of machinery, ensuring that systems operate within optimal temperature ranges. This capability is essential for preventing overheating and associated damage.

3. User-Friendly Interface: The BENTLY Nevada boasts an intuitive interface that simplifies data interpretation. Users can easily access key performance indicators through its graphical displays, making it straightforward to monitor machinery health at a glance.

4. Integration with BENTLY Automation Products: One of the standout features of the BENTLY Nevada is its seamless integration with other BENTLY automation products. This interoperability enhances overall system efficiency, allowing for a unified approach to machinery monitoring and control.

5. Scalable Architecture: Designed to adapt to various operational scales, the BENTLY Nevada can be deployed in small facilities as well as large industrial complexes. Its scalable architecture ensures that it meets the needs of diverse industries without compromising performance.

Usage Scenarios

The BENTLY Nevada is ideally suited for a variety of industrial applications, including oil and gas, power generation, manufacturing, and water treatment facilities. Here are some specific scenarios where the BENTLY Nevada can significantly enhance operations:

1. Oil and Gas Industry: In this sector, equipment reliability is critical. The BENTLY Nevada's vibration and temperature monitoring capabilities allow for proactive maintenance, reducing the risk of catastrophic failures that can lead to costly production halts.

2. Power Generation: For power plants, the BENTLY Nevada provides essential insights into turbine and generator conditions. By monitoring critical parameters, facility operators can optimize performance and ensure compliance with safety standards.

3. Manufacturing: In high-volume manufacturing environments, the BENTLY Nevada helps maintain machinery efficiency. With its real-time monitoring capabilities, manufacturers can prevent unplanned downtime and improve overall productivity.

4. Water Treatment: The BENTLY Nevada is instrumental in monitoring pumps and motors in water treatment plants. By ensuring that these critical components operate efficiently, the system helps maintain consistent water quality and supply.

Comparison with Other Models

When comparing the BENTLY Nevada to other models within the BENTLY range, it is essential to recognize its unique capabilities and advantages.

For instance, the BENTLY 3500/20 125744-02 excels in providing comprehensive machinery diagnostics but may lack the advanced integration features found in the BENTLY Nevada. Similarly, while the BENTLY 3500/50 offers robust monitoring solutions, it may not provide the same level of user-friendliness and intuitive interface as the BENTLY Nevada.

The BENTLY 330500-00-00, known for its high-performance monitoring, is also a worthy competitor, but the BENTLY Nevada's seamless integration with other BENTLY automation products gives it an edge in holistic system monitoring. Additionally, the BENTLY 3500/40M and BENTLY 3500/34 provide solid performance, yet the advanced features and scalable architecture of the BENTLY Nevada make it a superior choice for industries looking for future-proof solutions.

Related Models

For those exploring the BENTLY Nevada, consider these related models that complement its capabilities:

1. BENTLY 3500/45 176449-04

2. BENTLY 3500/42M

3. BENTLY 3300/16-11-01-03-00-00-01

4. BENTLY 3500/53 133388-01

5. BENTLY 3500/22M

6. BENTLY 3500/72M

7. BENTLY 131151-01

8. BENTLY 3500/15

9. BENTLY 3500/25-01-00-00

10. BENTLY 3500/92

These models each offer unique features and benefits that can be integrated with the BENTLY Nevada, providing a comprehensive suite of monitoring solutions tailored to your specific industrial needs.

In conclusion, the BENTLY Nevada is a premier choice for industries seeking advanced monitoring solutions that prioritize reliability, efficiency, and integration. With its robust technical features and versatile applications, the BENTLY Nevada is positioned to transform your machinery monitoring strategy, ensuring optimal performance and peace of mind. Upgrade your industrial automation today with the unparalleled capabilities of the BENTLY Nevada, and experience the difference that precision monitoring can make.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the world of industrial automation, precision and reliability are paramount. The BENTLY Nevada model stands as a testament to BENTLY's commitment to delivering cutting-edge technology for monitoring rotating machinery. This product is engineered to enhance operational efficiency, ensuring that your systems run smoothly and effectively.

Key Technical Features

The BENTLY Nevada is characterized by its advanced monitoring capabilities, which include vibration analysis, temperature measurements, and dynamic performance monitoring. Equipped with the latest technology, this model offers comprehensive diagnostics that allow for real-time analysis of machinery conditions.

1. Vibration Monitoring: The BENTLY Nevada integrates sophisticated vibration sensors that provide critical data on the health of rotating machinery. This feature enables early detection of potential failures, minimizing downtime and extending equipment lifespan.

2. Temperature Monitoring: With built-in temperature sensors, the BENTLY Nevada continuously tracks the thermal condition of machinery, ensuring that systems operate within optimal temperature ranges. This capability is essential for preventing overheating and associated damage.

3. User-Friendly Interface: The BENTLY Nevada boasts an intuitive interface that simplifies data interpretation. Users can easily access key performance indicators through its graphical displays, making it straightforward to monitor machinery health at a glance.

4. Integration with BENTLY Automation Products: One of the standout features of the BENTLY Nevada is its seamless integration with other BENTLY automation products. This interoperability enhances overall system efficiency, allowing for a unified approach to machinery monitoring and control.

5. Scalable Architecture: Designed to adapt to various operational scales, the BENTLY Nevada can be deployed in small facilities as well as large industrial complexes. Its scalable architecture ensures that it meets the needs of diverse industries without compromising performance.

Usage Scenarios

The BENTLY Nevada is ideally suited for a variety of industrial applications, including oil and gas, power generation, manufacturing, and water treatment facilities. Here are some specific scenarios where the BENTLY Nevada can significantly enhance operations:

1. Oil and Gas Industry: In this sector, equipment reliability is critical. The BENTLY Nevada's vibration and temperature monitoring capabilities allow for proactive maintenance, reducing the risk of catastrophic failures that can lead to costly production halts.

2. Power Generation: For power plants, the BENTLY Nevada provides essential insights into turbine and generator conditions. By monitoring critical parameters, facility operators can optimize performance and ensure compliance with safety standards.

3. Manufacturing: In high-volume manufacturing environments, the BENTLY Nevada helps maintain machinery efficiency. With its real-time monitoring capabilities, manufacturers can prevent unplanned downtime and improve overall productivity.

4. Water Treatment: The BENTLY Nevada is instrumental in monitoring pumps and motors in water treatment plants. By ensuring that these critical components operate efficiently, the system helps maintain consistent water quality and supply.

Comparison with Other Models

When comparing the BENTLY Nevada to other models within the BENTLY range, it is essential to recognize its unique capabilities and advantages.

For instance, the BENTLY 3500/20 125744-02 excels in providing comprehensive machinery diagnostics but may lack the advanced integration features found in the BENTLY Nevada. Similarly, while the BENTLY 3500/50 offers robust monitoring solutions, it may not provide the same level of user-friendliness and intuitive interface as the BENTLY Nevada.

The BENTLY 330500-00-00, known for its high-performance monitoring, is also a worthy competitor, but the BENTLY Nevada's seamless integration with other BENTLY automation products gives it an edge in holistic system monitoring. Additionally, the BENTLY 3500/40M and BENTLY 3500/34 provide solid performance, yet the advanced features and scalable architecture of the BENTLY Nevada make it a superior choice for industries looking for future-proof solutions.

Related Models

For those exploring the BENTLY Nevada, consider these related models that complement its capabilities:

1. BENTLY 3500/45 176449-04

2. BENTLY 3500/42M

3. BENTLY 3300/16-11-01-03-00-00-01

4. BENTLY 3500/53 133388-01

5. BENTLY 3500/22M

6. BENTLY 3500/72M

7. BENTLY 131151-01

8. BENTLY 3500/15

9. BENTLY 3500/25-01-00-00

10. BENTLY 3500/92

These models each offer unique features and benefits that can be integrated with the BENTLY Nevada, providing a comprehensive suite of monitoring solutions tailored to your specific industrial needs.

In conclusion, the BENTLY Nevada is a premier choice for industries seeking advanced monitoring solutions that prioritize reliability, efficiency, and integration. With its robust technical features and versatile applications, the BENTLY Nevada is positioned to transform your machinery monitoring strategy, ensuring optimal performance and peace of mind. Upgrade your industrial automation today with the unparalleled capabilities of the BENTLY Nevada, and experience the difference that precision monitoring can make.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.